Working Of Bowl Mill

Raymond® Bowl Mill designed and built for flexibility Schenck

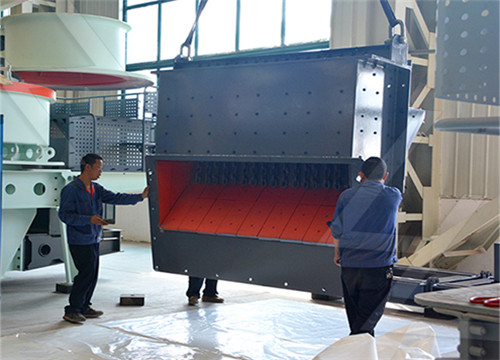

Each bowl mill system is designed to achieve the best solution for the processing application. The mill, feeder, classifier, fan, cyclone, dust collector and other system components are selected to meet the requirements and characteristics of the material

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

2021年8月5日In bowl mill pulveriser raw coal coming from feeder gets ground between the grinding rolls and bull ring segments installed on the revolving Bowl. Bowl is made to

Principle of operation bowl mill SlideShare

根据热度为您推荐•反馈

Bowl Mill Pulverizer YouTube

2019年5月7日17K views 3 years ago A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to

Pulverizers 101: Part I POWER Magazine

Pulverizer RecoveryA Four-Step PlanMore to ComeBlueprinting a pulverizer isn’t rocket science, but it does require close attention to the details. Here is our four-step plan to restore and improve performance of your pulverizer, regardless of its age. Step 1. Ensure that the grinding elements are in good condition. Make sure that the grinding surface profiles are optimum. That means using the o...

Bowl mill 3D view with live working procedure. Tharmal

2019年10月31日Bowl mill 3D view with live working procedure. Tharmal power plant Power Creation 1.34K subscribers Subscribe 305 Share Save 13K views 3 years ago I

Coal mill pulverizer in thermal power plants SlideShare

2012年11月17日14. 9.Tube Mill 15. 10.Bowl Mill Bowl mills are employed to pulverize the pre-crushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The mill

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can -and are- used for other purposes.. The 3D model in the saVRee

FeaturesWorking of Bowl Mills PDF Energy

高达$3返现with the Bull Rings, which is fitted on to the Bowl and mill motor drives the bowl through gear box. 1. BOWL Made of carbon steel and overlaid with Bull Ring, which is

The 6 Best Food Mills in 2023 The Spruce Eats

2022年9月28日It’s built for smooth and easy turning to put less pressure on your hand and arm as you mill through pounds of produce. The handle and knob are covered in grippy no-stick silicone. The mill includes

Raymond® Bowl Mill designed and built for flexibility Schenck

Each bowl mill system is designed to achieve the best solution for the processing application. The mill, feeder, classifier, fan, cyclone, dust collector and other system components are selected to meet the requirements and characteristics of the material processed. Bowl mill system

Pulverizer Wikipedia

The ball and tube mills are low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball

Coal Pulverizer Power Plant Pall Corporation

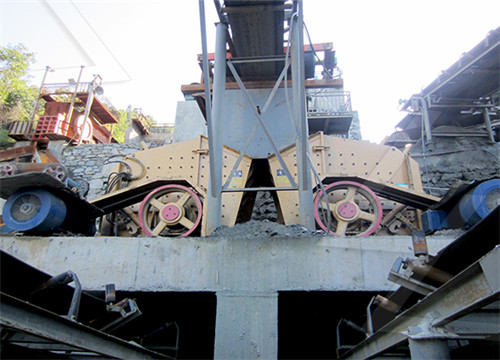

Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise most coal pulverizers currently in service at pulverized coal power plants. The grinding rolls are stationary in this design, while a worm gear drive rotates the ring

Improving Coal Pulverizer Performance and Reliability

Ring-Roll Mill the rolls may rotate while the ring is stationary). Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise the majority of coal pulverizers currently in service at power generating facilities. Figure 3 shows a cut-away of a Ring-Roll type coal pulverizer. In this design the grinding rolls are stationary, while the ring (or bowl,

Vertical Grinding Mill (Coal Pulverizer) Explained

Regulating the amount of gas that passes through the nozzle ring also regulates the amount of pulverized coal that is delivered to the furnace. Oversized pulverized coal impacts with the rotating classifier and drops

How it Works: Crushers, Grinding Mills and Pulverizers

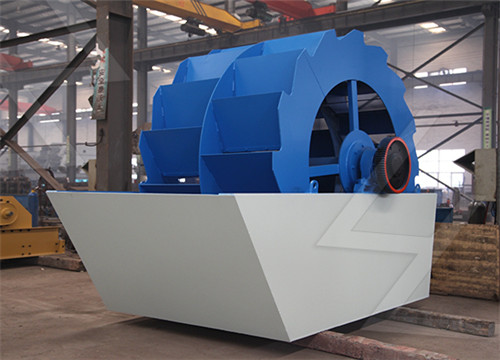

2017年6月2日Ball mills use a tumbling process with stone or metal balls as the grinding materials to reduce the coarse material by means of impact and friction. Ball mills typically use water or other liquid and additives to

FeaturesWorking of Bowl Mills PDF Energy Technology

3. BOWL HUB Connect Planetary Gearbox (Mill Drive) and Bowl. During pulverization process Bowl Hub will transfer Torque from mill drive to Bowl. Satendra Gangwar Assistant Engineer BMD-II, ‘D’TPS, Anpara BOWL HUB 4. SKIRT Protect the flow of coal and hot air towards mill drive and work as drive scraper. 5. LABYRINTH SEAL ASSEMBLY

Coal Hang-up in Bowl Mill Operations Bright Hub

2009年9月11日Bowl mills are used for pulverizing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the

Ball Mill SlideShare

2015年11月30日Principle of operation bowl mill Devidutta Panda WORKING: The material to be grind is fed at angle of 60 degree into the crushing zone and the product is discharged at 30 degree. As the shell

How does a coal mill in a thermal power plant work? Quora

Bowl mills are one type of grinding mill used in a coal-fired thermal power plant. Raw coal fed into the mills gets converted into pulverised coal and carried to the burners by primary air. Secondary air and sometimes tertiary air is admitted also to

Vertical Roller Mills

Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition monitoring services enable you to adopt a proactive maintenance

Fluid energy mill Pharmaguideline

Ball mills, sometimes referred to as pebble mills or tumbling mills, are milling machines that take the form of cylindrical vessels containing balls mounted on a metallic frame that can revolve around its longitudinal axis. Depending on the feed and mill size, balls with varying diameters occupy 30 50 % of the mill volume.

From Novice to Master Metal Lathe Projects Summit

A little different technique is required for these; you’ll either need to partly grind out the center of each piece, or spin and form the metal into the bowl or cup, finally finishing the outside. The same method is used to create cups, fancier goblets, or large and small bowls, giving a number of applications.

Improving Coal Pulverizer Performance and Reliability

Ring-Roll Mill the rolls may rotate while the ring is stationary). Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise the majority of coal pulverizers currently in service at power generating facilities. Figure 3 shows a cut-away of a Ring-Roll type coal pulverizer. In this design the grinding rolls are stationary, while the ring (or bowl,

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Ball mills use a tumbling process with stone or metal balls as the grinding materials to reduce the coarse material by means of impact and friction. Ball mills typically use water or other liquid and additives to

Coal Hang-up in Bowl Mill Operations Bright Hub

2009年9月11日Bowl mills are used for pulverizing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the

FeaturesWorking of Bowl Mills PDF Energy Technology

3. BOWL HUB Connect Planetary Gearbox (Mill Drive) and Bowl. During pulverization process Bowl Hub will transfer Torque from mill drive to Bowl. Satendra Gangwar Assistant Engineer BMD-II, ‘D’TPS, Anpara BOWL HUB 4. SKIRT Protect the flow of coal and hot air towards mill drive and work as drive scraper. 5. LABYRINTH SEAL ASSEMBLY

Ball Mill SlideShare

2015年11月30日Principle of operation bowl mill Devidutta Panda WORKING: The material to be grind is fed at angle of 60 degree into the crushing zone and the product is discharged at 30 degree. As the shell

Vertical Roller Mills

Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition monitoring services enable you to adopt a proactive maintenance

From Novice to Master Metal Lathe Projects Summit

A little different technique is required for these; you’ll either need to partly grind out the center of each piece, or spin and form the metal into the bowl or cup, finally finishing the outside. The same method is used to create cups, fancier goblets, or large and small bowls, giving a number of applications.

sbm/sbm construction amp amp working of bowl mill.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Six Finishes for Woodturners Woodcraft Supply

2012年12月3日Best Uses: Use this finish on salad bowls, platters, salt and pepper mills, and other utility items needing a durable finish. Downside: Longer drying time means that you need to wait a bit to apply multiple

Fluid energy mill Pharmaguideline

Ball mills, sometimes referred to as pebble mills or tumbling mills, are milling machines that take the form of cylindrical vessels containing balls mounted on a metallic frame that can revolve around its longitudinal axis. Depending on the feed and mill size, balls with varying diameters occupy 30 50 % of the mill volume.

High energy ball milling process for nanomaterial

The turn disc rotates in one direction while the bowls rotate in the opposite direction. The centrifugal forces, created by the rotation of the bowl around its own axis together with the rotation of the turn disc, are applied to the

AJ's Favorites — Chef AJ

Holland Bowl Mill manufactures en bowls, utensils and many other en products all made in USA. They always work with the most recent harvest year, and mill the product themselves, limiting shelf time by as much as a year compared to grocery store spices. I like that they both follow a plant-based diet, so their blends perfectly

Persentasi Alat Industri Kimia (Size Reduction) SlideShare

2019年3月18日Grinder Rolling-compression mills Bowl Mill Prinsip Kerja : Bowl Mill atau sering disebut juga Pulverisers adalah salah satu alat pembantu utama yang berada di pembangkit listrik dari Batu Bara. Umpan masuk dari feed hopper kedalam mangkok yang berputar (mangkok dilapisi dengan bahan dengan kekerasan > kekerasan bahan yang

Planetary Ball Mill PM 100 RETSCH highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short