Raymond Roller Mills For Cryogenics

Raymond® Fine Grinding Roller Mill Schenck Process

The Raymond® fine grinding roller mill is an air-swept vertical pendulum mill with integral classification. A vertical shaft rotates an assembly of grinding journals /rolls inside the grinding zone. As the unit turns,

Cryogenic mill, Cryogenic pulverizer All industrial

cryogenic pulverizer. vertical for compact. Final grain size: 500 µm. Output: 250 kg/h 450 kg/h. Machine length: 2,400 mm. The Reduction Engineering pulverizer

进一步探索

Cryogenic Pulverizer WANROOETECHTHE NEW CRYO MILL Efficient Grinding at -196 °C Ver根据热度为您推荐•反馈

Cryo Milling Material Milling AVEKA

Cryogenic milling, or cryo-milling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process. AVEKA ‘s

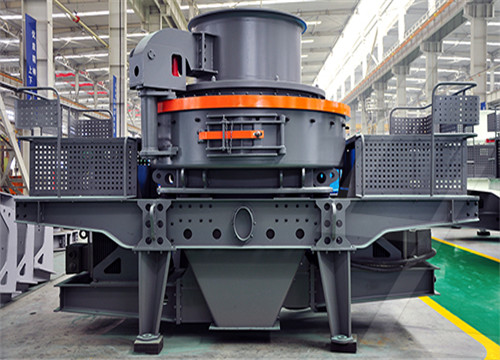

Raymond Roller Mills Fote Machinery(FTM)

Raymond mill is also called Raymond roller mill or Raymond grinding mill, which is one of the most widely used grinding equipment. As one

Used Raymond Roller Mills for sale. Raymond equipmentmore

Manufacturer: Raymond. 35196 Used- C.E. Raymond #73412 Roller Mill. Directly driven by a 350 hp, 3/60/4160V, 585 rpm motor. Unit is equipped with a gear and intermediate

Raymond Roller Mill Parts IndustrialMining Services

The Raymond roller mill, also known as the Raymond pulverizer is used in a variety of industries, including highway construction, the mining industry, the chemical industry, the construction industry and the metallurgy field.

Raymond Roller Mill Raymond Grinding Mill For Getting

The Raymond roller mill is used to grind various of materials for getting coarse powder. Its applicable materials include dolomite, limestone, barite, talc, diabase, quartz, gypsum, bentonite, etc. In general, these materials

Alstom Introduces Its Largest High Capacity Roller Mill

2012年4月16日Raymond120.jpg. Warrenville, Illinois Alstom today introduced its new Raymond® 120” Roller Mill System designed to dry, pulverize, classify and deliver various types of materials with feed sizes

High-efficient Raymond Mill Fote Machinery

5. Features of Ftmmachinery Raymond mill. 1. Large output and high grinding efficiency. Outputs of 8 to176 tons per shift (8 hours). The finished powder is uniform in fineness, and the passing rate is as high as 99%. 2.

Dry milling machines Schenck Process

Our largest and strongest products include dry and wet milling machines that grind hard, abrasive materials for applications like mineral processing, cement plants, and power generation. They are are characterized by their excellent wear life, high availability and easy maintenance. At the other end of the scale we have ultra fine mills that

Raymond® Fine Grinding Roller Mill Schenck Process

The Raymond® fine grinding roller mill is an air-swept vertical pendulum mill with integral classification. A vertical shaft rotates an assembly of grinding journals /rolls inside the grinding zone. As the unit turns,

B&W Parts, Services and Programs for CE-Type Pulverizers / Mills

B&W supports pulverizers/mills manufactured by CE and others, including: CE/Raymond deep bowl mills; CE shallow bowl mills; Schenck Raymond roller mills; Mill services from our regional centers of excellence. Journal rebuilds and exchanges assemblies rebuilt to original OEM specs; thorough inspection reports; standard parts in-stock for quick

Cryo Milling Material Milling AVEKA

What is Cryogenic Milling? Cryogenic milling, or cryo-milling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process. AVEKA ‘s cryogenic hammer mills can typically

Raymond Mill History, Working PrincipleApplications

The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation. Materials: Barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorspar, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, etc.

High-efficient Raymond Mill Fote Machinery

5. Features of Ftmmachinery Raymond mill. 1. Large output and high grinding efficiency. Outputs of 8 to176 tons per shift (8 hours). The finished powder is uniform in fineness, and the passing rate is as high as 99%. 2.

Raymond Roller Mill Parts-Ultimate Guide Fote

2023年2月15日Raymond grinding roller materials usually are made of alloy steel, alloy carbon steel, ZG65Mn manganese alloy steel, ZGMn13 high manganese alloy steel. Among them, alloy steel and high-quality

Raymond Roller Mill Parts IndustrialMining

The Raymond roller mill, also known as the Raymond pulverizer is used in a variety of industries, including highway construction, the mining industry, the chemical industry, the construction industry and the metallurgy field.

Roll Mills for PlasticRubber Industries Perry Videx

Pellet Mills (9) Pelletizer Pan (3) Raymond Roller Mills (1) Rietz Type Disintegrator Mills (6) Roll Mills 2, 3 or More Rolls (14) Cryogenic Tanks (13) Freezer (2) Miscellaneous Lined Tanks (47) Used one roller Mill manufactured by Buzuluk type MOA 2. Roller length is 1000 mm (39″) X diameter 400 mm (14″).

Industrial Roller Mills Raymond Equipment for Sale

Industrial Roller Mills Raymond Equipment for Sale Wabash Power. 847-541-5600 Quote 0. 24/7 Emergency Service 847-541-5600. Canadian Customers.

Used Paper Machines and Components For Sale Perry Videx

As experienced used equipment dealers, our inventory of stone machines and stone machine accessory parts is separated into categories to make your search of our stock easier. Please select the category that best matches your needs. Don’t see what you need? Contact Tom Royston at 609-267-1600 or via e-mail at troyston@perryvidex. Save

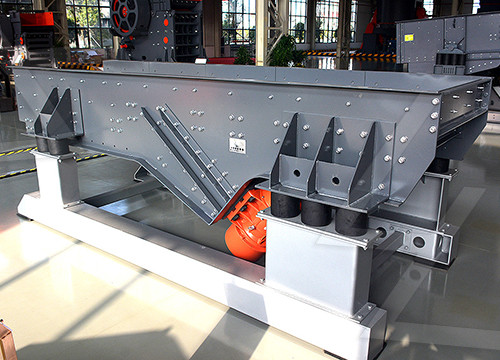

Roller mills: Precisely reducing particle size with greater

The roller mill’s ability to reduce materials to a uniform particle size provides more control of product characteristics and minimizes waste, as shown in Figure 1. The mill’s controlled reduction action requires less energy than other grinding methods, improving production effi-ciency and saving energy dollars. Roller mill components and

How to Maintain My Raymond Mill to Improve the Efficiency?

2019年9月24日This type of Raymond roller mill is commonly applicable to over 280 kinds of non-combustible and non-explosive materials with Mohs hardness of not more than 9.3 and a humidity of less than 6%, such as barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, limestone, activated clay, activated carbon and bentonite

Raymond Mills Raymond Roller Mill Grinding Mill AGICO

Raymond mill is also called Raymond roller mill. It is a new type of high-fineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball mill.This kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc. Under normal conditions, these materials’ Mohs

Dry milling machines Schenck Process

Our largest and strongest products include dry and wet milling machines that grind hard, abrasive materials for applications like mineral processing, cement plants, and power generation. They are are characterized by their excellent

Raymond® Bowl Mill designed and built for flexibility Schenck

Raymond® Bowl Mills provide the following performance features: Wide range of capacities base capacities from 8 to 150 tph. Easily adjustable fineness externally adjustable classifier permits selection of fineness from 70% to

B&W Parts, Services and Programs for CE-Type Pulverizers / Mills

B&W supports pulverizers/mills manufactured by CE and others, including: CE/Raymond deep bowl mills; CE shallow bowl mills; Schenck Raymond roller mills; Mill services from our regional centers of excellence. Journal rebuilds and exchanges assemblies rebuilt to original OEM specs; thorough inspection reports; standard parts in-stock for quick

Industrial Roller Mills Raymond Equipment for Sale

Industrial Roller Mills Raymond Equipment for Sale Wabash Power. 847-541-5600 Quote 0. 24/7 Emergency Service 847-541-5600. Canadian Customers.

Cryo Milling Material Milling AVEKA

Cryogenic milling, or cryo-milling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process. AVEKA ‘s cryogenic hammer mills can typically reduce the particle size from

High-efficient Raymond Mill Fote Machinery

5. Features of Ftmmachinery Raymond mill. 1. Large output and high grinding efficiency. Outputs of 8 to176 tons per shift (8 hours). The finished powder is uniform in fineness, and the passing rate is as high as 99%. 2.

Clirik.-Raymond Mill,Raymond Grinding

Raymond Roller Grinding Mill Machine Maxing Feeding Size:40 mmOuput Size:0.613-0.033 micron (40-400 mesh)Capacity:1-25 t/hD97 2021-08-17 CLIRIK YGM1850 Raymond Grinding Roller M

RAYMOND® ROLLER MILLS arvos-group pdf4pro

RAYMOND® ROLLER MILLS arvos-group. RAYMOND ROLLER MILLSWith more than 125 years of experience, Raymond is a leader in the design and manufacture of industrial milling equipment and has set the standard in size INDUSTRY STANDARD FOR OVER A CENTURYR aymond ROLLER MILLS: More than 2,000 ROLLER MILLS have

Roll Mills for PlasticRubber Industries Perry Videx

Pellet Mills (9) Pelletizer Pan (3) Raymond Roller Mills (1) Rietz Type Disintegrator Mills (6) Roll Mills 2, 3 or More Rolls (14) Cryogenic Tanks (13) Freezer (2) Miscellaneous Lined Tanks (47) Used one roller Mill manufactured by Buzuluk type MOA 2. Roller length is 1000 mm (39″) X diameter 400 mm (14″).

Used Pellet Mills For Sale Perry Videx

We offer used Pellet Mills originally manufactured by the most respected names in the industry such as CPM, Sprout and Bliss. Available for immediate delivery and competitively priced. Perry Videx: 25 Hainesport-Mt Laurel Road, Hainesport, NJ 08036, USA. +1 609 267 1600 United States United States Perry Videx Perry Videx en Español Perry Products

Used Raymond Mills Roller, Vertical, Bowl For Sale Machinery

Mill, Raymond, Imp, Model 83, 400 HP, Pre-Heater #D739613. Add to cart. Mill, Raymond, Bowl, Mdl 573, 26,000# coal/hr #C738790

Raymond Mills Raymond Roller Mill Grinding Mill AGICO

Raymond mill is also called Raymond roller mill. It is a new type of high-fineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball mill. This kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc.

Used Roller Mills Raymond, Williams, etc. For Sale Machinery

M&E buyssells Used Roller mills including Raymond models 3036, 5057, 6058, 73412 with single and double whizzer separators. Contact us today.

How to Maintain My Raymond Mill to Improve the Efficiency?

2019年9月24日This type of Raymond roller mill is commonly applicable to over 280 kinds of non-combustible and non-explosive materials with Mohs hardness of not more than 9.3 and a humidity of less than 6%, such as barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, limestone, activated clay, activated carbon and bentonite