Quarry Crusher Choice

New crusher improves quarry efficiency and operator safety

2021年12月13日The crusher has been designed to consume both less energy and hydraulic oil. For operator safety, it is equipped with spacious platforms which provide

进一步探索

Download center — Mining and Rock TechnologyJaw Crusher Series Technical Specification根据热度为您推荐•反馈

Quarry Crusher- Differences between Three Kinds Of Crushers

根据热度为您推荐•反馈

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce

Simplifying the crushing process PitQuarry : Pit

2019年5月10日1. Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary

Primary Crushing Mineral ProcessingMetallurgy

2016年2月26日The choice of a primary breaker is an individual problem for every installation. The type of mining and the regularity, size, and rate at which the ore is delivered, are the main determining factors, but all local

Quarry Stone Crusher Mortar Plant

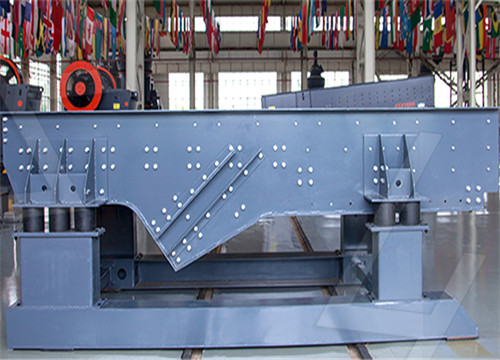

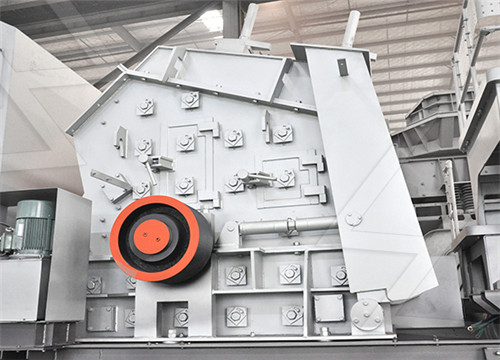

2021年12月3日Impact crusher is one of the most common quarry stone crushing machines, mainly by the base, shaft, hydraulic cylinder, rear frame, impact frame, impact

Amazing Quarry Primary Rock Crushing Machine

2020年6月19日Amazing Quarry Primary Rock Crushing Machine Working, Stone Processing by Crusher YouTube 0:00 10:53 Amazing Quarry Primary Rock Crushing

Crushed Stone Description and Uses (Pennsylvania locations)

Quarry/Crusher Run x Fill material, roadway sub-grade, compactable, some clay content possible R-3 Rip Rap x 3" 6" Ballast to fill gabion baskets, stabilize earthprevent

Rock Quarry Crushing Operations HD YouTube

2018年1月3日Watch in HD, shows how large hard rock is crushed down to smaller rock. Rock is blasted and mined, then hauled up above to be sent to the crusher, jaw -- scr...

New crusher improves quarry efficiency and operator safety

2021年12月13日The crusher has been designed to consume both less energy and hydraulic oil. For operator safety, it is equipped with spacious platforms which provide safe access for service and maintenance. The new impact crusher is the first in the 3-Series 3rd Generation crusher range from and targeted at quarry, recycling and contractor

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

The Complete Guide to Crushed Stone and Gravel gra

2019年11月11日Most crushed stone is produced in quarries and is crushed when machinery breaks up and crushes larger rocks. Instead of being shaped or formed naturally, such as in a riverbed or canyon,

® C Series™ jaw crushers Proven reliability and

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

The difference between stone hammer crusher and impact crusher

2023年3月10日For those looking to crush softer materials at a lower cost, a stone hammer crusher may be the better choice. However, for those looking to crush harder materials at a faster rate with a more

Quarry Stone Crusher Mortar Plant

2021年12月3日Impact crusher is one of the most common quarry stone crushing machines, mainly by the base, shaft, hydraulic cylinder, rear frame, impact frame, impact frame, front frame, rotor frame, front frame hydraulic cylinder, and other components. Features of impact crusher

Amazing Quarry Primary Rock Crushing Machine Working, Stone YouTube

2020年6月19日Amazing Quarry Primary Rock Crushing Machine Working, Stone Processing by Crusher YouTube 0:00 10:53 Amazing Quarry Primary Rock Crushing Machine Working,

Quarry 2020 Mobile CrushersScreens Guide

2020年1月1日10 Quarry 2020 Guide to Mobile Plant. Application: Sand and gravel, blasted rock, river rock, C&D materials, overburden, foundry waste, processed minerals Output (tph): 350 Maximum Feed size (mm

Stone Jaw Crusher Machine, Mining Aggregate Quarry Limestone

2023年3月9日Jaw crusher can be used for processing granite, marble, basalt, limestone, quartz, river pebble, iron ore, copper ore and other materials. Generally used as

Quarry Crawler Type Portable Stone Jaw Crusher Machine

Features of Our Crawler Mobile Crusher. 1. Strong power of diesel engines, Low fuel consumption and noise, powerful horsepower, energy saving and high yield. 2. Convenient and fast, Outlet size can be controlled by hydraulic, with advantages of convenient and fast. 3. Intelligent operation With wireless remote control, self-tracked walking.. 4. All-steel

Mobile crushers and screens — SRP

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a crusher or screening aggregates after a crusher. Every product is backed by unrivaled aftermarket support to help keep your equipment running at optimum levels

Simplifying the crushing process PitQuarry : PitQuarry

2019年5月10日1. Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher. Typically, the minimum setting on most primary crushers is about 4 in. to 6 in. Jaw, gyratory and impact crushers are most often appropriate as primary crushers, although there

Crushers Omnia Machinery

Crushers are heavy duty machines designed to crush large debris into smaller, manageable rubble such as gravel, sand and dust. These types of machines are brought onto a project to change the form of waste materials, ensuring they can be disposed of or recycled accordingly. At Omnia Machinery we stock a vast range of used crushers including,

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Mobile crushers and screens — SRP

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a crusher or screening aggregates after a

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

® C Series™ jaw crushers Proven reliability and

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Pennsylvania Crusher Handbook of Crushing TerraSource Global

Pennsylvania Crusher Handbook of Crushing TerraSource Global

The difference between stone hammer crusher and impact crusher

2023年3月10日For those looking to crush softer materials at a lower cost, a stone hammer crusher may be the better choice. However, for those looking to crush harder materials at a faster rate with a more

Quarry 2020 Mobile CrushersScreens Guide

2020年1月1日10 Quarry 2020 Guide to Mobile Plant. Application: Sand and gravel, blasted rock, river rock, C&D materials, overburden, foundry waste, processed minerals Output (tph): 350 Maximum Feed size (mm

The Secrets of The Yard Quarry Crushers and Yard Organization

2023年1月18日Quarry crushers play the most pivotal role. Learn the secrets of the yard in Episode 4 of “The Secret Life of Quarries.” Visit https://bit.ly/3M6DcK3 Show more Show more Best-Kept Productivity...

Stone Jaw Crusher Machine, Mining Aggregate Quarry Limestone

2023年3月9日Jaw crusher can be used for processing granite, marble, basalt, limestone, quartz, river pebble, iron ore, copper ore and other materials. Generally used as

Quarry Crusher Choice fitnessfreaks

Quarry Crusher is the first choice for primary crushing which is capable of crushing hard rock and wear We would like to achieve a qualitative leap in terms of quality necessary to the good relations now Stone Quarry Crushing Plant For Sale In Zambia good quality quarry stone crusher machine in quarries lead to cone crusher.

The pros and cons of cone crusher applications Quarry

2021年4月16日Operating a tertiary cone crusher in a closed circuit provides consistent input gradation and improves the shape by attrition crushing. 9. Operate the crusher at the correct speed for the application. Running the crusher too fast can generate excessive fines because the material cannot fall as far with each revolution of the eccentric.

Quarry Crawler Type Portable Stone Jaw Crusher Machine

Features of Our Crawler Mobile Crusher. 1. Strong power of diesel engines, Low fuel consumption and noise, powerful horsepower, energy saving and high yield. 2. Convenient and fast, Outlet size can be controlled by hydraulic, with advantages of convenient and fast. 3. Intelligent operation With wireless remote control, self-tracked walking.. 4. All-steel

Quarry Omnia Machinery

The materials extracted include limestone, granite, marble and sand. The equipment and machinery used in quarrying are Screens, crushers, shredders and rock drills. We provide all the leading manufacturers such as: Extec, Tesab, Fintec, Brown Lennox, Pegson, and -Finlay.

Crushers Omnia Machinery

Home Machines Quarry Crushers Crushers Crushers are heavy duty machines designed to crush large debris into smaller, manageable rubble such as gravel, sand and dust. These types of machines are brought onto a project to change the form of waste materials, ensuring they can be disposed of or recycled accordingly.