White Cement Plant Manufacturing

White cement manufacturing process AGICO Cement Plant

The white cement manufacturing process is similar to the Portland cement

进一步探索

Difference Between Grey Cement and White CementWhite Cement Manufacture, Properties and Uses The 根据热度为您推荐•反馈

Our Operations LEHIGH WHITE CEMENT

The white line was added and inaugurated in 1969. In 1980, HeidelbergCement Group

White Cement Market IMARC Group

White cement refers to a construction material which provides excellent durability along

White Cement Manufacturing AGICO Cement Plant

In white cement plants, the main manufacturing process includes six steps: raw

White Cement Manufacturers, Companies, Suppliers

2021年6月30日Top Largest Manufacturing Companies in the White Cement Industry

White Cement Manufacturing Process AGICO White

White cement (or white Portland cement) is a kind of hydraulic cementitious material,

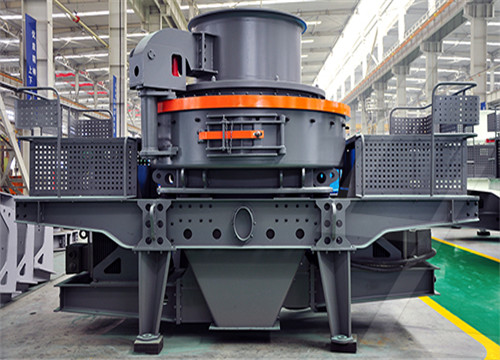

Cement Plant Cement Manufacturing Plant EPC Project

The cement manufacturing plant can be divided into five steps: Crushing

About JK Cement Vision Mission Board of Directors

JK Cement Ltd is a top putty and cement brand in India. Manufacturing the world's best

Lehigh Cement Company LLC and Lehigh White Cement

2023年1月19日This settlement is with two companies, Lehigh Cement Company LLC

Lehigh White Cement

Leading supplier and distributor of white cement in North America, operating the only two white cement manufacturing plants in the USA and the widest distribution network in the country, with 31 distribution centers. Read more. Our Operations Health and Safety Lehigh White Cement Company is committed to sustainable development; meeting

Our Operations LEHIGH WHITE CEMENT

The white line was added and inaugurated in 1969. In 1980, HeidelbergCement Group purchased the plant as part of its acquisition of the Universal-Atlas Cement Division of U.S. Steel, and merged the operation with the Lehigh White Cement Company. Grey cement plant was shut down and white cement became the core manufacturing product.

Raw Material Requirement in White Cement Production AGICO

Requirement of White Cement Raw Material. The mineral composition of white cement clinker is basically the same as that of ordinary portland cement (OPC) clinker, mainly C 3 S and C 2 S. The difference is that there is little iron phase mineral C 4 AF in white cement clinker, which is because Fe 2 O 3 has a great impact on the whiteness of cement.

About JK Cement Vision Mission Board of Directors Our Mentor

The White Cement plant was commissioned in 1984 at Gotan, Rajasthan, with an initial production capacity of 50,000 tons. JK Cement Works, Muddapur Situated near Muddapur village of Taluka- Mudhol, district Bagalkot (Karnataka, the unit has the latest state of the art technology to manufacture 3.0 Million tonnes of cement per annum.

Our Profile JK Cement

The White Cement plant uses technical expertise from F.L. SmidthCo., Denmark and state of the art technology with continuous on-line quality control. The manufacturing facility in Gotan, Rajasthan today has a

Asian Paints announces Rs 2,400-cr capex plans for two manufacturing

2022年10月20日Asian Paints on Thursday announced Rs 2,100 crore of phased investment to set up a new plant to produce vinyl acetate ethylene emulsion (VAE) and vinyl acetate monomer (VAM) in the country. The company also announced another Rs 550 crore of investment to set up a white cement plant in the UAE in partnership with two local

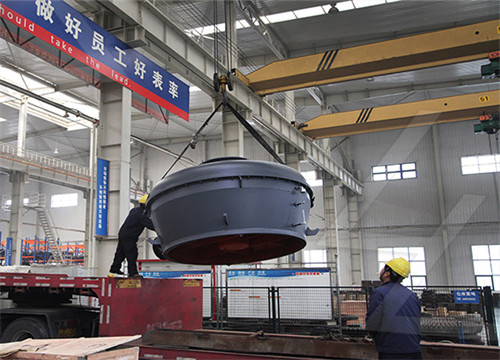

How to Start a Cement Factory AGICO Cement Plant

As a cement plant project contractor, we will directly provide clients with one-stop EPC service including engineering design and equipment supply, and help them save all the troubles on this matter. 5. Factory ConstructionEquipment Installation The cement factory is under construction.

Project Report on WHITE CEMENT Manufacturing Process

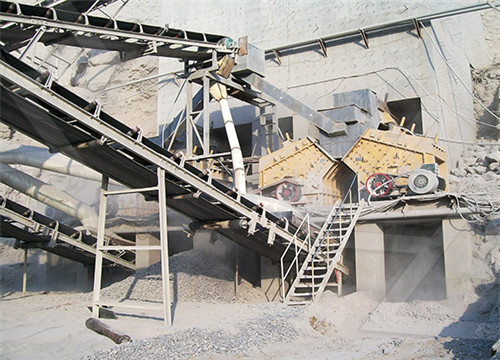

Just like general cement manufacturing plant, the white cement manufacturing process can be generally divided into six steps: Crushing: Carbonate composition mostly uses primary crushing. Since a large number of dye oxides are concentrated in the fine particles, it is best to screen the fine particles before feeding them into the cement crusher

Pallet Wrapping Machine Pallet Wrappers for Sale AGICO CEMENT

Pre-Strech Pallet Wrapper. This model stretches the film before wrapping it around the load, which can help reduce the amount of film needed and improve the efficiency of the wrapping process. Feature. Specification. Wrapping Specification. (500-1200)mm × (500-1200)mm (L×W) Max Packing Height. 2000mm/2400mm/2800mm. Packing Efficiency.

EPA Names Most Energy-Efficient Manufacturing Plants of 2022

2023年3月1日T he U.S. Environmental Protection Agency (EPA) revealed the 86 U.S. manufacturing plants to earn the agency’s ENERGY STAR certification in 2022, a designation reserved for manufacturing plants in the top 25% of energy efficiency in their sector. Together, these plants saved over 105 trillion British thermal units (Btus) of

JPSA Dry cement manufacturing equipment with

manufacturing equipment dry cement cement manufacturing precalcining furnace precalcining Prior art date 1980-07-09 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Pending Application number

Pallet Wrapping Machine For Sale Pallet Wrapper Factory Price

White Cement Manufacturing Process. Oil Well Cement Production. Masonry Cement Plant. Gypsum board production line. Slag Cement Manufacturing Process. AGICO CEMENT supplies EPC projects for both cement plant and single cement plant equipment. CONTACT INFO +86 . info@cement-plants. 19F, Suite B, Global

11.6 Portland Cement Manufacturing US EPA

White portland cement has lower iron and manganese contents than gray portland cement and is used primarily for decorative purposes. Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The six-digit Source Classification Code (SCC) for portland

136 Cement Plant Engineer Jobs and Vacancies 11 March 2023

136 Cement Plant Engineer jobs available on Indeed.

Lehigh White Cement

Leading supplier and distributor of white cement in North America, operating the only two white cement manufacturing plants in the USA and the widest distribution network in the country, with 31 distribution centers. Read more. Our Operations Health and Safety Lehigh White Cement Company is committed to sustainable development; meeting

Our Operations LEHIGH WHITE CEMENT

The white line was added and inaugurated in 1969. In 1980, HeidelbergCement Group purchased the plant as part of its acquisition of the Universal-Atlas Cement Division of U.S. Steel, and merged the operation with the Lehigh White Cement Company. Grey cement plant was shut down and white cement became the core manufacturing product.

Birla White Cement completes 25 years of operations

Birla White has one of the largest white cement plants in South East Asia, with an installed capacity of 560,000 TPA, and among the most technologically-advanced in the world. To cater to the growing market, Birla White recently commissioned a manufacturing facility for WallCare Putty at Katni, Madhya Pradesh, with a production capacity of

11.6 Portland Cement Manufacturing US EPA

White portland cement has lower iron and manganese contents than gray portland cement and is used primarily for decorative purposes. Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The six-digit Source Classification Code (SCC) for portland

Raw Material Requirement in White Cement Production AGICO

Requirement of White Cement Raw Material. The mineral composition of white cement clinker is basically the same as that of ordinary portland cement (OPC) clinker, mainly C 3 S and C 2 S. The difference is that there is little iron phase mineral C 4 AF in white cement clinker, which is because Fe 2 O 3 has a great impact on the whiteness of cement.

Our Profile JK Cement

The White Cement plant uses technical expertise from F.L. SmidthCo., Denmark and state of the art technology with continuous on-line quality control. The manufacturing facility in Gotan, Rajasthan today has a

Asian Paints announces Rs 2,400-cr capex plans for two manufacturing

2022年10月20日Asian Paints on Thursday announced Rs 2,100 crore of phased investment to set up a new plant to produce vinyl acetate ethylene emulsion (VAE) and vinyl acetate monomer (VAM) in the country. The company also announced another Rs 550 crore of investment to set up a white cement plant in the UAE in partnership with two local

Project Report on WHITE CEMENT Manufacturing Process

Just like general cement manufacturing plant, the white cement manufacturing process can be generally divided into six steps: Crushing: Carbonate composition mostly uses primary crushing. Since a large number of dye oxides are concentrated in the fine particles, it is best to screen the fine particles before feeding them into the cement crusher

Pallet Wrapping Machine Pallet Wrappers for Sale AGICO CEMENT

Pre-Strech Pallet Wrapper. This model stretches the film before wrapping it around the load, which can help reduce the amount of film needed and improve the efficiency of the wrapping process. Feature. Specification. Wrapping Specification. (500-1200)mm × (500-1200)mm (L×W) Max Packing Height. 2000mm/2400mm/2800mm. Packing Efficiency.

EPA Names Most Energy-Efficient Manufacturing Plants of 2022

2023年3月1日T he U.S. Environmental Protection Agency (EPA) revealed the 86 U.S. manufacturing plants to earn the agency’s ENERGY STAR certification in 2022, a designation reserved for manufacturing plants in the top 25% of energy efficiency in their sector. Together, these plants saved over 105 trillion British thermal units (Btus) of

Pallet Wrapping Machine For Sale Pallet Wrapper Factory Price

White Cement Manufacturing Process. Oil Well Cement Production. Masonry Cement Plant. Gypsum board production line. Slag Cement Manufacturing Process. AGICO CEMENT supplies EPC projects for both cement plant and single cement plant equipment. CONTACT INFO +86 . info@cement-plants. 19F, Suite B, Global

11.6 Portland Cement Manufacturing US EPA

1971年8月17日White portland cement has lower iron and manganese contents than gray portland cement and is used primarily for decorative purposes. Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The six-digit Source

Cement Manufacturing Process: 6 StepsTo Make Cement AGICO Cement Plant

2020年1月27日6 steps of the cement manufacturing process. When we talked about the manufacturing of cement, anyone who knows the cement manufacturing process slightly will mention “two grinding and one calcination”, they are namely: cement raw material preparation, clinker production, and cement grinding. In the real cement production line,