Hammer Crusher Construction Material Crushers

Hammer Crushers MEKA CrushingScreening

根据热度为您推荐•反馈

Reversible Hammer Crusher Elecon

Secondary crushing by impact action. Features. Bi direction Construction. Fine Crushing. Open bottom discharge can. Handle. Material with high moisture. Max. life of crusher internal parts. Hammer and grinding path

Types of Crushers: What You Need to Know Machinery Partner

One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer

Crusher, Crushing plant All industrial manufacturers

Crusher Crushers Do you need help making a decision? Take a look at our buying guide 137 companies 871 products What’s new? Manufacturers A Abionik (1) Aceretech (21)

Hammer Crusher Working Principle AGICO Cement Plant

The hammer crusher is a type of ore crushing equipment. It can be used to crush medium-hard brittle materials with low water content, such as limestone, gypsum, slag, coke, coal, etc. It is widely used in cement

Hammer Crusher Hammer Mill Crushers for Sale JXSC

Hammer stone crusher is a kind of equipment that crushes materials in the form of impact. Crushing the size of 600-1800 mm material to 25m or less. Hammermill machine can not only be used in stone crusher plant, sand

Single Stage Hammer Crusher for Processing Building Materials

2017年2月16日Single-stage hammer crusher is especially suitable for brittle materials such as building concrete, limestone, muddy siltstone, shale, gypsum and coal.

Crusher Hammers Material Of Construction

Hammer Crusher-An Excellent Helper in Construction This series of crusher are widely used in metallurgy, mining, chemical, cement, coal gangue, construction, sand,

Material Of Hammer Crusher Crusher Mills, Cone Crusher, Jaw

Hammer crusher is used for crushing raw materials that have compressive strength less than 150MPa such as limestone, marl, sandstone, gypsum, coal, etc Material Of

Hammer Crushers

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material. When you need an Industrial Solution...

Hammermill Crushers McLanahan

Hammermill Crushers commonly process limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke and coal. In what industries would you find Hammermill Crushers at work? Hammermills are common in the following applications: Energy plants conditioning the lime and coal for fuel

Hammer Mills for Material Reduction Williams

Williams Patent Crusher is a leading hammer mill manufacturer. Our industrial size reduction machines can handle any material size reduction job. Choose Williams machinery for efficient pulverizing and long-term

Industral Crushing Hammer Mill

2016年2月24日Key Features. • Designed with the heaviest, most wear-resistant components of any equipment of its kind, the RC Series industrial hammer mill provides by far the most economical crushing available. •

Hammer Mill Crushers Industrial Hammer Mill Crusher

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials. Hammer mills produce a finished product size that is dependent upon the following criteria: Openings in perforated screens or grate bars Number, size, and type of hammers Grinding plate setting Rotor speed Ask a Question

Crusher, Crushing plant All industrial manufacturers

Crusher Crushers Do you need help making a decision? Take a look at our buying guide 137 companies 871 products What’s new? Manufacturers A Abionik (1) Aceretech (21) Alfa Laval (1) ATM Recyclingsystems GmbH (3) B BHS-Sonthofen : Building Materials Machinery / Rec (2) Binder+Co AG (9) BOHEMIA MACHINE (2)

Hammer Crusher DBM Crushers, Grinding Mill,

Hammer crusher is a kind of equipment for crushing materials in the form of impact. Hammer crusher is suitable for crushing medium hardness materials, such as limestone, slag, coke, coal, salt, chalk, gypsum,

Single Stage Hammer Crusher for Processing Building Materials

2017年2月16日Single-stage hammer crusher is especially suitable for brittle materials such as building concrete, limestone, muddy siltstone, shale, gypsum and coal. Composed of heavy hammers, adjustable crushing plate, directed grate and safety door, the single-stage hammer crusher is mainly featured by large feed size and reduction ratio.

Hammer Crusher For Sale Large Crushing Ratio, Good Crushing

Heavy hammer crusher for sale is a stone crushing production equipment developed by Zhengzhou AIMIX Company for small and medium-sized investors with features of low investment and quick results. It combines the features of a traditional single-section hammer crusher and impact crusher, especially suitable for crushing medium hardness

Hammer Crusher Hammer Mill Crushers for Sale

Hammer stone crusher is a kind of equipment that crushes materials in the form of impact. Crushing the size of 600-1800 mm material to 25m or less. Hammermill machine can not only be used in stone crusher plant, sand

Double shaft hammer crusher for brick material crushing #brick

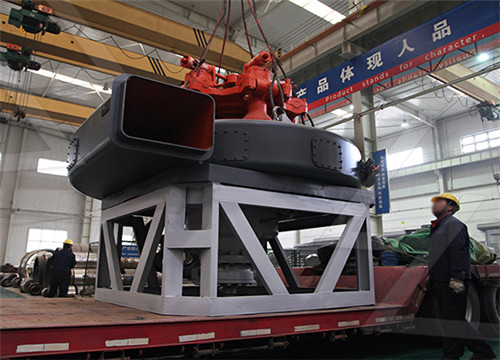

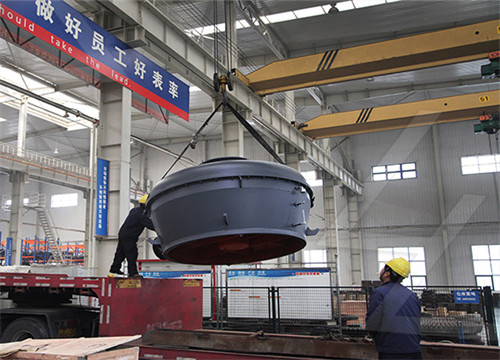

Jingying Machinery is the factory with over 30 years experience for the stone crusher line (stationary crushing line or mobile crushig line). Give me more de...

Hammer Mill CrusherGrinder Mineral ProcessingMetallurgy

2016年2月25日Capacity of Hammer Mill Crushers The capacity of any given size and type of hammermill depends upon several factors. The character of the material influences the performance of this machine to a greater degree than it does that of any of the crushers previously discussed.

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

Buyer's Guide: Crushers EquipmentContracting

Impact Crushers. An impact crusher (also called a hammer crusher) is quite versatile. It can be used as a primary, secondary, or tertiary crusher. Impact plates and beaters or hammers are used to break down the material. The material is fed through the upper part of the crusher then hit by hammers.

Hammer Crushers

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material. When you need an Industrial Solution...

HAMMER CRUSHER HDS

FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

Hammermill Crushers McLanahan

Hammermill Crushers commonly process limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke and coal. In what industries would you find Hammermill Crushers at work? Hammermills are common in the following applications: Energy plants conditioning the lime and coal for fuel

Industral Crushing Hammer Mill

2016年2月24日Key Features. • Designed with the heaviest, most wear-resistant components of any equipment of its kind, the RC Series industrial hammer mill provides by far the most economical crushing available. •

Hammer Mill Crushers Industrial Hammer Mill Crusher

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials. Hammer mills produce a finished product size that is dependent upon the following criteria: Openings in perforated screens or grate bars Number, size, and type of hammers Grinding plate setting Rotor speed Ask a Question

Hammer Crusher DBM Crushers, Grinding Mill,

Hammer crusher is a kind of equipment for crushing materials in the form of impact. Hammer crusher is suitable for crushing medium hardness materials, such as limestone, slag, coke, coal, salt, chalk, gypsum,

Hammer Mill CrusherGrinder Mineral Processing

2016年2月25日Capacity of Hammer Mill Crushers The capacity of any given size and type of hammermill depends upon several factors. The character of the material influences the performance of this machine to a

Single Stage Hammer Crusher for Processing Building Materials

2017年2月16日Single-stage hammer crusher is especially suitable for brittle materials such as building concrete, limestone, muddy siltstone, shale, gypsum and coal. Composed of heavy hammers, adjustable crushing plate, directed grate and safety door, the single-stage hammer crusher is mainly featured by large feed size and reduction ratio.

Hammer Crusher For Sale Large Crushing Ratio, Good Crushing

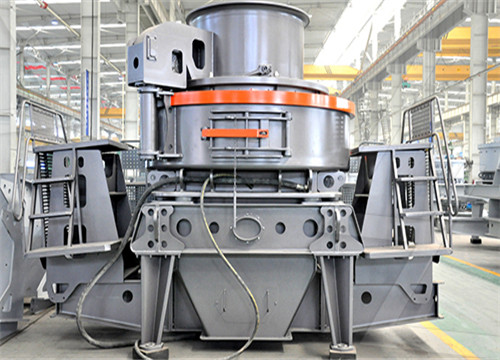

The Hammer crusher consists of housing, rotor, strike plate, hammerhead, support, liner plate, and so on. Working principle of large hammer mill crusher 1. The material to be crushed is fed into the crushing cavity by the feeding equipment through the feeding port, and the rotor drives the hammerhead to strike the material at high speed; 2.

Hammer Crusher Hammer Mill Crushers for Sale

Hammer stone crusher is a kind of equipment that crushes materials in the form of impact. Crushing the size of 600-1800 mm material to 25m or less. Hammermill machine can not only be used in stone crusher plant, sand

Hammer Mills for Material Reduction Williams

Ring Hammer Crushers Williams Ring Crushers are also known as turnings crushers. They reduce the size of metal turnings, “bullshellings,” or clips through impact crushing. Ring crushers produce their rated

Double shaft hammer crusher for brick material crushing #brick

Jingying Machinery is the factory with over 30 years experience for the stone crusher line (stationary crushing line or mobile crushig line). Give me more de...

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

Hammer crusher Titan Machinery LP stationary

Classification of Crushers by Their Construction According to their construction, crushers can be divided into the following groups: Jaw crusher Cone crusher Hammer crusher Roll crusher Disk (knife) crusher Mills can be marked out separately. The most popular types of mills are: Ball mill Vibratory mill Catalogs