Coal Mill Ball Producer

Coal Pulverizer Power Plant Pall Corporation

The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the

Coal Mill in Cement Plant Vertical Roller MillAir

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires

进一步探索

Coal Mills in Thermal Power Plant PDF Mill (Grinding) (PDF) Control for pulverized fuel coal mill ResearchGate根据热度为您推荐•反馈

Global Steel Ball Coal Mill Market Production Capacity

2023年2月13日Global Steel Ball Coal Mill Market Production Capacity Estimates and Forecasts to 2028 Industry Size, Current Trend, Competition, Growth, Product Price,

Coal Ball Mill Grinding for Different Kinds of Pulverized

Coal Ball Mill Feeding size: ≤25mm Capacity: 5-20t/h Functional advantages: Less failure and reliable operation Applications: It is mainly

Vertical Coal Mill ball mills supplier

Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plant.

Coal Ball Mill gwmcn

11 行Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is mainly composed of feeding device, principal axis, rotating part,

Coal Mill Great Wall

1. less investment, more energy-saving than similar products. 2. easy to operate, safe to use, stable and reliable performance. 3. running stably and continually, the production capacity is great. Compared with ball mills

Coal Mill an overview ScienceDirect Topics

L. Juniper, G. Schumacher, in The Coal Handbook: Towards Cleaner Production: Coal Utilisation, 2013 13.2.2 Milling processes Most milling operations focus on four

A Modeling and Optimizing Method for Electricity Current Hindawi

2022年2月9日Coal mill is an important auxiliary device for coal-fired boilers since it directly influences the boiler combustion. The coal mill grinds the raw coal to a certain fineness, and then, the coal powder is carried to the burners by first air of boiler combustion.

Flexible milling and grinding solutions that last

The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality, simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills. Our ATOX® coal mill

Coal Mill Great Wall

Coal ball mill is a machine that crushes and grinds the coal briquette into pulverized coal It is important auxiliary equipment of pulverized coal furnace During the coal grinding process, the coal is crushed and its superficial

Coal Ball Mill Grinding for Different Kinds of

Coal Ball Mill. Feeding size: ≤25mm. Capacity: 5-20t/h. Functional advantages: Less failure and reliable operation. Applications: It is mainly used for grinding coal of various hardnesses, and is also suitable for

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, coal, pigments, and feldspar for pottery. Grinding can be carried out wet or dry, but the former is performed at low

Coal Mills Steam Forum

include Ball Tube Mills (BTM), MPS mills and Atrita Since the first application using an MPS mill to process pulverized coal in Germany in the mid 1960s, there have been over 2,000 different MPS mill installations operating in coal-fired power plants worldwide. As one of the most popular coal pulverizers in the utility industry, the MPS

Coal Ball Mill gwmcn

Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is mainly composed of feeding device, principal axis, rotating part, transmission part, discharging part, high-pressure starting device and lubrication system. Riverside Group Co.,LTD 3000t/d production line Φ3.4×6+3m coal mill. Coal ball mill is

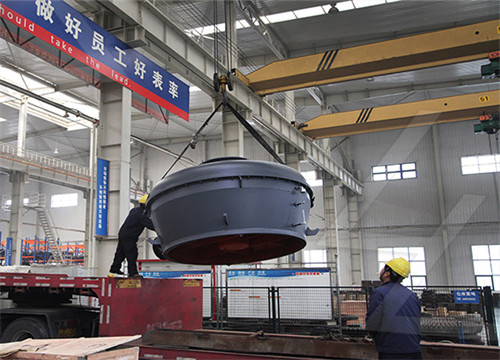

Coal Ball Mill CHAENG

Steel ball coal mill is one of the auxiliary machines of the thermal power station and an important equipment for the pulverized coal preparation system. This series of coal mills are mainly used to grind coals of various hardness. Application: Power plants, cement plants, lime plants and other coal grinding enterprises Capacity: 12-38 t/h

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

2021年8月5日The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter.

20tph Coal Ball Mill for Clean Coal Powder

MFB3090 coal ball mill, as the main equipment of 300,000 tons high-efficiency clean coal powder production line, is improved by our company’s technical personnel on the traditional air-swept coal mill. Its output has

CHAENG CementMining Equipment Supplier

Complete Set Of Cement Production Line Provided By XinXiang Great Wall (CHAENG),Equipments For Cement,Mining. Provide GGBFS Plant Mining Mill Slag Mill Vertical Roller Mill Cement Tube Mill Ball Mill Grinding Equipments Cement Rotary Kiln| GRMS Slag Vertical Mill, GRMK Vertical Cement Mill, and GRMC Vertical Coal Mill

Ball Mills Industry Grinder for Mineral Processing

JXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 18.5-800KW. During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand

Coal Ball Mill CHAENG

The coal is grinded into pulverized coal in the coal ball mill mainly by means of three ways: press, strike and grind. Among them, the first way is the most energy-saving, and the last one most energy-consuming. Cement Ball Mill; Rotary Kiln; Cement Production Line; Get a Quote. Contact Us. E-mail: [email protected]. Tel.:+

Flexible milling and grinding solutions that last

Carefully crafted to meet your milling and grinding needs, our robust and well-designed solutions are highly adaptable for a range of feed materials. With compact layouts, long-lasting wear parts and easy access for

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, coal, pigments, and feldspar for pottery. Grinding can be carried out wet or dry, but the former is performed at low

Coal Ball Mill Grinding for Different Kinds of

Coal Ball Mill Feeding size: ≤25mm Capacity: 5-20t/h Functional advantages: Less failure and reliable operation Applications: It is mainly used for grinding coal of various hardnesses, and is also suitable for

Ball Mills Industry Grinder for Mineral Processing

JXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 18.5-800KW. During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand

Coal Ball Mill gwmcn

Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is mainly composed of feeding device, principal axis, rotating part, transmission part, discharging part, high-pressure starting device and lubrication system. Riverside Group Co.,LTD 3000t/d production line Φ3.4×6+3m coal mill. Coal ball mill is

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

2021年8月5日The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter.

20tph Coal Ball Mill for Clean Coal Powder

Production capacity: Annual output of 300,000 tons Processed material: Soft coal Input size: ≤25mm Equipment: 5 sets of 20tph coal ball mill Auxiliary equipment: Desulfurization, denitrification, dust removal and

CHAENG CementMining Equipment Supplier

Ball Mill High yield, durable, smooth running, reliable performance, and good wear resistance. Can grind Cement, slag, steel slag, nickel slag, coal and various mineral ore Rotary Kiln CHAENG has rich experience in the production of large-scale cementlime rotary kiln, and can provide 300-3000 t/d rotary kiln equipment. Steel Casting

A Modeling and Optimizing Method for Electricity Current Hindawi

2022年2月9日Coal mill is an important auxiliary device for coal-fired boilers since it directly influences the boiler combustion. The coal mill grinds the raw coal to a certain fineness, and then, the coal powder is carried to the burners by first air of boiler combustion.

11.25 Clay Processing US EPA

The shredded material then is either dried or ground in a hammer mill. Material exiting the hammer mill is mixed with water and bulk loaded as a slurry for shipping. Figure 11.25-3 depicts the process flow for ball clay processing. Indirect rotary or vibrating grate dryers are used to dry ball clay. Combustion gases from the

Coal Pulverizer Maintenance Improves Boiler Combustion

2015年12月1日We have found that targeting an A/F ratio around 1.8 lb of air per lb of fuel is best. For some pulverizer types, such as ball tube mills and high-speed attrition mills, often a 1.6 A/F ratio is

Coal Mill Coal Grinding Mill Producer SINOMALY

Coal Grinding Mill. SINOMALY coal grinding mills are used in coal powder production lines with an output range of 8-83t/d. We have decades of experience in the production of coal mills that are designed to handle a wide variety of bituminous coal and anthracite with a maximum capacity of 85 T/h. The main components of this coal grinding mill

Coal Ball Mill CHAENG

The coal is grinded into pulverized coal in the coal ball mill mainly by means of three ways: press, strike and grind. Among them, the first way is the most energy-saving, and the last one most energy-consuming. Cement Ball Mill; Rotary Kiln; Cement Production Line; Get a Quote. Contact Us. E-mail: [email protected]. Tel.:+