Cement Crusher Risks

HSE Quarries Safe operation and use of mobile jaw

Key risks Machinery guarding Clearing Blocked or Stalled Crushers Slips and trips Transport coming in to contact with excavators loading the crusher Mobile crushers

Concrete and Concrete Products Overview

根据热度为您推荐•反馈

Safe and sound: Crusher safety : PitQuarry

2015年7月14日New equipment and technologies have emerged to minimize some of the dangers associated with clearing a blocked crusher. These have surely eliminated some

Concrete and Concrete Products Overview

Concrete is one of the most widely used construction materials in the world. Safety issues exist in all phases of concrete production, including the manufacture of portland cement and pre-cast concrete products, as well

Safe and sound: Crusher safety : PitQuarry

2015年7月14日New equipment and technologies have emerged to minimize some of the dangers associated with clearing a blocked crusher. These have surely eliminated some accidents and enhanced worker safety. Still, a crusher accident can happen in a moment’s notice. When a worker makes a poor decision. When someone is in a rush.

Crushing and Screening Safety is our #1 Priority

2017年9月20日Crushing is a dangerous business. Every year there are serious accidents on the job site and some are fatal. Nearly all could have been avoided with better safe work practices. Just this past June, the Mine Safety and Health Administration (MSHA) issued a Serious Accident Alert after a worker was trying to unplug a portable crusher.

Risk Assessment in Cement Manufacturing Process IJERT

- 25),to reduce this risk to take immediate action is required using safety control measures. Risks should be minimized as an acceptable level to manage it (1-4). 2. To minimize the risks, risk control can involve evaluation, and compliance with decisions. 3. Proper action is necessary to implementing risk

Guidelines for Management Crushing and Screening final feb10

ejected from crushers and maintenance tasks all need careful management. 4.1 Crusher Blockage. A. Clearing blocked jaw crushers can be very hazardous and many plant operators have been killed carrying out this task. Blockage incidents can be greatly reduced by supplying rock that is properly sized to match the primary jaw opening.

Risk And Hazards Associated With Concrete Cutting

2013年8月5日People who regularly work with concrete and masonry drilling and cutting equipment are at high risk of wide range of hazards, like silica dust, saw kick back, toxic exhaust fumes, collapsing walls, blade

CRUSHER RISKHAZARD ASSESSMENT

CRUSHER..Ph..0475 217 533..Risk and Hazard Assessment is the identification of risks and hazards associated with the CRUSHER. Compliant Industries Group hazard and risk assessors are experienced

Environmental Devices

Key Words: Air quality index, cement industry, health risk assessment, haz-dust EPAM- 5000, particulate matter, PM 2.5, PMI 0. Introduction The health effects caused by air pollution may Tertiary Crusher Cooler Clinker Yard 1 Cement Mil Silos Packing Section Raw Mill Kiln Clinker Yard 2 Main crusher (pg/m3) 1148.0 1329.0 688.0 908.0 301.0

concrete crusher risk assessment kooks.co.za

concrete crusher risk assessment. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size HSE Quarries Safe operation and use of mobile jaw Safe operation and use of mobile jaw crushers Scope of this guidance .

risks in crusher area in cement plant -china

cement crusher risks, Ciros crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher Go to Product Center. function of fls crusher at mines in cement plant Machine, Engineering, Cement, Metals Functional Area : Production, Manufacturing

Concrete crusher in Detroit would be health hazard

2022年12月15日Particulate matter kills. In children it exacerbates asthma. In adults it leads to chronic lung disease which, over time, can stress the heart as it struggles to push blood through increasingly...

Environmental GUIDELINE ON STONE CRUSHING plant

usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making. Fine aggregates are used for the production of concrete and plastering. Provision for a proper drainage scheme for evacuation of stormwater to avoid any risks of flooding/water-logging of site and adjoining areas to

(PDF) Assessing and Ranking Health, Safety and Environmental Risks

2020年1月1日PDF On Jan 1, 2020, Hossein Armin and others published Assessing and Ranking Health, Safety and Environmental Risks through Analytical Network Process (ANP) Method in Cement Plant in 2020 Find

IJERPH Free Full-Text Platinum Mine Workers’ Exposure to Dust

2020年1月19日The South African mining industry is one of the largest producers of platinum (Pt) in the world. Workers in this industry are exposed to significant amounts of dust, and this dust consists of particles sizes that can penetrate deep inside the respiratory region. A cross-sectional study was conducted to evaluate dust exposure risk at two Pt

Crushing and Screening Safety is our #1 Priority

2017年9月20日Crushing is a dangerous business. Every year there are serious accidents on the job site and some are fatal. Nearly all could have been avoided with better safe work practices. Just this past June, the Mine Safety and Health Administration (MSHA) issued a Serious Accident Alert after a worker was trying to unplug a portable crusher.

Risk Assessment in Cement Manufacturing Process IJERT

- 25),to reduce this risk to take immediate action is required using safety control measures. Risks should be minimized as an acceptable level to manage it (1-4). 2. To minimize the risks, risk control can involve evaluation, and compliance with decisions. 3. Proper action is necessary to implementing risk

Guidelines for Management Crushing and Screening final feb10

ejected from crushers and maintenance tasks all need careful management. 4.1 Crusher Blockage. A. Clearing blocked jaw crushers can be very hazardous and many plant operators have been killed carrying out this task. Blockage incidents can be greatly reduced by supplying rock that is properly sized to match the primary jaw opening.

(PDF) Assessing and Ranking Health, Safety and Environmental Risks

2020年1月1日PDF On Jan 1, 2020, Hossein Armin and others published Assessing and Ranking Health, Safety and Environmental Risks through Analytical Network Process (ANP) Method in Cement Plant in 2020 Find

CRUSHER RISKHAZARD ASSESSMENT

CRUSHER..Ph..0475 217 533..Risk and Hazard Assessment is the identification of risks and hazards associated with the CRUSHER. Compliant Industries Group hazard and risk assessors are experienced

Environmental Devices

Key Words: Air quality index, cement industry, health risk assessment, haz-dust EPAM- 5000, particulate matter, PM 2.5, PMI 0. Introduction The health effects caused by air pollution may Tertiary Crusher Cooler Clinker Yard 1 Cement Mil Silos Packing Section Raw Mill Kiln Clinker Yard 2 Main crusher (pg/m3) 1148.0 1329.0 688.0 908.0 301.0

Crushing And Screening Equipment Importance

2014年12月9日Moreover, when there is a complete risk assessment, concrete and effective actions can be taken in order to keep the workers protected and safe from any risks. The risk assessment involves

baseline risk assessment for crushing plant MiningQuarry

2013年4月27日Use of Screening Machine and Crusher; Risk assessment ‘A crushing plant operator tried to ‘nip’ some rock that was not passing into the crusher jaws. cement plant risk assessment Crusher South Africa. Ore Crushing; Mobile Crushing Plant; Crushing News. TITLE DATE December 21, 2012 cement plant risk assessment; 4.8

concrete crusher risk assessment kooks.co.za

concrete crusher risk assessment. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size HSE Quarries Safe operation and use of mobile jaw Safe operation and use of mobile jaw crushers Scope of this guidance .

risks in crusher area in cement plant -china

cement crusher risks, Ciros crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher Go to Product Center. function of fls crusher at mines in cement plant Machine, Engineering, Cement, Metals Functional Area : Production, Manufacturing

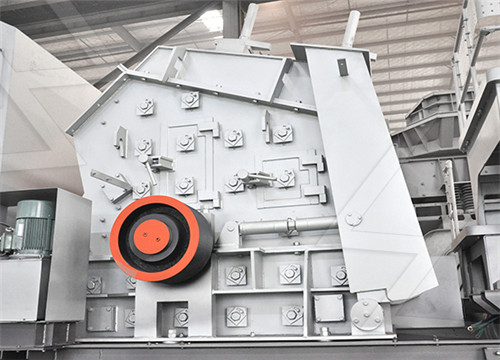

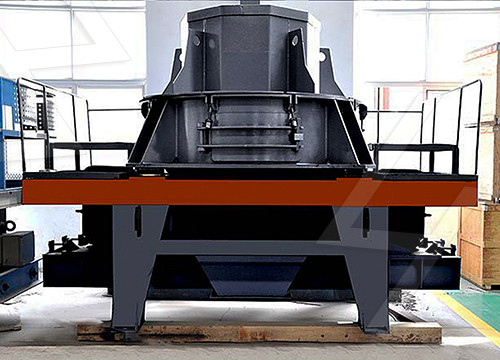

Cement Crusher Crusher In Cement Plant AGICO Cement

Materials with weak abrasiveness are usually broken by impact or grinding method. The crushing part should have sharp teeth. The hard materials with smaller particle sizes are generally crushed by extrusion or impact method. The surface of the crushing part is smooth and toothless, such as roller crusher.

Risk Assessment in Cement Manufacturing Process IJERT

2019年12月4日Jousi A., Risk engineering is an important role in cement manufacturing process to eliminate the hazards, examine the performance, to analysis the losses, identify the hazards, providing recommendation, proper record keeping maintained (previous records), Risk engineering. Control all the tasks such as guarding information, behavior

Environmental GUIDELINE ON STONE CRUSHING plant

usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making. Fine aggregates are used for the production of concrete and plastering. Provision for a proper drainage scheme for evacuation of stormwater to avoid any risks of flooding/water-logging of site and adjoining areas to

IJERPH Free Full-Text Platinum Mine Workers’ Exposure to Dust

2020年1月19日The South African mining industry is one of the largest producers of platinum (Pt) in the world. Workers in this industry are exposed to significant amounts of dust, and this dust consists of particles sizes that can penetrate deep inside the respiratory region. A cross-sectional study was conducted to evaluate dust exposure risk at two Pt