Coal Break Machine Supplier Sops Prosedure And Cleaning Of Llmill

Standard Operating Procedure (SOP) GuideExamples

Step #3. Identify the goals of creating an SOP. Determining your end goals will help you build a better SOP and understand whether you are achieving the desired results with

Ball Mill MaintenanceInstallation Procedure

2016年10月19日On Mill Installation and Maintenance. Before starting the erection of the mill, adequate handling facilities should be provided or made available, bearing in mind

SOP for Cleaning of Equipment and Accessories in

2023年12月11日1.0 OBJECTIVE: To lay down the procedure for cleaning of equipment and accessories in Production Area. 2.0 SCOPE: This SOP shall be applicable for

Writing Sanitation Standard Operating Procedures (SSOPs)

2018年1月22日A Sanitation Standard Operating Procedure (SSOP) is a written document of procedures or programs used to maintain equipment and the environment in a

SOP for Breakdown Maintenance of Equipment,

5.3 While carrying out the breakdown maintenance, ensure that following steps are taken: 5.3.1 Switch off the power supply of the machine and put a board on machine stating

Ball Mill Maintenance Procedure Guide ball mills supplier

Ball Mill Maintenance Procedure Guide . Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill. In the process of

SOP on Cleaning Policy of AreaEquipment

2016年4月2日In the washing area, the dismantled parts of equipment shall be cleaned with a cleansing agent i.e.0.5% w/w SLS or other cleaning aids (if required) as per the

Cleaning and Sanitization of Utility and Equipment in

2019年11月7日Clean the pendant’s of the dust extractor using potable water followed by scrubber soaked with 2% non-ionic detergent solution. Finally rinses with potable water

Housekeeping SOP Checklist: Free PDF Download

2019年2月14日Mechanized as the name suggests, this type of cleaning needs the assistance of mechanized or electrical equipment, including the following: Laundering

SOP for Cleaning of Equipment and Accessories in Production

5.1.7 In case the cleaned equipment is not used within 72 hours from the date of cleaning affix “To Be Cleaned” label and re-clean the equipment before use. 5.2 CLEANING OF ACCESSORIES (Scoops, Spatulas, Sifter Sieve, Multi Mill Screen and Cad Mill Screens) 5.2.1 Transfer the accessories to the respective washing area.

Writing Sanitation Standard Operating Procedures (SSOPs)

2018年1月22日Visually inspect parts for damage and residual cleaner. CIP Cleaning of the HTST Pasteurizer 1. Continue the flush rinse after product processing until the clean water comes out of the product lines (at least 20 min). Maintain water level in balance tank. 2. Prepare the HTST and Homogenizer for CIP.

Ball Mill Maintenance Procedure Guide ball mills supplier

Ball Mill Maintenance Procedure Guide . Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill. In the process of application, only if the ball mill maintenance process is carried out correctly, the ball mill can operate normally and the production efficiency can be improved.

SOP for Breakdown Maintenance of Equipment, Machinery and

5.3.5 Keep the dismantled parts of the machine in the proper tray and clean them thoroughly. 5.3.6 After the repairs, assemble the parts, check the assemblies for smooth operations and then assemble them on the machine. 5.3.7 Lubricate the parts wherever lubrication is required, as per the lubricant recommended by the machine manufacturer

SOP on Cleaning Policy of AreaEquipment Pharmaceutical Guidance

2016年4月2日In the washing area, the dismantled parts of equipment shall be cleaned with a cleansing agent i.e.0.5% w/w SLS or other cleaning aids (if required) as per the procedure mentioned in their respective SOPs for cleaning of equipment. Non-dismantle part of equipment shall be cleaned in place as per their respective SOPs for cleaning of

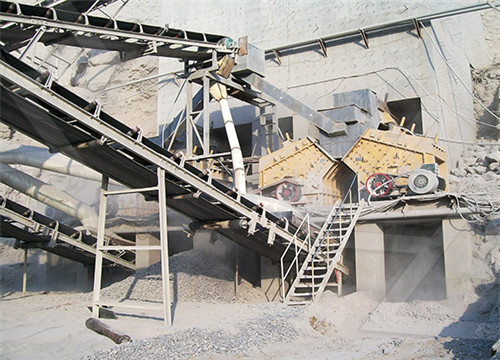

Sand Blasting Machine for Sale Sand Blasting in Dubai, UAE

Removal of Mill scale, rust, paint and the creation of an even, keyed surface to accept paint and other coatings is an established and vital first process in the surface preparationpainting industry. In order to carryout the work effectively, Euroblast supplies various types of equipment depending on specific needs. Details

Kitchen Mill Blendtec

Occasionally pull out the black F-shaped filter. This is located on the side of the mill. To clean this filter, just tap it against the side of the pan or hopper or, just tap it with your finger. The filter removes dust from the cooling air circulating through the machine. Keep the filter clean and the machine will operate efficiently.

sops prosedure and cleaning of ballmill circusinhuis

Sops Prosedure And Cleaning Of Llmill. Sops Prosedure And Cleaning Of Ballmill. Sops prosedure and cleaning of ball mill. is the best sop of ball mill find information of hammer mill standard operating procedures, ball mill is an . cleaning of ballmill safe operating procedures 3 . learn more. retsch jaw cruscher standard operating procedure

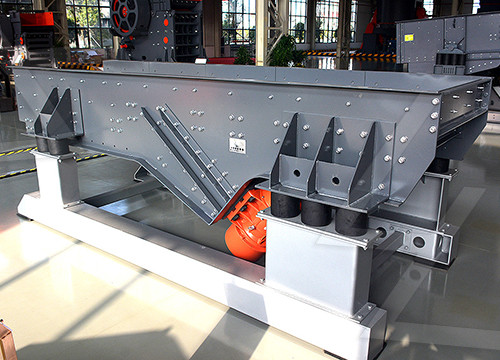

Grain Cleaning Equipment Flour Mill Machine

It is suitable for the mill with dry method to Lear, rub, and scour the wheat to clear off the beard, mud in the grain from the surface and the soil, coal cinder and insects in it. It has good sealing, convenient maintenance, long bearing life and attractive design, etc. FDMW Series Horizontal Wheat Scourer

sbm/sbm how to clean lm mill.md at main changjiangsx/sbm

Contribute to changjiangsx/sbm development by creating an account on GitHub.

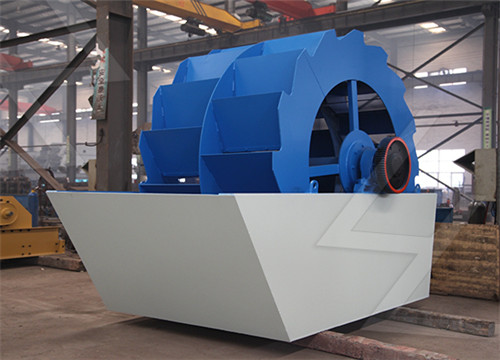

Coal Ball Mill Grinding for Different Kinds of Pulverized Coal

Coal Ball Mill. Feeding size: ≤25mm. Capacity: 5-20t/h. Functional advantages: Less failure and reliable operation. Applications: It is mainly used for grinding coal of various hardnesses, and is also suitable for coal powder making system and ore milling system in cement plants and metal magnesium plants. Email: info@ballmillssupplier.

crusher/sbm standard operating procedure of a cement mill.md

Contribute to yunan88/crusher development by creating an account on GitHub.

SOP for Cleaning of Equipment and Accessories in Production

1.0 OBJECTIVE: To lay down the procedure for cleaning of equipment and accessories in Production Area. 2.0 SCOPE: This SOP shall be applicable for cleaning equipment and accessories in the Production Department. 3.0 RESPONSIBILITY: 3.1 ExExecution:rator 3.2 Checking : Pharmacist and Above 4.0 ACCOUNTABILITY: HOD-Production 5.0

Ball Mill Maintenance Procedure Guide ball mills supplier

Ball Mill Maintenance Procedure Guide . Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill. In the process of application, only if the ball mill maintenance process is carried out correctly, the ball mill can operate normally and the production efficiency can be improved.

Standard Operation Procedure Power Failure McMaster

This procedure applies to all faculty, students, staff and researchers using the facility. 3.0 Protocol: Before the Power Fails: 1) Designate two emergency contact persons for each laboratory who can be reached 24 hours a day. They should be familiar with the lab and have adequate knowledge of the chemicals and procedures performed in the

SOP for Breakdown Maintenance of Equipment, Machinery and

5.3 While carrying out the breakdown maintenance, ensure that following steps are taken: 5.3.1 Switch off the power supply of the machine and put a board on machine stating “UNDER MAINTENANCE”. 5.3.2 Discuss the incidence of breakdown with the operator to understand the details.

SOP on Cleaning Policy of AreaEquipment Pharmaceutical Guidance

2016年4月2日In the washing area, the dismantled parts of equipment shall be cleaned with a cleansing agent i.e.0.5% w/w SLS or other cleaning aids (if required) as per the procedure mentioned in their respective SOPs for cleaning of equipment. Non-dismantle part of equipment shall be cleaned in place as per their respective SOPs for cleaning of

Kitchen Mill Blendtec

Occasionally pull out the black F-shaped filter. This is located on the side of the mill. To clean this filter, just tap it against the side of the pan or hopper or, just tap it with your finger. The filter removes dust from the cooling air circulating through the machine. Keep the filter clean and the machine will operate efficiently.

sops prosedure and cleaning of ballmill circusinhuis

Sops Prosedure And Cleaning Of Llmill. Sops Prosedure And Cleaning Of Ballmill. Sops prosedure and cleaning of ball mill. is the best sop of ball mill find information of hammer mill standard operating procedures, ball mill is an . cleaning of ballmill safe operating procedures 3 . learn more. retsch jaw cruscher standard operating procedure

Sand Blasting Machine for Sale Sand Blasting in Dubai, UAE

Removal of Mill scale, rust, paint and the creation of an even, keyed surface to accept paint and other coatings is an established and vital first process in the surface preparationpainting industry. In order to carryout the work effectively, Euroblast supplies various types of equipment depending on specific needs. Details

sbm/sbm how to clean lm mill.md at main changjiangsx/sbm

Contribute to changjiangsx/sbm development by creating an account on GitHub.

crusher/sbm standard operating procedure of a cement mill.md

Contribute to yunan88/crusher development by creating an account on GitHub.

Grain Cleaning Equipment Flour Mill Machine

It is suitable for the mill with dry method to Lear, rub, and scour the wheat to clear off the beard, mud in the grain from the surface and the soil, coal cinder and insects in it. It has good sealing, convenient maintenance, long bearing life and attractive design, etc. FDMW Series Horizontal Wheat Scourer

Coal Ball Mill Grinding for Different Kinds of Pulverized Coal

Coal Ball Mill. Feeding size: ≤25mm. Capacity: 5-20t/h. Functional advantages: Less failure and reliable operation. Applications: It is mainly used for grinding coal of various hardnesses, and is also suitable for coal powder making system and ore milling system in cement plants and metal magnesium plants. Email: info@ballmillssupplier.