Crushing And Pulverizing The Solid

Pulverizer Wikipedia

OverviewTypes of coal pulverizersBeater wheel millHammer millDemolition pulverizerSee alsoBibliography

Coal pulverizers may be classified by speed, as follows: • Low Speed• Medium Speed• High SpeedA ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in l

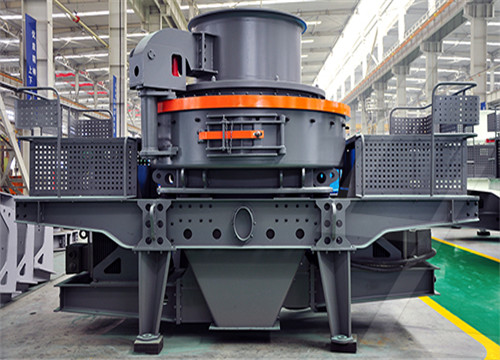

Rock Crusher MachinesPulverizers Williams Crusher

Primary, secondary, and tertiary crushers can all be used to help you find the desired size of your final product. Primary crushing starts by extracting your original material and is

进一步探索

Crushing Equipment For Sale GovPlanetSmall Jaw Crusher For Sale Low Cost Of Mini Jaw Crusher根据热度为您推荐•反馈

Pulverization 1: Definition and purpose THINKY MIXER

2019年10月31日“Pulverization” (comminution, crushing, grinding) is the process of applying an external force to a (solid) material of a certain size to destroy it and reduce it

Pulverizer Machines RuggedReliable Williams Patent

Williams roller mill pulverizers consistently deliver a uniform, fine grind for almost any application. Cylindrical rollers act as grinding elements to crush and pulverize material, creating a fine consistency. Key features of these

Crushing and pulverizing Article about Crushing and

Crushing and pulverizing The reduction of materials such as stone, coal, or slag to a suitable size for their intended uses such as road building, concrete aggregate, or

Crushers, Pulverizers, Grinders Lavallab

For over 35 years Laval Lab Inc is the one-stop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing. We serve all

Laboratory Sample Pulverizers Mineral Processing

2015年5月24日The revolving disc is attached by a ball-and-socket joint with spring tension. This enables the disc to automatically align itself with the stationary disc. The constant contact of the two discs tends to perfect the

3 Asphalt Processes to Know: Milling, Pulverizing and

Pulverizing is similar to milling, in that a huge machine drives along the roadway, ripping up existing asphalt. Unlike milling, pulverization is the first stage in reusing asphalt to re-pave the same area. Pulverization leaves

Applications of Nano Pulverization

2019年11月25日The Definition and Applications of Nano Pulverizing. “Pulverization” is another term for comminution, crushing or grinding. In other words, pulverization means

11.19.2 Crushed Stone Processing and Pulverized Mineral

Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to

Crushing and pulverizing Article about Crushing and pulverizing

Crushing and pulverizing The reduction of materials such as stone, coal, or slag to a suitable size for their intended uses such as road building, concrete aggregate, or furnace firing.

Crushers, Pulverizers, Grinders Lavallab

For over 35 years Laval Lab Inc is the one-stop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing. We serve all major

Sample Preparation Laboratory GEUS

The laboratory hosts all facilities necessary for cutting, crushing, pulverizing, powdering, sieving and for separating particular minerals from rocks and hard synthetic materials. ("Pulverisette 5" from Fritsch) performs high-speed grinding of solid or liquid samples to an average fineness of < 1 μm (depending on the material being milled

Williams CrusherPulverizer Company, Inc. > Welcome

Williams has been a leader in the crushing and pulverizing industry since 1871. With over 500 patents and trademarks to its credit, Williams Patent CrusherPulverizer Company continues to engineer new and innovative designs for crushing machines that meet the needs of clients worldwide and provide solutions for them every day.

Laboratory Sample Pulverizers Mineral Processing

2015年5月24日The ring and puck rotates inside the approximately 8” diameter cage at a speed around 400 RPM or fast enough to crush and pulverize rocks of up to ½” down to 400 mesh. SAMPLE PULVERIZER

Pulverization By Intervention Definition DEFINITIONSZE

2023年2月15日Web (n) pulverization the act of pulverizing, or reducing to dust or powder. Web Definition Of Pulverization “Pulverization” ( Comminution, Crushing, Grinding ) Is The Process Of Applying An External Force To A (Solid) Material Of

Wast Preparation, Grinding, and Sorting Zirsakht Tadbir Arian

Occasionally there may be numerous solid particles in the waste generated at the plant or a unit. In this case, it is necessary to reduce the size of these particles for easier management, and the reduction in size can be done through mechanical processes such as crushing, pulverizing, and shredding so that the remaining particles have a similar and

Tang Peidong 1 Publications 16 Citations Related Authors

Tang Peidong is an academic researcher. The author has an hindex of 1, co-authored 1 publication(s) receiving 16 citation(s).

S6 CHEMISTRY Periodic Table Quiz Quizizz

To slow down a chemical reaction you will do one of the following: answer choices Place the reactants in hot water Place the products in ice bath Place the reactants in a ice bath Keep stirring the reactants with a stirring rod Question 4 30 seconds Q. To slow down a chemical reaction you will do one of the following: answer choices

Different Ways that Adolescents Take Oxycodone Psychology

2016年3月25日Pulverizing solid capsules or tablets circulates the medication through the blood more rapidly, which creates a sudden and intense high. However, depending on the amount of the drug ingested and if the substance has time-release properties, this technique may also lead to accidental overdose. Inhalation

Pulverizer Machines RuggedReliable Williams Patent Crusher

Williams roller mill pulverizers consistently deliver a uniform, fine grind for almost any application. Cylindrical rollers act as grinding elements to crush and pulverize material, creating a fine consistency. Key features of these rugged machines include: Micrometer control of the finished product

Homogenizer for mixing and fragmenting substances

Apparatus for reducing the size of and/or for mixing solid, pasty and/or liquid material USA (en) 1974-10-08: Mill for the refining of cocoa,chocolate,paints and other similar products Crushing and pulverizing machinery. JPSA (en) 1985-06-10: Sphere machining device USA (en) 1921-05-31: Grinding-machine

What Are the Advantages of Wet Grinding vs. Dry Grinding?

Dry grinding, as in a jet mill, uses a single pass process; material enters the mill, passes through, and is expelled, reduced in size. In contrast, wet grinding uses a process of recirculation. The slurry is exposed to the grinding media over and over, for hours if necessary, until the desired particle size is achieved.

11.19.2 Crushed Stone Processing and Pulverized Mineral

Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to

Crushing and pulverizing Article about Crushing and pulverizing

Crushing and pulverizing The reduction of materials such as stone, coal, or slag to a suitable size for their intended uses such as road building, concrete aggregate, or furnace firing.

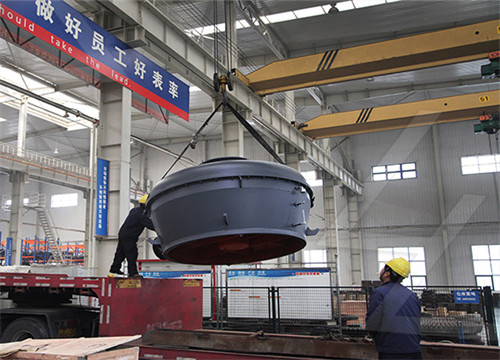

Crushing Pulverizing Grinding Wear Resistant Technologies

Crushing and pulverizing components designed to reduce the particle size of hard materials will gradually succumb to wear, requiring regular maintenance to ensure optimal performance. Yet most grinding, crushing, and pulverizing components will need replacing due to irreversible wear. The latest wear-resistant technology can significantly

Crushers, Pulverizers, Grinders Lavallab

For over 35 years Laval Lab Inc is the one-stop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing. We serve all major

Sample Preparation Laboratory GEUS

The laboratory hosts all facilities necessary for cutting, crushing, pulverizing, powdering, sieving and for separating particular minerals from rocks and hard synthetic materials. ("Pulverisette 5" from Fritsch) performs high-speed grinding of solid or liquid samples to an average fineness of < 1 μm (depending on the material being milled

Williams CrusherPulverizer Company, Inc. > Welcome

Williams has been a leader in the crushing and pulverizing industry since 1871. With over 500 patents and trademarks to its credit, Williams Patent CrusherPulverizer Company continues to engineer new and innovative designs for crushing machines that meet the needs of clients worldwide and provide solutions for them every day.

Laboratory Sample Pulverizers Mineral Processing

2015年5月24日The ring and puck rotates inside the approximately 8” diameter cage at a speed around 400 RPM or fast enough to crush and pulverize rocks of up to ½” down to 400 mesh. SAMPLE PULVERIZER

Pulverization By Intervention Definition DEFINITIONSZE

2023年2月15日Pulverization definition of pulverization by the free. Web (n) pulverization the act of pulverizing, or reducing to dust or powder. Web Definition Of Pulverization “Pulverization” ( Comminution, Crushing, Grinding ) Is The Process Of Applying An External Force To A (Solid) Material Of A Certain Size To Destroy It.

Wast Preparation, Grinding, and Sorting Zirsakht Tadbir Arian

Occasionally there may be numerous solid particles in the waste generated at the plant or a unit. In this case, it is necessary to reduce the size of these particles for easier management, and the reduction in size can be done through mechanical processes such as crushing, pulverizing, and shredding so that the remaining particles have a similar and

Tang Peidong 1 Publications 16 Citations Related Authors

Tang Peidong is an academic researcher. The author has an hindex of 1, co-authored 1 publication(s) receiving 16 citation(s).

S6 CHEMISTRY Periodic Table Quiz Quizizz

To slow down a chemical reaction you will do one of the following: answer choices Place the reactants in hot water Place the products in ice bath Place the reactants in a ice bath Keep stirring the reactants with a stirring rod Question 4 30 seconds Q. To slow down a chemical reaction you will do one of the following: answer choices

Homogenizer for mixing and fragmenting substances

Apparatus for reducing the size of and/or for mixing solid, pasty and/or liquid material USA (en) 1974-10-08: Mill for the refining of cocoa,chocolate,paints and other similar products Crushing and pulverizing machinery. JPSA (en) 1985-06-10: Sphere machining device USA (en) 1921-05-31: Grinding-machine

GBA Method and apparatus for grinding or pulverizing solid

solid materials pulverizing solid pulverizing materials Prior art date 1972-07-27 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired Application number GBA Other languages English (en)

What Are the Advantages of Wet Grinding vs. Dry Grinding?

Dry grinding, as in a jet mill, uses a single pass process; material enters the mill, passes through, and is expelled, reduced in size. In contrast, wet grinding uses a process of recirculation. The slurry is exposed to the grinding media over and over, for hours if necessary, until the desired particle size is achieved.