Iron Ore Beneficiation Plant In Usa

Iron ore beneficiation in the USA: Past and future

2017年10月6日Download Citation On Oct 6, 2017, I Iwasaki published Iron ore beneficiation in the USA: Past and future Find, read and cite all the research you need

Energy and Environmental Profile of the U.S. Mining

4.1.2 Iron Ore Beneficiation Iron ore occurs naturally in a variety of forms, from sand-like iron fines to solid rock masses. Crude ore, or ore mined in the natural state, seldom

Iron Ore Beneficiation Primetals Technologies

Extensive knowledge of various iron ore types, combined with our holistic expertise in iron- and steelmaking, enable us to future-proof our customers’ mineral processing plants. The highest levels of automation and

10 Best Ore Beneficiation Plants for Sale (with Costs)

01 Case site 5 TPH low-grade gold ore beneficiation plant in India. 5 TPH. Raw material.

Dry beneficiation of iron ore Mineral Processing

In 2018, the Gudai-Darri (Koodaideri) iron ore project was started up with a capacity of 43 Mta, which is going into operation in the second half of 2022 with one beneficiation line

Steel News AIST

2021年12月21日12/21/2021 Metalloinvest announced last week the launch of a pilot plant at Mikhailovsky GOK intended to model iron ore beneficiation processes and

Iron Ore Beneficiation Mineral Processing

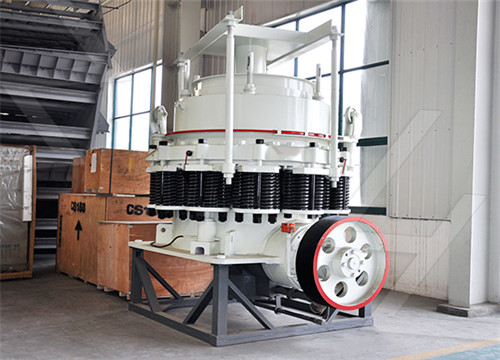

Iron Ore Processing Plant The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation,

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日Beneficiation of Iron Ore treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic type which after a

TEST WORK CONFIRMS +68% Fe HIGH GRADE IRON

beneficiation plant design needs very little change from that proposed in the 2011 Feasibility Study. Considerable costs will be saved by not repeating past design work. In

88 IRON ORE USGS

products consumed in the steel industry in the United States with an estimated value of $5.4 billion, an increase from $4.6 billion in 2018. The remaining 2% of domestic iron ore was produced for nonsteel end uses. Seven open-pit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one direct-

IRON ORE1 USGS

plants—one direct-reduced iron (DRI) plant in Louisiana and two hot-briquetted iron (HBI) plants in Indiana and Texas—operated during the year to supply steelmaking raw materials. The United States was estimated to have produced 1.5% and consumed 1.1% of the world’s iron ore output. Salient Statistics — United States: 2. 2016 2017 2018

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日Today’s pricing mechanism for iron ore has one premium for pelletization and another premium for a DR grade. The migration to DR-EAF takes place on a diverse market. Three different DR-EAF plant types can be identified: 1) The integrated DR-EAF plant using mainly a DRI burden and a minor part of internal scrap, 2)

Economic and Socio-Environmental Benefits of Dry Beneficiation

2020年10月26日The concentration plant has a processing capacity of 8 million tonnes (Mt) the application of dry processing technologies in iron ore beneficiation is a topical area of research, was US $ 10,406,000 and an annual operating cost of US $ 1,614,000 . The estimated capital cost included costs of supply, freight, tank construction, and

Steel News AIST

2021年12月21日12/21/2021 Metalloinvest announced last week the launch of a pilot plant at Mikhailovsky GOK intended to model iron ore beneficiation processes and develop new high-quality products. In a press release, the company said it developed the unique pilot plant with specialists from the TOMS Institute. “A beneficiation plant in

Technical Resource Document: Extraction and

Table 1-3. Ore Treated to Product Ratios and Material Handled to Product Ratios for U.S. Surface Iron Ore Mines, in Thousand Long Tons, 1988 .. 1-13 Table 1-4. Beneficiation Methods Commonly Associated With Iron Ores and the Percentage of Ore Treated by Each Method, 1990 .. 1-15 Table 1-5.

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日An iron ore processing plant in Indonesia, for example, conducted magnetic separation on iron ore tailings, which helped it to obtain a high-quality iron concentrate with a grade of up to 65.76%

Beneficiation of Iron Ores IspatGuru

2014年4月3日Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

Mineral beneficiation technology is the fundamental solution to the tailings problem. In view of the global tailings disasters in recent years, Noah Thompson, the chief expert of Ftmmachinery, said that "The reason is that the mineral beneficiation technology is too backward, so people cannot reasonably deal with the mine tailings. Therefore

TEST WORK CONFIRMS +68% Fe HIGH GRADE IRON ORE For

beneficiation plant design needs very little change from that proposed in the 2011 Feasibility Study. Considerable costs will be saved by not repeating past design work. In addition to the recovery test work, ore hardness, through the Crushing Work and Bond Work Indices, were measured. This shows that the CWi is about a

Iron Ore Beneficiation Primetals Technologies

IRON ORE BENEFICIATION — FROM NATURAL RESOURCES TO VALUABLE PRODUCTS Mineral processing is the cornerstone of efficient and sustainable steel production and essential to providing a high-quality

Cleveland-Cliffs' $100 million plant to use new ore technology

2019年6月7日Cleveland-Cliffs' new $100 million plant on the Iron Range will be the first in the country to use an improved technology that produces a special type of higher-quality iron-ore pellet.

Iron Ore Pelletizing Plant Iron Ore Pelletizing Pellet Plant In

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is mainly driven by the growing need for steel in end-use industries such as the automobile industry, shipbuilding industry, construction

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range

88 IRON ORE USGS

products consumed in the steel industry in the United States with an estimated value of $5.4 billion, an increase from $4.6 billion in 2018. The remaining 2% of domestic iron ore was produced for nonsteel end uses. Seven open-pit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one direct-

IRON ORE1 USGS

plants—one direct-reduced iron (DRI) plant in Louisiana and two hot-briquetted iron (HBI) plants in Indiana and Texas—operated during the year to supply steelmaking raw materials. The United States was estimated to have produced 1.5% and consumed 1.1% of the world’s iron ore output. Salient Statistics — United States: 2. 2016 2017 2018

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日Today’s pricing mechanism for iron ore has one premium for pelletization and another premium for a DR grade. The migration to DR-EAF takes place on a diverse market. Three different DR-EAF plant types can be identified: 1) The integrated DR-EAF plant using mainly a DRI burden and a minor part of internal scrap, 2)

Cleveland-Cliffs' $100 million plant to use new ore technology

2019年6月7日Cleveland-Cliffs' new $100 million plant on the Iron Range will be the first in the country to use an improved technology that produces a special type of higher-quality iron-ore pellet.

Economic and Socio-Environmental Benefits of Dry Beneficiation

2020年10月26日The concentration plant has a processing capacity of 8 million tonnes (Mt) the application of dry processing technologies in iron ore beneficiation is a topical area of research, was US $ 10,406,000 and an annual operating cost of US $ 1,614,000 . The estimated capital cost included costs of supply, freight, tank construction, and

Steel News AIST

2021年12月21日12/21/2021 Metalloinvest announced last week the launch of a pilot plant at Mikhailovsky GOK intended to model iron ore beneficiation processes and develop new high-quality products. In a press release, the company said it developed the unique pilot plant with specialists from the TOMS Institute. “A beneficiation plant in

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日An iron ore processing plant in Indonesia, for example, conducted magnetic separation on iron ore tailings, which helped it to obtain a high-quality iron concentrate with a grade of up to 65.76%

Technical Resource Document: Extraction and

Table 1-3. Ore Treated to Product Ratios and Material Handled to Product Ratios for U.S. Surface Iron Ore Mines, in Thousand Long Tons, 1988 .. 1-13 Table 1-4. Beneficiation Methods Commonly Associated With Iron Ores and the Percentage of Ore Treated by Each Method, 1990 .. 1-15 Table 1-5.

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

Mineral beneficiation technology is the fundamental solution to the tailings problem. In view of the global tailings disasters in recent years, Noah Thompson, the chief expert of Ftmmachinery, said that "The reason is that the mineral beneficiation technology is too backward, so people cannot reasonably deal with the mine tailings. Therefore

TEST WORK CONFIRMS +68% Fe HIGH GRADE IRON ORE For

beneficiation plant design needs very little change from that proposed in the 2011 Feasibility Study. Considerable costs will be saved by not repeating past design work. In addition to the recovery test work, ore hardness, through the Crushing Work and Bond Work Indices, were measured. This shows that the CWi is about a

Iron Ore Beneficiation Primetals Technologies

IRON ORE BENEFICIATION — FROM NATURAL RESOURCES TO VALUABLE PRODUCTS Mineral processing is the cornerstone of efficient and sustainable steel production and essential to providing a high-quality

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range

Iron Ore Beneficiation Process MetallurgistMineral

2017年4月27日By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being silica and moisture. The general processes to which low grade iron ores are amenable are as follows: Thermal (a) Drying; removes hydroscopic or atmospheric moisture.

Iron Ore Pelletizing Plant Iron Ore Pelletizing Pellet Plant In

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is mainly driven by the growing need for steel in end-use industries such as the automobile industry, shipbuilding industry, construction