Roller Crushing Equipment Principle

Roll Crusher an overview ScienceDirect Topics

Roll crushers apply shear or compression to the material that is going to be reduced in size. This action occurs between two hardened surfaces. The speed and diameter of the rolls, the desired capacity, and the feed and product size distribution are all critical in the proper

Roll Crushers McLanahan

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll

BTMA-What is the principle of a roller crusher? BTMA

2022年1月7日The roll crusher working principle is a physics of angular relations. When the material is too large to pass the rollers, it will not be crushed into a small particle. In

Roll crusher working principle Henan Deya Machinery Co., Ltd.

2021年8月20日The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on the core of the roll, with the tip

Types of Crushers: What You Need to Know Machinery Partner

Crushing is the process of reducing or breaking down larger-sized material into smaller-sized material. There are four basic ways to crush. The four ways of reducing material

Double Roll Crushers McLanahan

McLanahan’s mechanical tramp relief systems employ a spring-and-toggle mechanism that activates whenever an uncrushable object enters the crushing chamber. Once an excessive force is applied to the movable

The working principle and performance advantages of double

2022年9月26日The performance advantages of double roller crusher. (1) The roller crusher is small size, light weight, reasonable in model design, and can be easily

Working principle of roller crusher Advanced Machinery

Advanced Machinery Manufacture Co., Limited is a company which focus on Mining and Construction Machinery,Crusher Industrial field for 19 years until now, we are an

Roll Crusher| Double Roller Crusher |DOVE DOVE

ROLL CRUSHER OPERATING PRINCIPLE: DOVE Roll Crushers operates and perform particle crushing and size reduction, based on principal of Impact, shear and compression. The Crusher is composed of a feed

What’s a Double-Roller Crusher? Eastman Rock Crusher

2022年2月10日This series of roller crushers are mainly composed of rollers, roller support bearings, pressing and adjusting devices, and driving devices. The driving

Double Roll Crushers McLanahan

McLanahan’s mechanical tramp relief systems employ a spring-and-toggle mechanism that activates whenever an uncrushable object enters the crushing chamber. Once an excessive force is applied to the movable

Roll Crusher| Double Roller Crusher |DOVE DOVE

ROLL CRUSHER OPERATING PRINCIPLE: DOVE Roll Crushers operates and perform particle crushing and size reduction, based on principal of Impact, shear and compression. The Crusher is composed

The working principle and performance advantages of double roller crusher

2022年9月26日The performance advantages of double roller crusher. (1) The roller crusher is small size, light weight, reasonable in model design, and can be easily moved. (2) The price is relatively cheap, and it can be used to make sand and stones, which is very suitable for the sand making and stone production needs of some small stone factories.

Crushers and Their Types IspatGuru

2015年4月3日Roller crusher is a crusher that breaks material by squeezing it between two revolving metal cylinders, with axes parallel to each other and separated by a space equal to the desired maximum size

What’s a Double-Roller Crusher? Eastman Rock Crusher

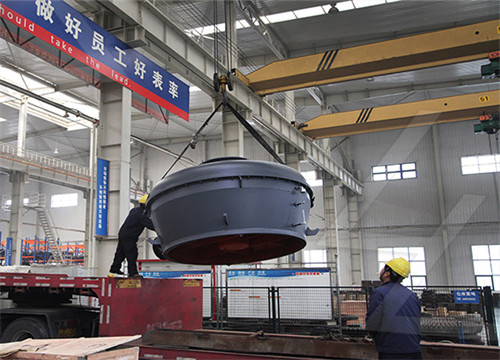

2022年2月10日This series of roller crushers are mainly composed of rollers, roller support bearings, pressing and adjusting devices, and driving devices. The driving mechanism is driven by two motors, which are driven by the V-belt to the sheave to drag the roller, and rotate according to the relative direction.

Introduction to the working principle of sizer crusher

Principle of sizers crusher The roller crusher is the common equipment of roller crushing equipment. Its driving mechanism is composed of two motors, which drive the roller wheel to the grooved wheel through the triangle belt and rotate according to the relative direction of movement.

Industrial Solutions Jaw crushers ThyssenKrupp

• Crushers can be used as stationary crushers or they can be integrated into wheel-mounted or track-mounted mobile crushing plants • Central lubrication system ensures a reliable lubricant supply From top: Single-toggle jaw crusher and double-toggle jaw crusher Over a hundred years of experience in manufacturing jaw crushers

Double Roll Crusher Henan Deya Machinery Co., Ltd.

2012年7月30日The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other. The set is determined by shims which cause the spring-loaded roll to be held back from the solidly mounted roll. Double Roller Crusher Working Principle 2 roller Material

Double Roller Crusher JXSC Machine

【 Working Principle of Double Roller Crusher 】The roller of the roller crusher is supported by the spring pressure. Under normal working conditions, the spring force is sufficient to overcome the crushing force

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

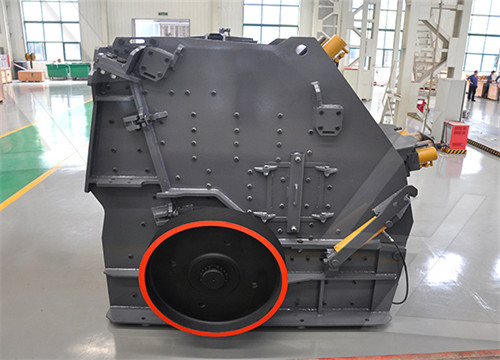

Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine, building materials and metallurgy. The grain size of the input material is large, the particle size of the output product can be controlled, and it is possible to effectively destroy

Design and experimental research on the counter roll differential

When the rotation speed of the upper fertilizer roller is 238 r/min and the rotation speed of the lower fertilizer roller is 374 r/min, the crushing rate of the fertilizer block is the highest. The fertilization device conducts verification tests on four fertilizer blocks with a moisture content of 8–40 %, and the crushing rate is more than 75 %.

The Principle And Equipment Of Crushing Process

Processing oil plant commonly used crushing equipment is tooth roller crusher. 1, Crusher by the feed device, crushing roller,roller distance adjustment device, transmission mechanism, base and other components. 2, The feeding device consists of a storage hopper, feeding roller,permanent magnet, feeding dripping plate, its role is to

High pressure grinding rolls (HPGR) Metso Outotec

High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed material to the desired smaller grain size.

Briquetting Machine Manufacturers from China ZYmining

Equipment of briquetting, crushing, mixing, conveying, cement, coal, manual machine-made. sand, and other complete plants are mainly manufactured. Luoyang Zhongyuan Mining Machine Manufacture Co., Ltd. is located in Luoxin Industrial Zone, Luoyang City, which is a millennium imperial capital and peony city, covering with 30000 ㎡.

Industrial Solutions Jaw crushers ThyssenKrupp

• Crushers can be used as stationary crushers or they can be integrated into wheel-mounted or track-mounted mobile crushing plants • Central lubrication system ensures a reliable lubricant supply From top: Single-toggle jaw crusher and double-toggle jaw crusher Over a hundred years of experience in manufacturing jaw crushers

The working principle and performance advantages of double roller crusher

2022年9月26日The performance advantages of double roller crusher. (1) The roller crusher is small size, light weight, reasonable in model design, and can be easily moved. (2) The price is relatively cheap, and it can be used to make sand and stones, which is very suitable for the sand making and stone production needs of some small stone factories.

Double Roll Crusher Henan Deya Machinery Co., Ltd.

2012年7月30日The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other. The set is determined by shims which cause the spring-loaded roll to be held back from the solidly mounted roll. Double Roller Crusher Working Principle 2 roller Material

Design and experimental research on the counter roll differential

When the rotation speed of the upper fertilizer roller is 238 r/min and the rotation speed of the lower fertilizer roller is 374 r/min, the crushing rate of the fertilizer block is the highest. The fertilization device conducts verification tests on four fertilizer blocks with a moisture content of 8–40 %, and the crushing rate is more than 75 %.

Four-roll Crusher Roll Crusher AGICO Roller Crusher Machine

Four-roll Crusher Working Principle Four-roll crusher can be divided into two crushing stages from top to bottom. When working, motors will drive the belt pulleys on both sides of the crusher to rotate the two pairs of rollers. Rollers of the same stage run in the opposite direction and mesh with each other.

AENG 252 :: Lecture 08

AENG 252 :: Lecture 09 :: SIZE REDUCTION EQUIPMENT FOR SIZE REDUCTION, CARE AND MAINTENANCE Unit operation in which the average size of solid pieces of is reduced by the application of .

Coal Crusher Types- Impact& Double Roller Crusher

The Working Principle Of Coal Crusher The crusher has two rotors that connect with each other. And when it works, the two rotors rotate at the same time under the drive of two motors. In the crushing cavity,

Briquetting Machine Manufacturers from China ZYmining

Equipment of briquetting, crushing, mixing, conveying, cement, coal, manual machine-made. sand, and other complete plants are mainly manufactured. Luoyang Zhongyuan Mining Machine Manufacture Co., Ltd. is located in Luoxin Industrial Zone, Luoyang City, which is a millennium imperial capital and peony city, covering with 30000 ㎡.

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine, building materials and metallurgy. The grain size of the input material is large, the particle size of the output product can be controlled, and it is possible to effectively destroy

The Principle And Equipment Of Crushing Process

Processing oil plant commonly used crushing equipment is tooth roller crusher. 1, Crusher by the feed device, crushing roller,roller distance adjustment device, transmission mechanism, base and other components. 2, The feeding device consists of a storage hopper, feeding roller,permanent magnet, feeding dripping plate, its role is to

Published Online August 2019 in IJEAST

The un-optimized equipment decreased megasse moisture from 96 to 89 %. Olaoye, J. O. (2011), developed a sugarcane juice extractor for small scale industries. The designed is The two-shaft used on each of the crushing rollers is carried by a shaft having a diameter of 28.8 mm and a length of 511 mm for the upper shaft and the lower shaft

Crushing Principle

2020年2月19日Crushing Principle. 1.Breaking method classification. Professional manufacturer of complete set of crushing equipment for 20years.Unique double roller crushing technology. Any need, pls feel

Cement Crusher Crusher In Cement Plant AGICO Cement

Hammer CrusherImpact Crusher. These two crushers are based on the impact principle of material crushing, with coarse crushing, medium crushing and fine crushing three types. Their main difference mainly lies in the broken part. The former uses the hammerhead hinged on the rotor, while the latter uses the blow bar embedded on the rotor.

TPGS-Y Hydraulic Multi-Roller Crusher wriku

It has been successfully applied in various metal and non-metal crushing industries such as construction waste treatment, iron ore, copper ore, tin, tungsten and chromium ore crushing, steel slag crushing, stone making, sand making, glass crushing and ceramic raw material crushing.