Roll Crusher 47mth5u5 Toothed Roll

Single Roll Crushers McLanahan

根据热度为您推荐•反馈

Roll Crusher an overview ScienceDirect Topics

Toothed crushing rolls ( Figure 6.16) are typically used for coarse crushing of soft or sticky iron ores, friable limestone or coal, where rolls of ca. 1 m diameter are used to crush

进一步探索

Roll CrushersRoll crushers SlideShare根据热度为您推荐•反馈

Mid-range rolls crushers tough on any material

The Essa Rolls Crusher range includes: Essa RC2000 Rolls Crusher compact and rapid standalone rolls crusher with 2 x 200 mm rolls. Common applications include coal and diamond mining. Essa RC3000

Toothed roller crusher All industrial manufacturers DirectIndustry

toothed roller crusher SFH 200 -EPE stationary Contact Capacity: 40 kg/h 900 kg/h Operation The SFH crushers are equipped of removable hardened teeth and knifes

Mid-range rolls crushers tough on any material

The Essa Rolls Crusher range includes: Essa RC2000 Rolls Crusher compact and rapid standalone rolls crusher with 2 x 200 mm rolls. Common applications include coal and diamond mining. Essa RC3000

Toothed roller crusher All industrial manufacturers

The RC3000 is the larger of the two Essa model rolls crushers and can be configured Compare this product Remove from comparison tool. See the other products Essa Australia. toothed roller crusher MGB . stationary. Contact. toothed roller crusher. MGB . Capacity: 15 t/h 55 t/h toothed roller crusher. SFH 200 -EPE. Capacity: 40 kg/h

Reliable Toothed Roll Crusher Fote Machinery

So, the user finally chose Fote toothed roll crusher to replace the original ring hammer crusher. table: Results of discharging sieving test. discharging size (mm) productivity of ring hammer crusher(%) productivity of double

Sampling Sizers/Roll Crushers McLanahan

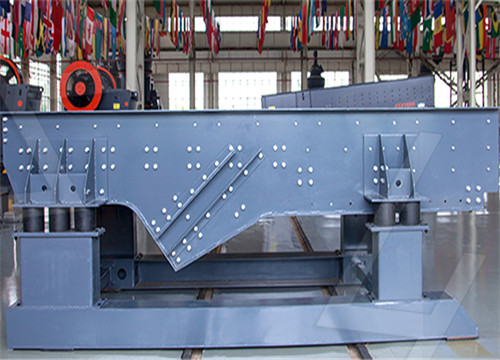

Material to be crushed is fed into the top of the machine, where it is crushed through two rotating roll assemblies and passed out through the bottom of the crusher. The crushed product size and gradation is based on the distance between the rolls and the tooth profile on the crusher rolls.

Toothed Roll Crusher For Coal Preparation Plant

The toothed roll crusher is suitable for crushing raw coal in coal mines, coal preparation plants and other industries (allowing less than 30% of coal gangue in raw coal). The crusher is also used to break other brittle

Roll Crusher With stable Performance Fote Machinery

Download Roll Crusher 1.61 MB Applied materials: coal, pebble, limestone, dolomite, granite, construction waste, pebbles, glass, cement clinker, basalt, iron ore, quartz stone, coal gangue, etc. Its advantages: high capacity,

Toothed/Double Roll Crusher Fote Machinery(FTM)

In 2017, Fote double toothed roll crushers were introduced to a Germany mining plant to be used in a pebble crushing line. This pebble production line has a capacity of 100TPH, input size of 50-200mm and output size below

Roll crusher.ppt

2015年10月18日Smooth Roll Crusher: 4. Toothed Roll Crusher: 6. * 10/18/201514ch42, 14ch24 6 WORKING MECHANISM: Rolls Crushers (High Pressure Grinding Rolls) consists of two parallel rotating rolls

Sizers McLanahan

The crushing rolls can be rotated either inward or outward at slow speed and high torque, which minimizes slippage and fines generation. Slow-speed Sizers are selected for the specific material and lump size to be crushed. Tooth profile selection allows the material to be grabbed and pulled into the crushing zone for maximum efficiency.

Mining Iron Ore Rollers Crushing Machine Price, Coal Double Toothed

Roll crusher is also called double roll crusher, double teeth roll crusher etc. The surface of roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine

Design and experimental research on the counter roll differential

Among them, during the operation of the counter roll, the maximum distance between the toothed rolls may be L a, Laboratory-scale validation of a dem model of a toothed double-roll crusher and numerical studies. Powder Technol., 356 (2019), pp. 60-72. View PDF View article Google Scholar. Lin et al., 2022.

Roll Crushers Top 2022 Models 911Metallurgist

Roll Crushers Top 2022 Models Roll Crushers 8″ Double Roll Crusher US$ 7,000 Roll Crusher US$ 12,000 8″ Laboratory Roll Crusher 10″ to 12″ Double Roll Crushers US$ 27,000 Roll Crusher for Sale The standard

Roll Crusher| Double Roller Crusher |DOVE

DOVE Roll Crushers are designed with compact structure, small space installation, Light weight, Convenient operation, and low maintenance. DOVE Tooth Roll Crushers are supplied in eight models with large crushing capacity of up to 300 metric Tons/Hour.; DOVE Tooth Roller Crushers are highly safe and reliable, they are configured with high quality

USA Double-roll crusher Google Patents

Y10T83/9319 — Toothed blade or tooth therefor. US06/044,285 1978-05-31 1979-05-31 Double-roll crusher Expired Lifetime USA (en) Roll Crusher for Crushing Hot Cement Clinker WOA1 (en) * 2007-07-31: 2009-02-05: Jeroen Maaren: System, method and apparatus for processing bone product

Reliable Toothed Roll Crusher Fote Machinery

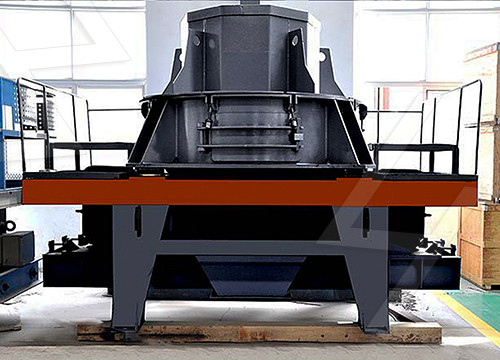

Double Toothed Roll Crusher Applied material: coal, pebble, perlite, limestone, dolomite, etc. Its outstanding features: high crushing capacity, hadraulic pressure used to adjust the distance between the rollers, and

Toothed roller crusher All industrial manufacturers

toothed roller crusher SFH 200 -EPE stationary Contact Capacity: 40 kg/h 900 kg/h Operation The SFH crushers are equipped of removable hardened teeth and knifes arranged on one or double-shaft. The assembly is drive by an angular and double global motor reducer for decrease the speed and increase impact crusher

Toothed Roll Crusher For Coal Preparation Plant

Toothed roll crusher is widely used in coal, metallurgy, mining, chemical industry, building materials, and other industries, and it is more suitable to crush coal in large coal preparation plant and process waste. Toothed

Roll Crusher With stable Performance Fote Machinery

Download Roll Crusher 1.61 MB Applied materials: coal, pebble, limestone, dolomite, granite, construction waste, pebbles, glass, cement clinker, basalt, iron ore, quartz stone, coal gangue, etc. Its advantages: high capacity,

Toothed/Double Roll Crusher Fote Machinery(FTM)

In 2017, Fote double toothed roll crushers were introduced to a Germany mining plant to be used in a pebble crushing line. This pebble production line has a capacity of 100TPH, input size of 50-200mm and output size below

Introduction of Toothed Roll Crusher Luoyang Dahua

2022年4月15日On April 15, 2022. Home News Introduction of Toothed Roll Crusher. Toothed roll crusher has a single or multiple motor that drive the belt wheels on the both side of crusher rotating the toothed roller in opposite direction. The material in line with the gap between the two toothed rollers falls automatically, and the material larger than the

Toothed Roll Crusher mpl Machinery

Toothed Roll Crusher Production capacity: 70–460 t/h Feeding granularity: 100–800 mm Dimensions: 2100×2450×2000–2500×4360×2400 mm Power: 74–320 kw Weight: 16100–40700 kg Material handling: coal, pebble,

Double RollTeethed Roll Crusher Mineral

2016年2月24日The range of the smooth-face rolls, for example, is from about 400 ft/min for the small 12-in. rolls, to 2000-2200 feet/minute for the heavy-duty 72″ machine. The single-roll crusher has a tip speed of 400

Roll crusher.ppt

2015年10月18日Smooth Roll Crusher: 4. Toothed Roll Crusher: 6. * 10/18/201514ch42, 14ch24 6 WORKING MECHANISM: Rolls Crushers (High Pressure Grinding Rolls) consists of two parallel rotating rolls

Mining Iron Ore Rollers Crushing Machine Price, Coal Double Toothed

Roll crusher is also called double roll crusher, double teeth roll crusher etc. The surface of roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine

Design and experimental research on the counter roll differential

Among them, during the operation of the counter roll, the maximum distance between the toothed rolls may be L a, Laboratory-scale validation of a dem model of a toothed double-roll crusher and numerical studies. Powder Technol., 356 (2019), pp. 60-72. View PDF View article Google Scholar. Lin et al., 2022.

Sizers McLanahan

The crushing rolls can be rotated either inward or outward at slow speed and high torque, which minimizes slippage and fines generation. Slow-speed Sizers are selected for the specific material and lump size to be crushed. Tooth profile selection allows the material to be grabbed and pulled into the crushing zone for maximum efficiency.

USA Double-roll crusher Google Patents

Y10T83/9319 — Toothed blade or tooth therefor. US06/044,285 1978-05-31 1979-05-31 Double-roll crusher Expired Lifetime USA (en) Roll Crusher for Crushing Hot Cement Clinker WOA1 (en) * 2007-07-31: 2009-02-05: Jeroen Maaren: System, method and apparatus for processing bone product