Copper Concentrator Technology

Escondida Copper, Gold and Silver Mine, Atacama Desert

2020年9月21日The copper production in FY2020 was increased by 4% to 1,185kt, supported by concentrator throughput of 371ktpd. The mine is expected to produce between 940kt and 1,030kt of copper for FY2021,

Leveraging an Innovative and Unique Particle Size Mining

The purpose of this stone is to: (1) explore why transformative technologies are slow to be adopted in the minerals processing industry, (2) provide a case study of how a copper

Copper Concentrate an overview ScienceDirect Topics

1 Introduction Copper smelting plants separate elemental copper from copper concentrates through multiple sulphide oxidizing stages. The considered smelting

Copper processing Roasting, smelting, and converting

Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and

Copper Refining: From Ore to Market

2022年2月22日In hydrometallurgy, copper concentrate undergoes refining via one of a few processes. The least common method is cementation, in which an acidic solution of

Copper Mining and Processing: Everything you Need to

Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production. Using today’s compact mining equipment, copper

COPPER Copper production TU Delft

Figure 2: Overview of a typical beneficiation process at a concentrator Sulfidic copper ores are too dilute for direct smelting. Smelting these materials would require too

TECHNOLOGY — IGNEO e-waste recycling

Our patented technology separates and recovers 98% of these precious metals, creating a highly sustainable copper concentrate. Meanwhile, our technology also mitigates any

Metso Outotec wins major order to deliver key process

2020年12月29日Metso Outotec has signed a contract for the delivery of key minerals processing technology to a new high-capacity copper concentrator in Russia. The customer and the contract value are not

BHP inaugurates a new copper concentrator in Spence which will

2022年5月13日BHP inaugurates a new copper concentrator in Spence which will allow the operation to be extended by 50 years 13 May 2022 The project supports BHP's intention to continue growing in Chile while strengthening its global copper portfolio. The new plant was built with more than 12 thousand workers and total investment reached US$2,460

Copper extraction Wikipedia

Copper smelting technology gave rise to the Copper Age, aka Chalcolithic Age, Copper concentrate is traded either via spot contracts or under long term contracts as an intermediate product in its own right. Often the smelter sells the copper metal itself on behalf of the miner. The miner is paid the price at the time that the smelter

Las Bambas Greenfield Copper Concentrator Bechtel

Las Bambas is a greenfield copper concentrator project located at 13,780 feet (4,200 meters) above sea level in the Peruvian Andes owned and operated by MMG, which has helped Peru further strengthen its position

Jameson Concentrator Glencore

The Jameson Concentrator helps you solve the conflict between higher performance expectations and lower quality of ore bodies. The Jameson Concentrator combines various configurations of Jameson Cell, modified and proven to process even larger volumes, and can add new generation small-footprint IsaMill™ technology where greater and precise

Bozshakol Copper Project Mining Technology

2016年6月23日Copper concentrate is gradually separated as the waste tailings undergo flotation, with molybdenum being separated at the end of the flotation process. The obtained copper concentrate is pumped into

Batu Hijau Copper-Gold Mine Mining Technology

2004年10月5日The concentrator circuit consists of two-train SAG and ball mills, followed by primary and scavenger flotation cells, vertical regrind mills and cleaning flotation cells to produce a copper-gold concentrate

Oyu Tolgio Gold and Copper Project, Mongolia

2019年8月16日In March 2010, the key mining equipment was purchased. It included the major components for the 100,000tpd phase one copper-gold concentrator. Production at Hugo North is expected to commence in

TECHNOLOGY — IGNEO e-waste recycling

Our patented technology separates and recovers 98% of these precious metals, creating a highly sustainable copper concentrate. Meanwhile, our technology also mitigates any of the harmful emissions associated with traditional precious metal reclamation too. Typical E-wASTE Composition.

Metso Outotec to deliver processing technology to

2020年12月30日Finnish mining technology firm Metso Outotec said on Tuesday it has won a large deal to delivery technology to a new copper concentrator in Russia with processing capacity of at least 80 million

Copper Concentrate Market Size and Growing Strategies 2023:

2023年3月7日The Copper Concentrate market report provides in-depth insights into the industry segments by type ( Pyrometallurgical, Hydrometallurgy ), applications (Electrical Industry, Mechanical...

Panama, Canadian Group Agree To Reopen Major Copper Mine

2 03/08/23 AT 11:45 AM EST. An aerial view of Cobre Panama mine is seen in Donoso, 120 kilometers west of Panama City in December 2022 AFP. Panama and Canadian giant First Quantum Minerals announced

Copper Processing Plant Prominer (Shanghai) Mining Technology Co.,Ltd.

I. Physical processing technology: II. Chemical processing technology: 1. Flotation process are widely used for copper extraction. The ore pulp slurry is pumped to flotation cells for extracting. The flotation cells are divided into several parts: roughing, concentration and scavenging (the exact numbers of stages for each part should be

Copper processing Roasting, smelting, and converting

Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractory-lined furnace of either the hearth or fluidized-bed type. As concentrate is fed

Sayona Mining restarts production at NAL operations in Canada

2 Credit: Sayona Mining. Sayona Mining has started spodumene concentrate production at its North American Lithium (NAL) operation in Quebec, Canada. The company expects the first spodumene shipment from the mine will take place in July 2023, with four shipments planned for the first half of 2024. During this period, the NAL operation is

BHP inaugurates a new copper concentrator in Spence which will

2022年5月13日BHP inaugurates a new copper concentrator in Spence which will allow the operation to be extended by 50 years 13 May 2022 The project supports BHP's intention to continue growing in Chile while strengthening its global copper portfolio. The new plant was built with more than 12 thousand workers and total investment reached US$2,460

Copper extraction Wikipedia

Copper smelting technology gave rise to the Copper Age, aka Chalcolithic Age, Copper concentrate is traded either via spot contracts or under long term contracts as an intermediate product in its own right. Often the smelter sells the copper metal itself on behalf of the miner. The miner is paid the price at the time that the smelter

Jameson Concentrator Glencore

The Jameson Concentrator has highly customisable flowsheets deployable by EPCMs to suit any of their client requirements. The Jameson Concentrator gives you or your client Up to 60% footprint reduction for significant CAPEX savings From 30–60% of the energy of a conventional flotation circuit

Copper processing Roasting, smelting, and

Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and

Oyu Tolgio Gold and Copper Project, Mongolia

2019年8月16日It included the major components for the 100,000tpd phase one copper-gold concentrator. Production at Hugo North is expected to commence in 2021, with average production exceeding 550,000t of

TECHNOLOGY — IGNEO e-waste recycling

Our patented technology separates and recovers 98% of these precious metals, creating a highly sustainable copper concentrate. Meanwhile, our technology also mitigates any of the harmful emissions associated with traditional precious metal reclamation too. Typical E-wASTE Composition.

Metso Outotec to deliver processing technology to

2020年12月30日Metso Outotec has signed a contract for the delivery of key minerals processing technology to a new high-capacity copper concentrator in Russia. The customer and the contract value are not

Copper Concentrate Market Size and Growing Strategies 2023:

2023年3月7日The Copper Concentrate market report provides in-depth insights into the industry segments by type ( Pyrometallurgical, Hydrometallurgy ), applications (Electrical Industry, Mechanical...

Copper Processing Plant Prominer (Shanghai)

General processing technologies for copper ore are summarized as below: I. Physical processing technology: CrushingGrinding Solution Flotation Process II. Chemical processing technology: Leaching 1. Flotation

Panama, Canadian Group Agree To Reopen Major Copper Mine

2 03/08/23 AT 11:45 AM EST. An aerial view of Cobre Panama mine is seen in Donoso, 120 kilometers west of Panama City in December 2022 AFP. Panama and Canadian giant First Quantum Minerals announced

Sayona Mining restarts production at NAL operations in Canada

2 Credit: Sayona Mining. Sayona Mining has started spodumene concentrate production at its North American Lithium (NAL) operation in Quebec, Canada. The company expects the first spodumene shipment from the mine will take place in July 2023, with four shipments planned for the first half of 2024. During this period, the NAL operation is

2021 News Ivanhoe Mines Ltd.

2021年11月18日Approximately one-half of the world’s primary copper currently is produced using flash, direct-to-blister smelting technology. Metso Outotec recently signed a major engineering and technology contract for the delivery of a landmark copper smelter complex to be built in Gresik, East Java, Indonesia.

Continuing a strong partnership: receives fourth copper

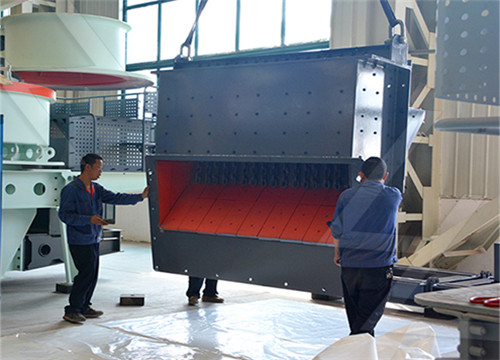

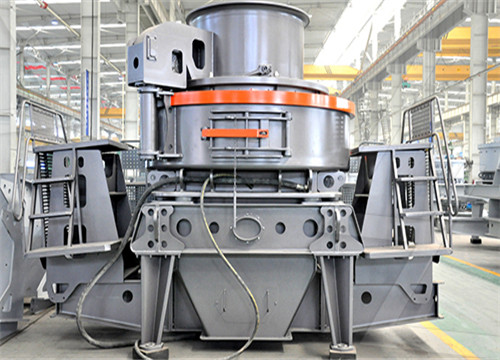

2018年2月22日Scope: new copper concentrator with the latest environmental control systems to mitigate environmental impact and technology for the highest levels of energy efficiency and maintainability and productivity; Equipment: SAG and ball mills, gyratory crusher, pebble crusher, primary and regrind cyclones, flotation cells, scavenger cells

Materials Free Full-Text The Wear on Roller Press Rollers Made

This stone defines the wear process of rollers made of 20Cr4. Rollers with a diameter of 1000 mm were installed in a roller press used for the production of drop-shaped briquettes and the copper concentrate was briquetted for 1100 h. Three-dimensional (3D) geometry analysis, metallographic analysis, macroscopy, scanning electron microscopy, as well as