Secondary And Tertiary Crushing

Downstream Crushing Options for Secondary, Tertiary and

Types of Secondary CrushersTypes of Tertiary and Quaternary CrushersChoosing The Right Secondary Crusher

Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crushermay be applied as a secondary crusher. Cone Crushers Cone Crushersare compression-type crushers, which reduce material as it advances d在mclanahan上查看更多信息What is secondary crushing?查看关于此结果的此主题和其他主题

Crusher an overview ScienceDirect Topics

Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1

进一步探索

5 Types Of Stone Crushers Application and MaintenanceTypes of Crushers Mineral ProcessingMetallurgy根据热度为您推荐•反馈

Cone Crusher an overview ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and

SecondaryTertiary Crushing Circuits Mineral

2015年7月24日Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher. Within a secondary and

What is Primary, Secondary and Tertiary Crushing? Polygonmach

2022年11月5日Secondary crushing is the second stage of material processing after the first crushing. After that, the product to be crushed will pass through a second crusher or

Types of Rock Crushers Quarry Crushing Equipment

In secondary crushing, reduction ratios become an essential consideration. Knowing just how fine you need your final output to be, along with the feed requirements of your tertiary or final reduction crushing

What is Primary, Secondary and Tertiary Crushing?

2022年6月27日Secondary crushing is the second stage of material processing after the first crushing. After that, the product to be crushed will pass through a second crusher or

Crushing in Mineral Processing Eastman Rock Crusher

2020年4月20日The 20-150 mm fraction is transported to the secondary crusher on conveyor belts. The product from the secondary crusher is classified into macadam fractions such as 8-16 mm, 16-32 mm and 32

Secondary Crushing Equipment Mineral Processing

2016年2月28日The term “ secondary crushing ” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the

(PDF) COMPARISON OF SECONDARY CRUSHING OPERATIONS

2020年9月20日Likewise, 4S crushing had primary, secondary, tertiary and quaternary crushers as Jaw, Jaw, HSI and VSI (vertical shaft impactor), respectively. The 4S had an additional VSI crusher to 3S crushing.

What is Primary, Secondary and Tertiary Crushing?

2022年6月27日Secondary crushing is the second stage of material processing after the first crushing. After that, the product to be crushed will pass through a second crusher or a cone crusher, which is

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日Both are used in the secondary or tertiary crushing process but still have many differences. Roll crushers reduce material by force generated from two relatively rotating drums. First, the material enters the feed opening along with the high-speed rotating roller drums, then it got crushed by strong compressive forces in the crushing chamber

What Is Primary, Secondary, and Tertiary Crushing?

Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor crusher or even a cone crusher, which is effective at breaking down these types of material. There are also tertiary and even quaternary stages of crushing that

TECHNOLOGICAL PARAMETER ANALYSIS IN THE

2015年6月17日During 2011 to 2013 year the secondary-tertiary crushing department of the “Assarel” concentrator, the largest copper ore processing factory on the Balkans has been renovated implementing

Secondary Crushing Equipment Mineral Processing

2016年2月28日The term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the

Value-Added Solutions to Maximize Crushing Efficiency

2023年3月9日ME Elecmetal is the leader in offering wear solutions to crusher operators. We provide Crusher Wear Parts for primary, secondary and tertiary crushing applications for the mining, aggregate and

Why is a jaw crusher used to crush aluminum ore?

2023年3月7日They are versatile machines that can be used in various applications, including primary crushing, secondary crushing, and tertiary crushing. Like Comment Share. To view or add a comment,

Cone crusher Pi Kon 300 Pi Makina stationary / secondary / tertiary

Cone crushers are designed to crush hard and a corrosive brook and quarry materials such as granite, basalt, and andesite. It is used as a secondary and tertiary crusher. The maximum input size is 135-215 mm. The principle of operation of cone crushers is to crush the materials with the effect o...

Tertiary Crushers Market Share, Growth, Size, Merger, Demand,

2023年3月8日Mar 08, 2023 (The Expresswire) -- The "Tertiary Crushers Market" research report provides an in-depth analysis of the current trends, latest expansions,...

What Is The Difference Between Primary, SecondaryTertiary

2023年3月7日The primary packaging is the closest to the product and protects it, like a can for a soft drink. The secondary packaging adds an extra layer of protection and organizes the products for display, like a corrugated box or shrink wrap for a 12-pack of soda cans. Tertiary packaging is used to protect the products during storage and

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste. The primary stage was once viewed merely as a means to further reduce stone following the blast or excavation

Crushing 101 Different types of crushers for distinctive needs

2020年12月17日Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not

Food chains webs (article) Ecology Khan Academy

The level above the producers shows the primary consumers that eat the producers. Some examples are squirrels, mice, seed-eating birds, and beetles. Primary consumers are in turn eaten by secondary consumers, such as robins, centipedes, spiders, and toads. The tertiary consumers such as foxes, owls, and snakes eat secondary and primary

What Is Primary, Secondary, and Tertiary Crushing?

Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor crusher or even a cone crusher, which is effective at

(PDF) COMPARISON OF SECONDARY CRUSHING OPERATIONS

2020年9月20日Likewise, 4S crushing had primary, secondary, tertiary and quaternary crushers as Jaw, Jaw, HSI and VSI (vertical shaft impactor), respectively. The 4S had an additional VSI crusher to 3S crushing.

Blast injury Wikipedia

It is a complex clinical syndrome caused by the combination of all blast effects, i.e., primary, secondary, tertiary and quaternary blast mechanisms. Blast injuries usually manifest in a form of polytrauma, i.e. injury involving multiple organs or organ systems.

Why is a jaw crusher used to crush aluminum ore?

2023年3月7日The crushing process reduces the size of the ore particles, allowing for easier extraction of the aluminum metal. Additionally, a jaw crusher can be used to crush other types of ores, such as...

Value-Added Solutions to Maximize Crushing Efficiency

2023年3月9日ME Elecmetal is the leader in offering wear solutions to crusher operators. We provide Crusher Wear Parts for primary, secondary and tertiary crushing applications for the mining, aggregate and...

Tertiary Crushers Market Share, Growth, Size, Merger, Demand,

2023年3月8日Mar 08, 2023 (The Expresswire) -- The "Tertiary Crushers Market" research report provides an in-depth analysis of the current trends, latest expansions,...

Cone crusher Pi Kon 300 Pi Makina stationary / secondary / tertiary

Cone crushers are designed to crush hard and a corrosive brook and quarry materials such as granite, basalt, and andesite. It is used as a secondary and tertiary crusher. The maximum input size is 135-215 mm. The principle of operation of cone crushers is to crush the materials with the effect o...

Food chains webs (article) Ecology Khan

The level above the producers shows the primary consumers that eat the producers. Some examples are squirrels, mice, seed-eating birds, and beetles. Primary consumers are in turn eaten by secondary consumers,

secondary crushing MiningQuarry Plant

2013年3月12日Primary Secondary Tertiary Crushing 34 Views. The kefid is the professional mining equipments manufacturer in the world, located in China,India, along with other

What Is The Difference Between Primary, SecondaryTertiary

2023年3月7日The primary packaging is the closest to the product and protects it, like a can for a soft drink. The secondary packaging adds an extra layer of protection and organizes the products for display, like a corrugated box or shrink wrap for a 12-pack of soda cans. Tertiary packaging is used to protect the products during storage and

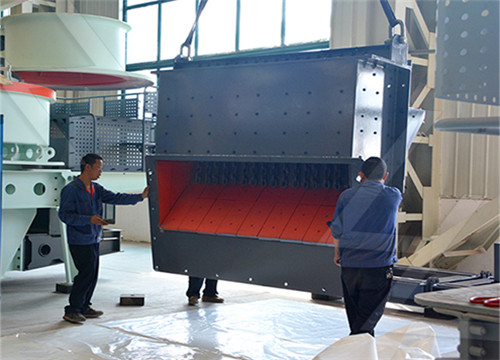

Secondary crusher, Secondary crushing and screening plant All

Applications: Secondary mediumfine crusher is widely used in mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy. Specifications impact crusher K series mobile high-capacity secondary Capacity: 45 t/h 430 t/h

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日Cone crushers are used in secondary, tertiary and quaternary stages. With proper choke-feed, cone-speed and reduction-ratio settings, cone crushers will efficiently produce material that is high quality and cubical in nature. In secondary stages, a standard-head cone is usually specified.

Secondary crusher, Secondary crushing and screening plant All

The EDGE RS1500 roll sizer has been designed for the secondary and tertiary crushing of medium-hard, sticky and soft materials such as coal, lignite, clay, limestone and other bituminous and sub-bituminous materials. Boasting Compare this product Remove from comparison tool. impact crusher WLF series .

Crushing plant Wikipedia

Raw materials are evenly and gradually conveyed into jaw stone crushing equipment for primary crushing via the hopper of vibrating feeder. The crushed stone materials are conveyed to crushing plant by belt conveyor for secondary crushing before they are sent to vibrating screen to be separated.