Roll Mining Mill Versus Gyratorty Mining Mill

blake type roll mining mill and the gyratory mining mill

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Grinding mills for mining and minerals processing

Mill liners Metallic, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types. Grinding mill upgrades Whether old or new, we can help bring your grinding mill

Blake Type Roll Mining Mill And The Gyratory Mining Mill

Rod mills how they function Mine . Rod mills are very similar to ball mills except they use long rods for grinding media The rods grind the ore by tumbling within the the mill similar

mining gyratory grindings ball mills comparison

Contribute to lbsid/en development by creating an account on GitHub.

Mill (grinding) Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many

roll cone and gyratory mining mills in relation to mining

Largest Gyratory Crusher Crusher Mills, Cone . CG series of primary gyratory crushers Mining and . gyratory crushers, the benefi ts are well established. By combining leading

difference between roll mining mill and gyratory mining mill

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

广东省区县工业百强出炉!宝安南山龙岗龙华光明上榜十

宝安南山龙岗龙华光明上榜十. 近日,赛迪顾问广东分支机构正式发布《2022广东省区县工业百强研究》。. 深圳市宝安区、南山区、龙岗区、龙华区、光明区上榜评估结果名单

How Ball Mills Work (Engineering and Mining) YouTube

2019年6月20日Want to continue learning about engineering with videos like this one? Then visit:https://courses.savree/ Want to teach/instruct with the 3D models

Roller mill Wikipedia

Roller mill. An early 20th-century oil-seed roller-mill from the Olsztyn district, Poland. A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022. Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York. Cutaway drawing of a centrifugal roller mill for mining applications, 1913.

AMIT 135: Lesson 5 Crushing Mining Mill Operator

Lower installed cost than gyratory crushers. Can handle high abrasion with low maintenance. Jaw Crusher Disadvantages Maximum capacity of 1,000 MTPH. Can be used for primary crushing only. Gyratory Crushers

MineMill Equipment Cost Guide Costmine

The MineMill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations. Select from a full range of sizes and types, with

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Gyratory crusher: feed diameter 0.75 to 1.5m; reduction ratio 5:1 to 10:1, usually 8:1; capacity 140 to 1000 kg/s; Mohs hardness <9. More suitable for slabby feeds than jaw crusher. [reduction by compression]. Roll crusher: feed diameter 1 cm: reduction ratio 5:1 to 10:1; capacity 0.3 to 20 kg/s: Mohs hardness < 7.5.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Advantages of Stirred Mills (VERTIMILL ®): Lower installation cost Lower operation cost Higher efficiency Less floor space Simple foundation Less noise Few moving parts Less overgrinding Better operation safety

mining gyratory grindings ball mills comparison github

Contribute to lbsid/en development by creating an account on GitHub.

Mill (grinding) Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

roll cone and gyratory mining mills in relation to mining

Largest Gyratory Crusher Crusher Mills, Cone . CG series of primary gyratory crushers Mining and . gyratory crushers, the benefi ts are well established. By combining leading . largest, the CG880, is one of the most powerful gyratory crushers in the world.

difference between roll mining mill and gyratory mining mill

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

SAG Mill Autogenous and Semi-Autogenous Mills

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. Fuller

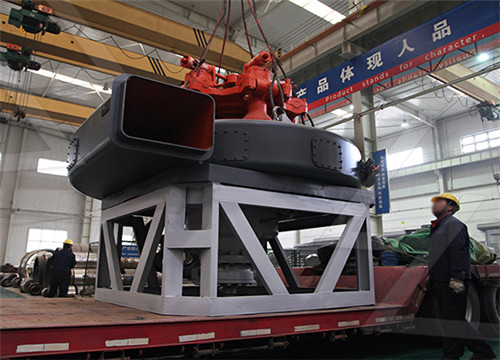

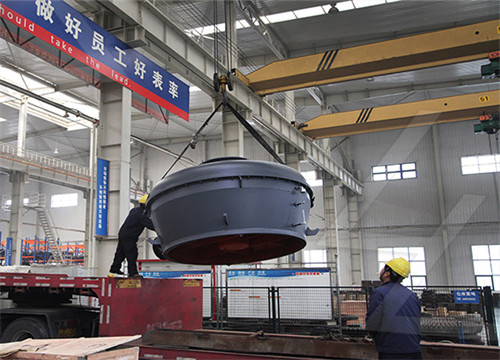

Gyratory Crusher Functional Diagram Crusher Mills, Cone

simple image diagram of gyotery crusher- [crusher and mill] A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. . Figure 6.7 Gyratory crusher: (a) functional diagram, (b .

Difference Between Roll Mining Mill And Gyratory Mining Mill.Pdf

Different Between Roll Mining Mill And Ball Mill. Different Between Roll Mining Mill And Ball Mill. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon HGT gyratory crusher has many incomparable advantages such as high crushing efficiency, low production cost and simple maintenance method, which can satisfy the requirements

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The common primary crushers are of jaw and gyratory types.

en/related theory of roll mining mill at.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Roller mill Wikipedia

Roller mill. An early 20th-century oil-seed roller-mill from the Olsztyn district, Poland. A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022. Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York. Cutaway drawing of a centrifugal roller mill for mining applications, 1913.

MineMill Equipment Cost Guide Costmine

The MineMill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations. Select from a full range of sizes and types, with

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Advantages of Stirred Mills (VERTIMILL ®): Lower installation cost Lower operation cost Higher efficiency Less floor space Simple foundation Less noise Few moving parts Less overgrinding Better operation safety

SAG Mill Autogenous and Semi-Autogenous Mills

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. Fuller

Stamp mill Wikipedia

A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic ores. Breaking material down is a

Gyratory Crusher Functional Diagram Crusher Mills, Cone

simple image diagram of gyotery crusher- [crusher and mill] A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. . Figure 6.7 Gyratory crusher: (a) functional diagram, (b .

Difference Between Roll Mining Mill And Gyratory Mining Mill.Pdf

Different Between Roll Mining Mill And Ball Mill. Different Between Roll Mining Mill And Ball Mill. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon HGT gyratory crusher has many incomparable advantages such as high crushing efficiency, low production cost and simple maintenance method, which can satisfy the requirements

roll cone and gyratory mining mills in relation to mining

Largest Gyratory Crusher Crusher Mills, Cone . CG series of primary gyratory crushers Mining and . gyratory crushers, the benefi ts are well established. By combining leading . largest, the CG880, is one of the most powerful gyratory crushers in the world.

difference between roll mining mill and gyratory mining mill

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The common primary crushers are of jaw and gyratory types.

Gyratory Crusher an overview ScienceDirect Topics

Jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones. This is generally followed by a cone crusher. A combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh (45 μm). Instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dusting.

en/related theory of roll mining mill at.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

The Weir Group Engineered Solutions For Industrial Markets

The Weir Group Engineered Solutions For Industrial Markets