Parts For Gulin Gyratory Crushers

Crusher spare parts Metso Outotec

Reliant crusher spare parts. Reliant crusher spares are the ideal combination of value, quality and function. Offered to our customers who need a cost-sensitive alternative to our premium spares but want the

Primary Gyratory Parts Gyratory Crusher Parts CMS

2018年9月3日The CMS Cepcor® product range of precision machined replacement parts to suit primary gyratory crushers includes complete

Gyratory Crusher Parts Wear Parts For Industry Qiming

The gyratory crusher operates by moving the central shaft and creating a conical crushing motion that compresses the rock against the concave surface. The main parts of a gyratory crusher include: Spider

Primary gyratory crusher parts Metso Outotec

Common wear parts Mantles Concave segments Bottom shell side liners Spider cap Arm liners Rim liners Check the video Watch the video to see how we can help you to get the maximum potential out of your crusher

Gyratory Crusher Wear Parts Columbia Steel Cast

Real world solutions. For over four decades, Columbia Steel has applied the same engineering problem-solving to gyratory crushers which has

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日Essentially, the gyratory crusher consists of a heavy cast-iron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone

Gyratory Crusher Parts Casteel Foundry

The Gyratory Cone Crusher is one of the main types of primary crushers in a mine ore processing or rock crushing plant, is similar in basic concept to a jaw crusher, consisting

Gyratory Crusher Components Mineral Processing

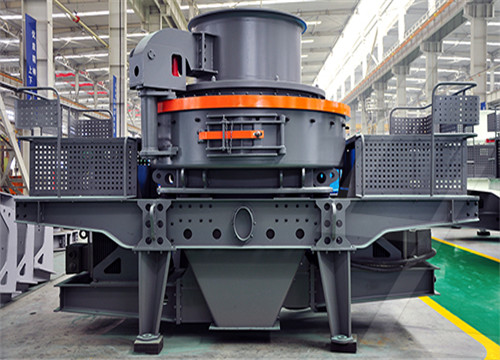

2015年7月18日Gyratory Crusher Components The Gyratory Crusher is made up of six main components,Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. The base is

Gyratory Crusher Parts Mayang Crusher Parts

Gyratory Crusher Parts. Mining Industry Concave, Mantle, Bowl liner, Spider shield, Spider Cap. For over 35 decades, Mayang has applied the same engineering problem-solving to

Gyratory Crusher Wear Parts For Popular Brands By MGS

We offer high-quality replacement gyratory crusher wear parts, such as liners, mantles, spider caps, and spider arms. Common Alias: Gyratory wear parts, gyratory concave, gyratory mantle, cone liner, bowl liners,

Primary Gyratory Parts Gyratory Crusher Parts

The CMS Cepcor® product range of precision machined replacement parts to suit primary gyratory crushers includes complete main shaft assemblies, main shafts, cores, spider assemblies, spider bushings, spider seals, top

Primary gyratory crusher parts Metso Outotec

Common wear parts Mantles Concave segments Bottom shell side liners Spider cap Arm liners Rim liners Check the video Watch the video to see how we can help you to get the maximum potential out of your crusher

Crusher Spares Crusher Parts CMS Cepcor

If you need high-quality replacement crusher parts and spares at a great price then contact CMS Cepcor® today. All parts warrantied and traceable. +1-877-CEPCOR1 (+1-877-) Gyratory Parts. Cone Parts.

Gyratory Crusher Parts Wear Parts For Industry

It consists of a central upright shaft that is surrounded by a concave surface called the “bowl,” which is lined with manganese steel. The gyratory crusher operates by moving the central shaft and creating a conical

Crusher Wear Parts for Popular Crushers Columbia

Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and

Gyratory Crusher Wear Parts Columbia Steel Cast

Real world solutions. For over four decades, Columbia Steel has applied the same engineering problem-solving to gyratory crushers which has proven so effective on cone crushers. We went into the field and studied the

Gyratory Crusher Components Mineral Processing

2015年7月18日Gyratory Crusher Components The Gyratory Crusher is made up of six main components,Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. The base is

Heavy duty, maintenance-friendly Gyratory Crusher

EXCEL™ cone crusher parts for Sandvik® Hydrocone™ and Superior™ The Gyratory Crusher “NT” incorporates all of the TC’s heavy-duty design features (Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components) and focuses on coupling these historical

Gyratory Crusher (TS) for harsh environments

Gyratory Crusher Top Service — High power, reliability and less maintenance. The Gyratory Crusher TS design allows for a more cost effective and flexible layout of your crushing station. It features multiple

Metso SUPERIOR® gyratory crushers Metso

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine Metso’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy

What Type of Crusher Is Best for Primary Crushing?

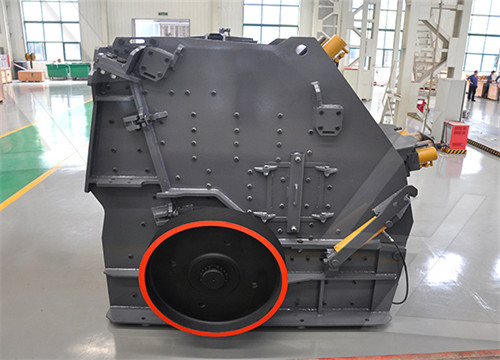

2021年3月25日Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite,

Cone Crusher Explained saVRee

Gyratory Crusher Operation Crushing action is produced by the oscillation or throw (openingclosing) between the moving mantle liner, mounted on the cone, and the stationary concave liners mounted within the upper casing of the crusher. The mantle and concaves form the working surfaces of the crusher, as this is where the crushing action

Tips for Crusher Maintenance Thomasnet

2018年11月28日The force exerted in the crushing chamber is generated and maintained by a flywheel moving the swing jaw, while the stationary jaw provides the resistance. Between the two surfaces, heavy materials such as stone and ore are broken into smaller pieces. Gyratory Crushers

Types of Crushers: What You Need to Know Machinery Partner

The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw crushers saw a resurgence in popularity. The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries.

Primary Gyratory Parts Gyratory Crusher Parts

The CMS Cepcor® product range of precision machined replacement parts to suit primary gyratory crushers includes complete main shaft assemblies, main shafts, cores, spider assemblies, spider bushings, spider seals, top

Primary gyratory crusher parts Metso Outotec

Common wear parts Mantles Concave segments Bottom shell side liners Spider cap Arm liners Rim liners Check the video Watch the video to see how we can help you to get the maximum potential out of your crusher

Crusher Spares Crusher Parts CMS Cepcor

If you need high-quality replacement crusher parts and spares at a great price then contact CMS Cepcor® today. All parts warrantied and traceable. +1-877-CEPCOR1 (+1-877-) Gyratory Parts. Cone Parts.

Gyratory Crusher Parts Wear Parts For Industry

It consists of a central upright shaft that is surrounded by a concave surface called the “bowl,” which is lined with manganese steel. The gyratory crusher operates by moving the central shaft and creating a conical

Crusher Wear Parts for Popular Crushers Columbia

Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and

Gyratory Crusher Wear Parts Columbia Steel Cast

Real world solutions. For over four decades, Columbia Steel has applied the same engineering problem-solving to gyratory crushers which has proven so effective on cone crushers. We went into the field and studied the

Gyratory Crusher Components Mineral Processing

2015年7月18日Gyratory Crusher Components The Gyratory Crusher is made up of six main components,Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. The base is

Parts for crushers Metso Outotec

Metso Outotec has created new premium parts offering for 3rd party crushers called the Contender™ Series. These high-performing parts fit also for some cone crusher and gyratory crusher models.

Heavy duty, maintenance-friendly Gyratory Crusher

EXCEL™ cone crusher parts for Sandvik® Hydrocone™ and Superior™ The Gyratory Crusher “NT” incorporates all of the TC’s heavy-duty design features (Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components) and focuses on coupling these historical

Gyratory Crushers Dorr-Oliver Eimco PDF

• Specialty Tools • Concave InstallationRemoval Tool • Main Shaft Servicing Stand • Dump Pocket Access Tools • Crusher Maintenance Carts • Operations and Maintenance Services • Installation Services •

Symons and Gyradisc Compression Crusher parts

Our cone crusher spare parts are improved over OEM standards, allowing for longer wear life and ease of installation. Gyratory crushers. EXCEL™ High Performance Spare Parts for Gyratory Crushers. English. PDF

ROCK PROCESSING EQUIPMENT AND SOLUTIONS — SRP

Our comprehensive range of cutting-edge equipment, tools, parts, service and solutions for processing rock and minerals are designed to increase your productivity and boost your bottom line. primary gyratory crushers are ideal for tackling large boulders with a large feed opening and a grooved mantle, an optimized nip angle, and

Metso SUPERIOR® gyratory crushers Metso Automation PDF

SUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 High-strength shell design,

Types of Crushers: What You Need to Know Machinery Partner

The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. The ore is discharged through the smaller bottom output hole of the cone. While the cone does not move, an interior crushing movement is created by a revolving shaft on a vertical rod.