Coal Crusher Type With Diagram Ball Mill Rotary Classifier Fitting Method

The layout of the coal mill with a rotary classifier.

The layout of the coal mill with a rotary classifier is shown in Figure 1. View in full-text Context 2 separated coal powder is conveyed into the pulverized coal pipes for burning...

Dynamic classifiers improve pulverizer performance and more

2007年7月15日A classifier separates coarse from fine coal by allowing the fine coal to pass and rejecting the coarse particles for regrinding. A dynamic classifier has an inner

sbm/sbm ball mill rotary classifier fitting method.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Pulverizer Wikipedia

OverviewTypes of coal pulverizersBeater wheel millHammer millDemolition pulverizerSee alsoBibliography

Coal pulverizers may be classified by speed, as follows: • Low Speed• Medium Speed• High SpeedA ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in l

Coal McLanahan

Employing the basic reduction principles, McLanahan crushers reduce coal at maximum volume using compression, impact, attrition and shear forces. Crushers engineered by

Ball Mill Circuit Classification System Efficiency

2018年4月22日The circulating load ratio is an excellent subject for study of classification system performance because it has long been recognized as such an important factor in

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal

Coal Mill Classifiers Air Classification

Coal Mill Classifiers Air Classification Coal Mill Classifiers Cement, lime and utilities improve kiln and combustion performance by retro-fitting static classifiers with a high

id/ball mill classifier rotary metode pas.md at main

Contribute to luoruoping/id development by creating an account on GitHub.

Rotary Crusher Diagram Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher,Ball mills,Cone crusher,Sand maker,Rotary kiln mpl Machinery provides you Stone Crusher, Jaw Crusher, Vibrating Screen,Rotary kiln, Ball mills etc.

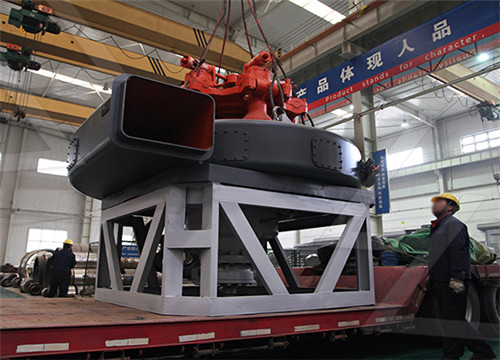

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Typical rules for primary crusher selection: Rule 1: Always use a jaw crusher if you can due to lower costs. Rule 2: For low capacity applications, use jaw crusher and hydraulic hammer for oversize. Rule 3: For high capacities, use jaw crusher with big intake openings. Rule 4: For very high capacities, use gyratory crusher. Jaw Crusher

Grinding Mill an overview ScienceDirect Topics

This type of coal mill consists of a rotating tube (diameter 2-4 m, length 3-8 m) filled with 30–60 mm cast alloy balls. The drum is filled with balls to its 20%–35% of volume. In the past, most tube-ball mills had a single inlet and outlet, but now both ends are used to feed the raw material and also to remove the powdered product.

Coal Mill Classifiers Air Classification

Ball Mills. Mill Classifiers. Roller Mill Classifiers extras. More. Coal Mill Classifiers. Cement, lime and utilities improve kiln and combustion performance by retro-fitting static classifiers with a high efficiency dynamic classifiers. 633 Raymond® Mill with MCS-250 dynamic classifier. CONTACT US. Telephone: Fax: Mailing address

Closed Circuit Grinding VS Open Circuit Grinding

2016年10月12日The usual type of two-stage circuit is shown in Fig. 26, and is one that can be employed for any degree of grinding, although a straight must be substituted for a bowl classifier in the second stage when a 48-mesh product is required.

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Oversized pulverized coal impacts with the rotating classifier and drops back onto the grinding table for further grinding. Correctly sized coal particles pass through the classifier and exit the mill through the discharge duct. Pulverized coal that has passed through the classifier is pneumatically conveyed to the furnace.

11.19.2 Crushed Stone Processing and Pulverized Mineral

crusher. Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to 1 inch), is returned to the sizing screen.

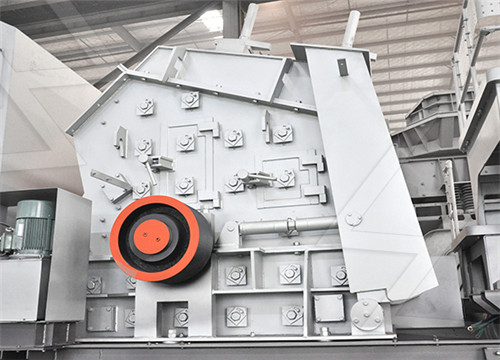

coal crusher types includes mineral sizers, Rotary Breaker, etc

Coal Crusher. Since 1990 year, ZJH mineral begin to produce and supply coal crusher for coal mining and coal power stations. Our coal crusher types includes mineral sizers, Rotary Breaker, reversible hammer mill, ring hammer crusher,double roller crusher or four roller crusher. We could produce the coal crusher according to client’s drawing

11.25 Clay Processing US EPA

to produce a uniform material. The material then is passed through a grizzly and crusher to reduce the clay pieces to less than 2.5 cm (1 in.) in size. Next, the crushed bentonite is dried in rotary or fluid bed dryers fired with natural gas, oil, or coal to reduce the moisture content to 7 to 8 percent. The

id/ball mill classifier rotary metode pas.md at main luoruoping/id

Contribute to luoruoping/id development by creating an account on GitHub.

Rotary Crusher Diagram Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher,Ball mills,Cone crusher,Sand maker,Rotary kiln mpl Machinery provides you Stone Crusher, Jaw Crusher, Vibrating Screen,Rotary kiln, Ball mills etc. If you need, please contact us, Tel: +86-371-.

Roll Crusher an overview ScienceDirect Topics

Jaw Crusher. This type of primary crusher is usually used for crushing shale to reduce it to a size suitable for handling. Roll Crusher. For a given reduction ratio, single-roll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal

rotary crushers for coal mine kooks.co.za

rotary coal crushers australia mining equipment pbcollege. Mining Products,Inc. Astec Mining Group (AMG) products have a rich history that comes from decades of a complete line of comminution and sizing equipment, as well as underground mining Rotary Coal Breakers . work in conjunction with a primary crusher.

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日Open Circuit Rod Mill followed by Closed Circuit Ball Mill. In this case the grinding circuit comprises an open circuit rod mill followed by a closed-circuit ball mill. The ball mill is most often closed over a classifier like a hydro cyclone (Fig. 3.11) or DSM style screen with a fine cut of 1–1.5 mm. The course material is returned to the

Shanghai Heavy Equipment Co., Ltd. Ball Mill, Rotary

1 set (Min. Order) 1000 tons per day Portland Cement Quick Lime Making Machine Equipment Plant/Calcined Limestone Shaft Kiln 300t/d kiln. $76,045.00 / set. 1 set (Min. Order) cement metallurgy chemical lime kiln Rotary Kiln used for the calcinations of cement clinker for hot sale. $60,000.00 $600,000.00 / set.

All Metso Corporation catalogs and technical brochures

Air Classifiers Accurate Fines Control for Engineered Sands Brochure. 8 Pages. Cyclonic Ultrafine Classifier Technical Data Sheet. 2 Pages. Metso Centrifugal Air Classifier for Fly Ash Processing. 2 Pages. Air Classifier Options Data Sheets. 2 Pages. VERTIMILL® Lime Slaker Technical Sheet and Questionnaire.

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. [1] Depending on the processes used in each instance, it is often also known as ore dressing or ore milling .

Grinding Mill an overview ScienceDirect Topics

1, Rotary classifier; 2, Oversize return; 3, Neck bearing; 4, Drive gear rim; 5, Grinding ball filling; 6, Feed spiral conveyor; 7, Classifier riser Seeking to improve the operation of tube ball mills, a new type of milling element called DOERING Cylpebs is proposed [32].

Coal Mill an overview ScienceDirect Topics

Observer-Based and Regression Model-Based Detection of Emerging Faults in Coal Mills. Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007. 5.2 Experiments with and design of the regression model-based approach. Operating data from a coal mill is used to compare the fault detection

Coal Mill Classifiers Air Classification

Ball Mills. Mill Classifiers. Roller Mill Classifiers extras. More. Coal Mill Classifiers. Cement, lime and utilities improve kiln and combustion performance by retro-fitting static classifiers with a high efficiency dynamic classifiers. 633 Raymond® Mill with MCS-250 dynamic classifier. CONTACT US. Telephone: Fax: Mailing address

Closed Circuit Grinding VS Open Circuit Grinding

2016年10月12日The usual type of two-stage circuit is shown in Fig. 26, and is one that can be employed for any degree of grinding, although a straight must be substituted for a bowl classifier in the second stage when a 48-mesh product is required.

Coal Crushers Coal PulverizersMills Williams Crusher

Through continuous innovation and dedication to quality, Williams Patent Crusher has become the industry leader in coal crushing and pulverizing equipment. We’ve maintained that commitment for over 150 years—and we strive to keep it that way. Our engineers have designed the most advanced coal pulverizing and crushing systems in the field.

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

11.25 Clay Processing US EPA

to produce a uniform material. The material then is passed through a grizzly and crusher to reduce the clay pieces to less than 2.5 cm (1 in.) in size. Next, the crushed bentonite is dried in rotary or fluid bed dryers fired with natural gas, oil, or coal to reduce the moisture content to 7 to 8 percent. The

Rotary Crusher Diagram Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher,Ball mills,Cone crusher,Sand maker,Rotary kiln mpl Machinery provides you Stone Crusher, Jaw Crusher, Vibrating Screen,Rotary kiln, Ball mills etc. If you need, please contact us, Tel: +86-371-.

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日Open Circuit Rod Mill followed by Closed Circuit Ball Mill. In this case the grinding circuit comprises an open circuit rod mill followed by a closed-circuit ball mill. The ball mill is most often closed over a classifier like a hydro cyclone (Fig. 3.11) or DSM style screen with a fine cut of 1–1.5 mm. The course material is returned to the

Impact Crusher Working Principle Mineral Processing

2015年6月23日The selection or sizing of a crusher is much helped by measuring the rock’s hardness during engineering. The various types of crushers in full scale mineral processing production include Hammermills, Impactors, Jaw Crushers, Gyratories, Single-roll crushers. Impact Crusher Buy a small impact crusher Rock Particle Breakage in

id/ball mill classifier rotary metode pas.md at main luoruoping/id

Contribute to luoruoping/id development by creating an account on GitHub.