Ontario Iron Ore Crushing Mills

Map Ontario Mining Association

根据热度为您推荐•反馈

Northwestern Ontario iron-ore mine developer revives

2019年7月26日Ambershaw is sitting on a 335-million-ton reserve of iron ore on a 165-square-kilometre property on the west end of Bending

Mineral Processing Operating Cost Estimate of Ore

2016年9月1日The roasting cost works out at approximately $1.22 per ton of concentrate, distributed as shown in Table 99. At MacLeod Cockshutt

Stamp mill Wikipedia

OverviewDescriptionHistoryOther stamping millsSee alsoBibliographyExternal links

A stamp mill consists of a set of heavy steel (iron-shod in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down. They are lifted by cams on a horizontal rotating shaft. As the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the cam. Each one frame and stamp set is sometimes called a "battery" or, confusingly, a "stamp" and mi

The six main steps of iron ore processing Multotec

3. Feeding the crusher (Reclaim) The surge pile allows a constant supply of material to be fed into the mill, which ensures consistent results and stability in the ore recovery

Bethlehem Steel Corporation Mining Photographs

Physical Description: 19 Cubic feet. 66 boxes. Repository: Archives Center, National Museum of American History. The collection consists of approximately 28,000

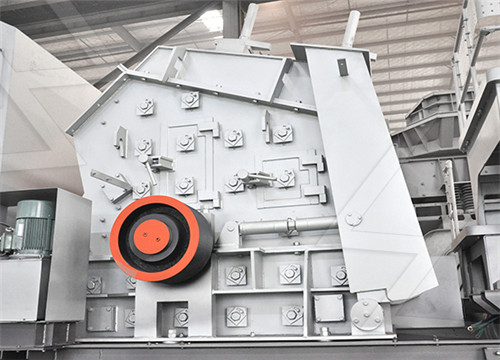

Ore, Mineral,Slag Crusher Stedman Machine Company

Mineral RocksOre Crushing Machines. Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining application. Whether you are

Edison Ore-Milling Company Wikipedia

The Edison Ore-Milling Company was a venture by Thomas Edison that began in 1881. Edison introduced some significant technological developments to the iron ore milling

Stamp mill Wikipedia

A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic ores. Breaking material down is a

Processing Citic Pacific Mining

2022年10月27日Each mill measures about 12m in diameter and has an internal volume of 1,220 cubic metres. As the AG mill turns, the ore crushes against itself and breaks apart. From the AG mills, the ore travels to the primary magnetic separators where the iron is drawn away from the waste material before it’s screened and fed into the ball mills.

The six main steps of iron ore processing Multotec

The six main steps of iron ore processing When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

Crushing in Mineral Processing

2015年12月26日Crushers for large giant process plants >2,000 to 200,000 TPD using semi-autogenous mills only require primary crushing and are selected as well as designed based on: Expected Throughput F80 Top

High pressure grinding rolls (HPGR) Metso Outotec

Robust HRC™ high pressure grinding rolls (HPGR) High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed

Report Of The Ontario Iron Ore Committee With Geology Ontario

Report Of The Ontario Iron Ore Committee With Geology Ontario

Ball Mills Industry Grinder for Mineral Processing

Ball Mills 【Capacity】 0.2-90 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max

Smelting Melting Kits Best of 2023 911Metallurgist

Smelting Furnace of Iron Ore Laboratory-scale experiments showed that pig irons and steels of acceptable grade can be made by arc-furnace methods from east Texas siliceous ores containing less than 25 percent iron.

WAY BACK WHEN IN WAYNE COUNTY: Iron ore

2011年11月13日A “paint mill” was built in Ontario, where the iron ore was ground for color and shipped around the world to be mixed with linseed oil and used as paint. The company also imported other...

China tells iron-ore traders to stop hoarding after rally

1 Iron ore erased gains on news of the measures before partially recovering. It was trading 0.6% higher at $128.35 a ton in Singapore as of 3:51 p.m. local time. It rose as much as 2.4% earlier in

STONE CRUSHERS ONTARIO Crusher Mills, Cone Crusher, Jaw

where to buy vermiculite in ontario stone crusher machine where to buy vermiculite in ontario Crushing and grinding machine supplier in all of the world: liming. ! used in stone,gold,sand,coal,iron ore,limestone,cement

ball mill for iron ore

2023年2月27日ZENITH Mineral Crusher. A ball mill is a grinding machine that is used to grind and blend materials for use in mineral processing, such as ores, pyrotechnics, ceramics, and paints. For iron ore

Cone Crusher Used in Pakistan Iron Ore Mining sbmchina

This crusher has a variety of methods, and can match with other equipment quickly. Overall, using this cone crusher for crushing iron ore has the following advantages: 1 It has good performance for crushing iron ore and other minerals which is difficult to process. 2 The finished grain type is good. And the crusher is with high crushing

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日A complete ore beneficiation plant has four stages: screening and crushing, mill grinding process, beneficiation process, and ore drying process. 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and crushing 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and

Processing Citic Pacific Mining

2022年10月27日Each mill measures about 12m in diameter and has an internal volume of 1,220 cubic metres. As the AG mill turns, the ore crushes against itself and breaks apart. From the AG mills, the ore travels to the primary magnetic separators where the iron is drawn away from the waste material before it’s screened and fed into the ball mills.

High pressure grinding rolls (HPGR) Metso Outotec

Robust HRC™ high pressure grinding rolls (HPGR) High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed

HPGR High Pressure Grinding Rolls Mineral Processing

2016年7月13日HPGRs produce a product with substantially more lines (for a given P80) than a crushing circuit. In this regard, the size distribution of an HPGR circuit is much more similar to the product of an SAG circuit than a conventional crushing circuit, reducing the amount of pow’er in the ball-mill circuit required (relative to a crushing circuit).

Report Of The Ontario Iron Ore Committee With Geology Ontario

Report Of The Ontario Iron Ore Committee With Geology Ontario

Edison Ore-Milling Company Wikipedia

Completed in 1889, the factory contained three giant electromagnets and was intended to process up to 1200 tons of iron ore every day. This mill pulverized the large chunks of ore that came directly from the mine. There was other equipment to re-refine what was left over to extract even more ore [6].

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

Ball mill, also known as ball grinding machine, is a well-known ore grinding machine, is widely used in mining, construction, aggregate application. JXSC start the ball mill business in 1985, supply globally service includes design, manufacturing, installation, and free operation training.

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation, flotation, and gravity separation, etc., iron is gradually selected from the natural iron ore.

Smelting Melting Kits Best of 2023 911Metallurgist

Smelting Furnace of Iron Ore Laboratory-scale experiments showed that pig irons and steels of acceptable grade can be made by arc-furnace methods from east Texas siliceous ores containing less than 25 percent iron. Under highly reducing conditions, 97 to 99 percent of the iron in the ore was recovered as pig iron. Small quantities of limestone,

China tells iron-ore traders to stop hoarding after rally

1 Iron ore erased gains on news of the measures before partially recovering. It was trading 0.6% higher at $128.35 a ton in Singapore as of 3:51 p.m. local time. It rose as much as 2.4% earlier in

Cone Crusher Used in Pakistan Iron Ore Mining sbmchina

This crusher has a variety of methods, and can match with other equipment quickly. Overall, using this cone crusher for crushing iron ore has the following advantages: 1 It has good performance for crushing iron ore and other minerals which is difficult to process. 2 The finished grain type is good. And the crusher is with high crushing

STONE CRUSHERS ONTARIO Crusher Mills, Cone Crusher, Jaw

where to buy vermiculite in ontario stone crusher machine where to buy vermiculite in ontario Crushing and grinding machine supplier in all of the world: liming. ! used in stone,gold,sand,coal,iron ore,limestone,cement

Ore, Mineral,Slag Crusher Stedman Machine Company

Mineral RocksOre Crushing Machines. Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining application. Whether you are processing iron ore, coal, rock, salt, chips, or clay to name a few we have your solution to size reduction. With a wide range of equipment that performs mineral and ore

ball mill for iron ore

2023年2月27日For iron ore, the grinding process is particularly important because the size and hardness of the ore can vary significantly depending on its source. The basic design of a ball mill...

Iron and Steel Industry The Canadian Encyclopedia

2006年12月14日The first ironworks in Upper Canada, the Marmora Ironworks, near Peterborough, Ontario, began production in 1822. It consisted of two charcoal-fired blast furnaces, a forge with two sets of water-powered hammers and special hearths for the production of iron bar.