Ball Mill Crusher Practical Discussion

ScienceDirect Science, health and medical journals, full text

ScienceDirect Science, health and medical journals, full text

Ball Mill Explained saVRee

根据热度为您推荐•反馈

Practical 1 : Ball Milling TF Lab 1

2013年12月23日A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The

Ball Mill Grinding Theory Crushing Motion/Action Inside

2017年4月28日Some of the conclusions drawn from this test are that: (a) The ball-mill is naturally a machine of very large capacity; (b) if it is not

Ten Ways to Improve the Grinding Efficiency of Your Ball

2019年4月22日So how to effectively improve the grinding efficiency of ball mill is an important issue for the mineral processing plants. Here are ten ways to improve the

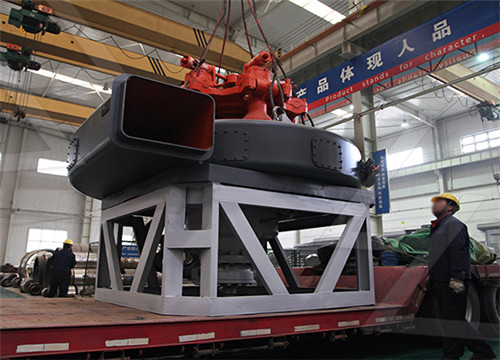

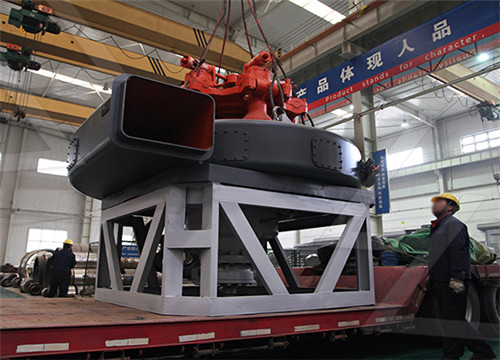

Ball Mill-Crusher

Ball mill is a principle and cylindrical revolving device, and belongs to external gear-driving ball mill. The materials are transported by feeder, and gets into mill chamber through

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

2016年5月30日A comparative study was carried out for an alloy of Al 50 (Ni 75 Mo 25) 50 processed by two different high energy ball mills. A SPEX and Simoloyer mill were used.

Ball Mills Industry Grinder for Mineral Processing JXSC

Usually, the ball filling rate is about 40%, the mill balls’ size is initially 30–80 cm diameter but gradually wore away as the ore was ground. In general, the ball mill grinder can be fed either wet or dry, the ball mill machine is

Ball Mill Working Principle And Main Parts GitHub Pages

34 行mpl ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industries.This new type

Mineral Processing Design and Operations ScienceDirect

The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for

Autogenous GrindingSemi Autogenous Grinding

2017年7月20日Autogenous grinding is favored when the ore is quite competent and a fine grind is required. Semi-autogenous grinding is applied when fine crushing could cause severe problems or when ore is

Ball Mill Grinding Theory Crushing Motion/Action

2017年4月28日Some of the conclusions drawn from this test are that: (a) The ball-mill is naturally a machine of very large capacity; (b) if it is not possible to deliver a large tonnage of original feed to the mill, a closed

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 L-capacity grinding chamber made of an abrasion-resistant elastomer, put in vibrating motion by high-tensile steel springs [28].

Ball Mill Critical SpeedWorking Principle YouTube

2015年6月20日Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM speed going from sub-critical to super-critical helps und Show more Show more...

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年5月30日A comparative study was carried out for an alloy of Al 50 (Ni 75 Mo 25) 50 processed by two different high energy ball mills. A SPEX and Simoloyer mill were used.

Ball Mill Working Animation/How does the Ball Mill

2020年4月7日Here we’ll talk about the ball mill machine working animation. By watching this video, you will know clearly how does the ball mill work. In addition, the im AboutPressCopyrightContact...

Ball Mill Eastman Rock Crusher

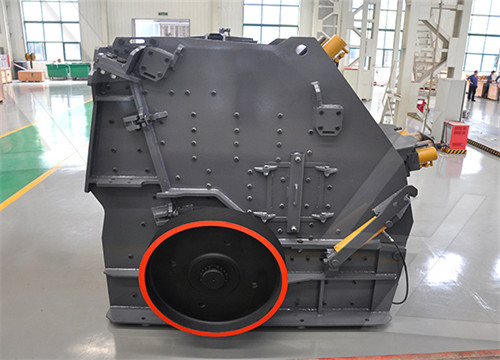

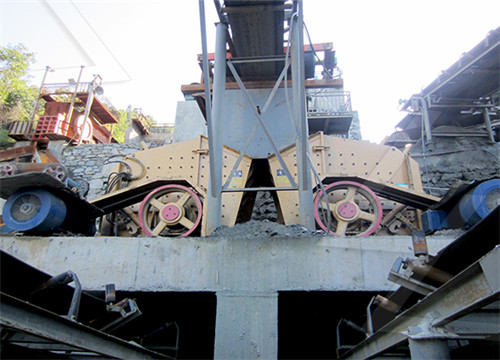

Capacity. 1-1120t/h. Output size. 10-350mm. Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit. The feed

Make a Ball Mill in 5 Minutes : 4 Steps Instructables

Step 1: What You Need You need 1. A rugged container (You can use PVC pipes or big plastic bottles) 2. An electric screwdriver (these are fairly cheap, I got mine for $10) 3. A bolt, a nut and maybe a washer. 4. Epoxy putty. 5. Steel or lead balls which in my case I substituted with screwdriver bits that I got for $3. 6.

Ball Mill Working Principle And Main Parts GitHub Pages

mpl ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industries.This new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable large-scale production.

Mini-Mill PULVERISETTE 23 / Description fritsch.de

The ultra-compact FRITSCH Mini-Mill is ideal for fine comminution of smallest quantities of medium-hard, brittle and moist samples wet, dry or cryogenic. Its special spherical grinding bowl ensures a much better performance in grinding, mixing and homogenizing compared with similar models. With a footprint of just 20 x 30 cm and a weight of

Particle size reduction, screening and size analysis Objective

pigments for inks and paints, but are quite energy inefficient. The crushing mechanism is a combination of impact with the grinding media and shearing between the media and the cylinder walls as seen in figure 1. A variation is a jar mill, in which relatively small ceramic containers holding some grinding media are rotated on a common machine

Mineral Processing Design and Operations ScienceDirect

The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for

Autogenous GrindingSemi Autogenous Grinding

2017年7月20日Crushing and grinding usually require the greatest portion of capital costs and often make up 60-70 percent of total mill operating costs as shown in Figure 1. Selection of the proper crushing and

Ball Mill Grinding Theory Crushing Motion/Action

2017年4月28日Some of the conclusions drawn from this test are that: (a) The ball-mill is naturally a machine of very large capacity; (b) if it is not possible to deliver a large tonnage of original feed to the mill, a closed

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding...

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年5月30日A comparative study was carried out for an alloy of Al 50 (Ni 75 Mo 25) 50 processed by two different high energy ball mills. A SPEX and Simoloyer mill were used.

What Are the Differences between Ball Mill and Rod

2023年2月15日1. Ball mill. a Ball mill has a wide range of applications. It can grind metal ore and non-metal ores, which is suitable for hard materials, such as quartz, gold ore, copper ore, iron ore, potash feldspar, etc. b

Ball Mill Eastman Rock Crusher

Capacity. 1-1120t/h. Output size. 10-350mm. Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit. The feed

Make a Ball Mill in 5 Minutes : 4 Steps Instructables

Step 1: What You Need You need 1. A rugged container (You can use PVC pipes or big plastic bottles) 2. An electric screwdriver (these are fairly cheap, I got mine for $10) 3. A bolt, a nut and maybe a washer. 4. Epoxy putty. 5. Steel or lead balls which in my case I substituted with screwdriver bits that I got for $3. 6.

Mini-Mill PULVERISETTE 23 / Description fritsch.de

The ultra-compact FRITSCH Mini-Mill is ideal for fine comminution of smallest quantities of medium-hard, brittle and moist samples wet, dry or cryogenic. Its special spherical grinding bowl ensures a much better

Crushers, Pulverizers, Grinders Lavallab

It is therefore extremely important to consider all individual milling parameters in order to make an informed choice: material properties, feed size and volume of the sample, grinding time and desired final particle

How to increase productivity of ball mill

2023年1月31日ball mill Use optimal grinding media: Choose the right type and size of grinding media for maximum efficiency. 1.Operate at optimal speed: The optimal speed depends on the mill diameter, the...

Cage Mill Design, Configuration, and Application

2020年2月28日Cage Mill Design, Configuration, and Application. The design of the flared-style base cage mill prevents buildup allowing the mill to processes wet, tacky, or sticky products like meat meal without clogging. Feb 28, 2020. Cage mills are a practical solution to applications that require one-step crushing to produce the final product.

Steel Balls ConsumptionBall Mill Effect JXSC Machine

The ball mill must fully consider the diameter of the ball grinding surface, the strength of the iron ore, the particle size distribution of the iron ore entering the ball mill, the compressive strength of the bearing steel balls, and the speed of the ball mill. Hammer Crusher; Double Roller Crusher; Ball Mills; Batch Small Ball Mill