Copper Floatation And Gold Separation Setup Of Stone Crusher Unit

Separating Minerals by Floatation ABB

goes on to another separation process or to waste. The ability of a mineral to float depends on certain conditions. One important floatation variable is pH, which affects: − the form

Crushing Plant FlowsheetDesign-Layout Mineral

Crusher Plant LayoutCrushingScreeningTo reduce run-of-mine to mill feed requires reduction in a series of stages. The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application. Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushing. In the maj...

Copper Flotation Mineral ProcessingMetallurgy

2016年5月16日Copper Flotation Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as

Mineral Comminution and Separation Systems EOLSS

In the present flowsheet, flotation plays the main role in separation (or concentration). In this flowsheet we can find two types of flotation equipment, the conventional flotation

Copper Mining and Processing: Processing Copper Ores

The slurry is placed in a tank and a process called froth floatation is used to separate the copper minerals from the gangue. Chemical reagents called “collectors” are added to the

Frothers, Bubbles and Flotation NPS History

effective in processing gold ore, flotation opened the minerals market. Metal production was increased to 24 metallic and 19 non-metallic minerals by the mid-twentieth century.

Hardrock Gold Mill, Crusher, Ball Mill, Gold Shaker Table,

2011年11月19日A custom hardrock gold mill in MT, USA milling gold and silver ore through: Jaw crusher, Cone Crusher, Ball Mill, Jig, Shaker Tables, and Flotation Cells. T...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipments. Crushing is the

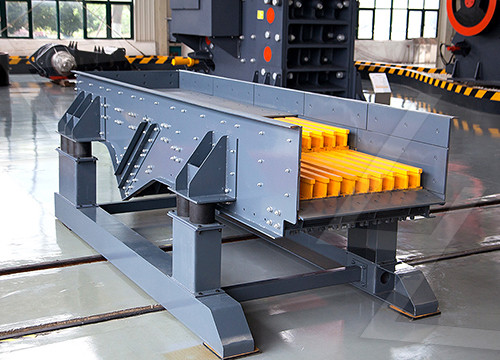

Flotation Separation Production Line

Flotation separation production line can be widely used for separating copper, gold, fluorite, sulphid, phosphorous and so on. It can maximize the enrichment of minerals. In

A Review of the Flotation of Copper Minerals

2017年7月4日The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 0.5%TCu (open pit mines) and 1-2%TCu (underground mines) is of great commercial importance....

Separating Minerals by Floatation ABB

goes on to another separation process or to waste. The ability of a mineral to float depends on certain conditions. One important floatation variable is pH, which affects: − the form of many ionic species present − the charge state of the mineral surfaces − the form of many collectors. Separating Minerals by Floatation Copper processing

1 Froth Flotation Fundamental Principles

After carrying out a froth flotation separation, the products are as shown in Table 1. Using this data, calculate: (a) Ratio of concentration (b) % Metal Recovery (c) % Metal Loss (d) % Weight Recovery, or % Yield (e) Enrichment Ratio Table 1: Grade/recovery performance of a hypothetical copper ore flotation process.

Mineral Processing Flowsheets

2016年3月8日The Flotation Machine, the Selective Mineral Jig and the Unit Flotation Cell have revolutionized flowsheet design and have made it possible for both small and large plants to increase recoveries and economical return. The Unit Flotation Cell and the Selective Mineral Jig have been perfected to meet the most important principle in ore

Mineral Comminution and Separation Systems EOLSS

In the present flowsheet, flotation plays the main role in separation (or concentration). In this flowsheet we can find two types of flotation equipment, the conventional flotation machines 19-22 and flotation columns 13-14 that represent relatively newly introduced type of the equipment.

Flotation Reagents Mineral ProcessingMetallurgy

2016年6月8日Promoter for gold, silver, copper and zinc sulphide ores. Stronger than sodium aerofloat. Aerofloat 208: A non-frothing water soluble dry aerofloat. 5-10% solution .01 to .10: Alone or in the combination with reagent 301 is widely used for flotation of gold and silver. Aerofloat 211: A water soluble dry aerofloat. Formerly sodium aerofloat B.

An Overview of Basic Gold Separation Methods

2016年3月14日The flotation method involves mixing your crushed ore with water and then you add frothing agents in a single floatation machine. You then use a tube to release air into the floatation machine. This creates air bubbles to the bottom of the machine and this helps attach hydrophilic materials such as gold to the bubbles and thus float on the

Hardrock Gold Mill, Crusher, Ball Mill, Gold Shaker Table, Flotation

2011年11月19日112K subscribers A custom hardrock gold mill in MT, USA milling gold and silver ore through: Jaw crusher, Cone Crusher, Ball Mill, Jig, Shaker Tables, and Flotation Cells. This

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. [1] Depending on the processes used in each instance, it is often also known as ore dressing or ore milling .

ISMAIL HAKAN BUZCU Concentrator Operation Manager/Flotation Copper

1-Establish pyrite and zinc flotation system and tank leaching gold-silver with flotation tail. 2-Create Gold Flotation System 3-Cyanide detox system set up More activity by ISMAIL...

mill/sbm professional gold ore flotation machine gold

Contribute to crush2022/mill development by creating an account on GitHub.

mill/sbm copper gold floatation separator.md at master mill

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

en/gold copper floatation.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

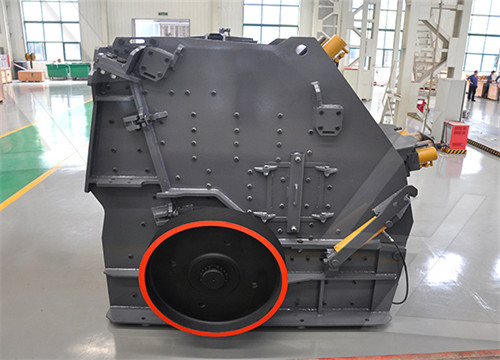

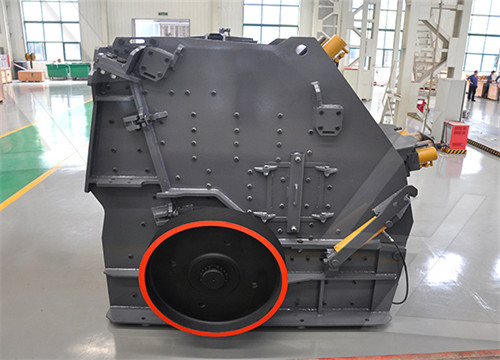

Jaw Crusher|Impact Crusher|Hammer Crusher|Stone Production

Stone crusher is an important equipment in mining operation, stone crusher made in Hongrun can be jaw crusher, hammer crusher, impact crusher, double-shaft crusher, vertical crusher, etc. These stone crushers are used for stone/minera + Mineral Production Line. In Hongrun, you will find we provide various complete mining production

A Review of the Flotation of Copper Minerals

2017年7月4日The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 0.5%TCu (open pit mines) and 1-2%TCu (underground mines) is of great commercial importance....

Separating Minerals by Floatation ABB

goes on to another separation process or to waste. The ability of a mineral to float depends on certain conditions. One important floatation variable is pH, which affects: − the form of many ionic species present − the charge state of the mineral surfaces − the form of many collectors. Separating Minerals by Floatation Copper processing

Mineral processing Wikipedia

Mineral processing can involve four general types of unit operation: comminution particle size reduction; sizing separation of particle sizes by screening or classification; concentration by taking advantage of

Mineral Comminution and Separation Systems EOLSS

In the present flowsheet, flotation plays the main role in separation (or concentration). In this flowsheet we can find two types of flotation equipment, the conventional flotation machines 19-22 and flotation columns 13-14 that represent relatively newly introduced type of the equipment.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipments. Crushing is the first step of mineral processing where

Flotation Reagents Mineral ProcessingMetallurgy

2016年6月8日Promoter for gold, silver, copper and zinc sulphide ores. Stronger than sodium aerofloat. Aerofloat 208: A non-frothing water soluble dry aerofloat. 5-10% solution .01 to .10: Alone or in the combination with reagent 301 is widely used for flotation of gold and silver. Aerofloat 211: A water soluble dry aerofloat. Formerly sodium aerofloat B.

An Overview of Basic Gold Separation Methods

2016年3月14日The flotation method involves mixing your crushed ore with water and then you add frothing agents in a single floatation machine. You then use a tube to release air into the floatation machine. This creates air bubbles to the bottom of the machine and this helps attach hydrophilic materials such as gold to the bubbles and thus float on the

Froth Flotation Process Mineral ProcessingMetallurgy

2021年1月20日The process of froth flotation usually involves a series of steps: the preparation of appropriate particle sizes of liberated components in the mixture of solids to be separated; the creation of conditions favourable for the adherence of one or more components in the mixture of solids to attach to air bubbles; and.

crushing and separation of gold from rocks machine stone crusher

crushing and separation of gold from rocks machine stone crusher machine. 250tph river stone crushing line in Chile. electrical, automated, intelligent control technology together. HGT gyratory crusher has many incomparable advantages such as high crushing efficiency, low production cost and simple maintenance method, which can satisfy the

Kurmel Holding Gümüştaş Mining

GUMUSHANE POLYMETALLIC LEAD ZINC COPPER OPERATIONS. Gumustas Gumushane Mining site is located 2 km southwest of Gumushane in the Eastern Black Sea Region. Our license #IR-8479 covers the locality of Hazine Magarasi which was an ancient mine operation from 1200s. It is described as polymetallic Pb-Zn-Cu (Au-Ag) deposit.

mill/sbm professional gold ore flotation machine gold

Contribute to crush2022/mill development by creating an account on GitHub.

Estimation on separation efficiency of aluminum from base-cap

In order to separate aluminum from the base-cap of spent fluorescent lamp (SFL), the separation efficiency of hammer crusher unit is estimated by introducing a binary separation theory. The base-cap of SFL is composed by glass fragment, binder, ferrous metal, copper and aluminum. The hammer crusher

Copper Floatation And Gold Separation animclass

Mining industry copper sulfide ore and flotation process ,jul 09, 2019 copper-cobalt ore copper mineral and cobalt-containing pyrite and other cobalt minerals. arsenic sulfide copper ore the ore has a high content of arsenic, which is mainly in the form of arsenopyrite. flotation process to solve the problem of copper and arsenic separation, reduce the

Jaw Crusher|Impact Crusher|Hammer Crusher|Stone Production

Stone crusher is an important equipment in mining operation, stone crusher made in Hongrun can be jaw crusher, hammer crusher, impact crusher, double-shaft crusher, vertical crusher, etc. These stone crushers are used for stone/minera + Mineral Production Line. In Hongrun, you will find we provide various complete mining production