Polycrystalline Silicon Carbide Crusher

Molecular dynamics study on grinding mechanism of

2022年12月1日In this simulation, three groups of silicon carbide models are established under grinding speeds of 50 m/s, 100 m/s and 200 m/s with grinding depth of 2.3 nm.

Polycrystalline silicon carbide film deposition using

2007年9月25日A polycrystalline silicon carbide film is formed on a silicon surface by atmospheric pressure chemical vapor deposition using a gas mixture of

5 Materials and Microstructures The National Academies Press

POLYCRYSTALLINE SILICON CARBIDE. The creep mechanisms in fine-grained polycrystalline SiC should be the same as the mechanisms that operate in fine-grained

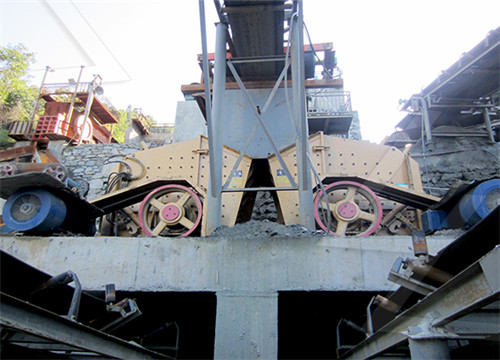

Roll crusher to produce high purity polycrystalline silicon

The polycrystalline silicon prepared by the CVD process can be comminuted into suitably sized pieces such as rods, chunks, chips, and combinations thereof, before loading into

Roll crusher to produce high purity polycrystalline silicon

The polycrystalline silicon prepared by the CVD process can be comminuted into suitably sized pieces such as rods, chunks, chips, and combinations thereof, before loading into

Polycrystalline silicon Wikipedia

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar photovoltaic and electronics industry..

Polycrystalline silicon crusher series handbreaking hammer

Polycrystalline silicon crusher series, hammer, handbreaking, artificial broken Feature: high pure Polycrystalline silicon jaw raw material, high strength, high hardness, no any

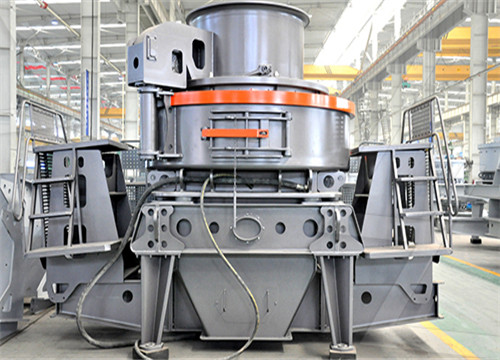

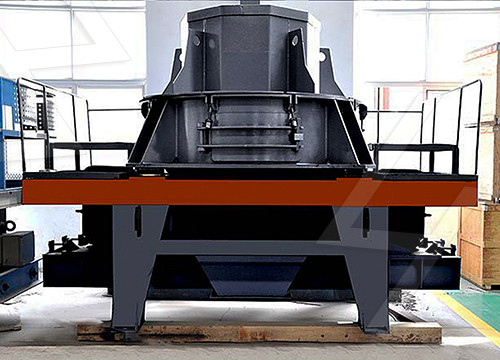

The development of silicon carbide crusher posuiman

2016年2月26日Along with the progress of The Times, the development of science and technology, the progress of technology, more and more kinds of Polycrystalline Silicon

Polycrystalline silicon jaw crusher_Zhuzhou Jinxin Cemented

Polycrystalline silicon jaw crusher-Zhuzhou Jinxin Cemented Carbide Co., Ltd_tungsten carbide-Polycrystalline silicon jaw crusher

Polycrystalline silicon crusher series handbreaking hammer

Polycrystalline silicon crusher series, handbreaking, artificial broken Feature: high pure Polycrystalline silicon jaw raw material, high strength, high hardness, no any metal in

The Cubic — To — Hexagonal Transformation to

Silicon carbide is a desirable high temperature structural material, however, its poor fracture toughness at room temperature has limited its practical application. Recent processing developments have toughened

Molecular dynamics study on grinding mechanism of polycrystalline

2022年12月1日Polycrystalline silicon carbide with grain numbers of 10, 20, 30 and 40 is randomly established by Voronoi method in a box of 8.7 nm. In this method, the spatial region is divided into a specified number of polygonal bodies according to the number of input grains. Grain seeds and crystal directions are randomly generated.

Molecular Dynamics Simulation of Nanomachining Mechanism

2021年7月3日As an advanced ceramics material, silicon carbide (SiC) is extensively applied in numerous industries. In this study, molecular dynamics method is used to comparatively investigate the nanomachining mechanism between monocrystalline SiC (mono-SiC) and polycrystalline SiC (poly-SiC) ceramics.

Design of a Silicon Carbide Chemical Vapor Deposition Reactor

2020年10月29日The 3 C polycrystalline silicon carbide plate was placed on the PPyC-coated plate. The initial sample temperature was changed between 500 °C and 600 °C. The chlorine trifluoride gas consumption by the PPyC-coated surface was assumed to be negligible. The obtained etching rate is shown in Fig. 4. At the chlorine trifluoride gas

Polycrystalline silicon carbide for surface micromachining

1996年2月15日Polycrystalline silicon carbide (poly-SiC) films have been deposited on polysilicon-coated, 4-inch silicon wafers in an atmospheric pressure chemical vapor deposition (APCVD) reactor using parameters similar to those developed by our group for single crystal SiC growth. With highly-oriented (110) polysilicon films as substrates, poly

Journal of MATERIALS RESEARCH Welcome Comments Help

C.A. Zorman et al.: Characterization of polycrystalline silicon carbide films grown by APCVD SiC films are grown in a cold-wall, rf-induction-heated, vertical APCVD reactor using the three-step growth procedure reported by us to grow 3C-SiC films on 4-inch (100) silicon wafers.20 The three-step dep-

Electropolishing of n-type 3C-polycrystalline silicon carbide

2014年3月1日The substrates used in this investigation are 4″ polycrystalline n-type 3C-SiC on Si (111); SiC layer is about 2.5 μm thick with average grain size of about 90 nm. The 3C-SiC films were deposited in a low-pressure chemical vapor deposition reactor, using methylsilane and dichlorosilane as the precursor gases and in-situ doped using ammonia

Polycrystalline silicon Wikipedia

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar photovoltaic and electronics industry .

The development of silicon carbide crusher posuiman

2016年2月26日Along with the progress of The Times, the development of science and technology, the progress of technology, more and more kinds of Polycrystalline Silicon Carbide Crusher, the crushing equipment broken in different ways, such as granularity, become the most concerned with customer, our factory according to your requirements

Polycrystalline Silicon Material Patent Application Number:

Polycrystalline Silicon Material is an invention by Takuya Asano, Yamaguchi JAPAN. This patent application was filed with the USPTO on Thursday, April 2, 2020 1-833-TMELITE

(PDF) Thermal Characterization of Polycrystalline SiC

2014年1月31日Here, LDMOS-transistors are processed and characterized on 150 mm silicon-on-polycrystalline-silicon carbide (Si-on-poly-SiC) substrates as well as on high power and RF optimized SOI reference

Polycrystalline silicon carbide as a substrate material for

2006年4月25日The in-use adhesion characteristics of polycrystalline cubic silicon carbide (poly-SiC) films when used as a substrate material in MEMS applications are investigated using micromachined polycrystalline Si (poly-Si) cantilever beam arrays. The detachment lengths greater than 1500 μm are obtained, corresponding to an apparent

Roll crusher to produce high purity polycrystalline silicon chips

2020年11月8日The roll, teeth, and at least the inside surfaces of the top, sides, and bottom are fabricated from a material of construction that minimizes contamination of silicon. The material of construction may be tungsten carbide with a cobalt binder. The single roll crusher is used for processing polycrystalline silicon.

China Customized polycrystalline-silicon-jaw-crusher Exporters

Zhuzhou Jinxin Cemented Carbide Group Co.,Ltd is a polycrystalline-silicon-jaw-crusher wholesale exporters supplier in China. our company polycrystalline-silicon-jaw-crusher are high quality, we have own factory, you can completely trust on! We are always glad to offer attractive discount and promotions if you are gonna to purchase polycrystalline

The Cubic — To — Hexagonal Transformation to

Silicon carbide is a desirable high temperature structural material, however, its poor fracture toughness at room temperature has limited its practical application. Recent processing developments have toughened

Molecular dynamics study on grinding mechanism of polycrystalline

2022年12月1日Polycrystalline silicon carbide with grain numbers of 10, 20, 30 and 40 is randomly established by Voronoi method in a box of 8.7 nm. In this method, the spatial region is divided into a specified number of polygonal bodies according to the number of input grains. Grain seeds and crystal directions are randomly generated.

Polycrystalline silicon carbide for surface micromachining

1996年2月15日Abstract: Polycrystalline silicon carbide (poly-SiC) films have been deposited on polysilicon-coated, 4-inch silicon wafers in an atmospheric pressure chemical vapor deposition (APCVD) reactor using parameters similar to those developed by our group for single crystal SiC growth.

Design of a Silicon Carbide Chemical Vapor Deposition Reactor

2020年10月29日The 3 C polycrystalline silicon carbide plate was placed on the PPyC-coated plate. The initial sample temperature was changed between 500 °C and 600 °C. The chlorine trifluoride gas consumption by the PPyC-coated surface was assumed to be negligible. The obtained etching rate is shown in Fig. 4. At the chlorine trifluoride gas

Journal of MATERIALS RESEARCH Welcome Comments Help

C.A. Zorman et al.: Characterization of polycrystalline silicon carbide films grown by APCVD SiC films are grown in a cold-wall, rf-induction-heated, vertical APCVD reactor using the three-step growth procedure reported by us to grow 3C-SiC films on 4-inch (100) silicon wafers.20 The three-step dep-

Electropolishing of n-type 3C-polycrystalline silicon carbide

2014年3月1日The substrates used in this investigation are 4″ polycrystalline n-type 3C-SiC on Si (111); SiC layer is about 2.5 μm thick with average grain size of about 90 nm. The 3C-SiC films were deposited in a low-pressure chemical vapor deposition reactor, using methylsilane and dichlorosilane as the precursor gases and in-situ doped using ammonia

Roll crusher to produce high purity polycrystalline silicon chips

The roll, teeth, and at least the inside surfaces of the top, sides, and bottom are fabricated from a material of construction that minimizes contamination of silicon. The material of construction may be tungsten carbide with a cobalt binder. The single roll crusher is used for processing polycrystalline silicon.

(PDF) Thermal Characterization of Polycrystalline SiC

2014年1月31日Here, LDMOS-transistors are processed and characterized on 150 mm silicon-on-polycrystalline-silicon carbide (Si-on-poly-SiC) substrates as well as on high power and RF optimized SOI reference

USA Precipitating highly pure compact silicon carbide

USA US842495A USA USA US A US A US A US 842495 A US842495 A US 842495A US A US A US A US A US A US A Authority US United States Prior art keywords silicon carbide silicon carrier highly pure doped Prior art date 1958-10-23

Polycrystalline Silicon Material Patent Application Number:

Polycrystalline Silicon Material is an invention by Takuya Asano, Yamaguchi JAPAN. This patent application was filed with the USPTO on Thursday, April 2, 2020 1-833-TMELITE

[PDF] Fabrication and characterization of polycrystalline SiC

2002年12月1日This stone presents the development of polycrystalline 3C silicon carbide (polySiC) lateral resonant devices, which are fabricated by a three-mask surface micromachining process using silicon dioxide (SiO/sub 2/), polysilicon, and nickel (Ni) as the isolation, sacrificial, and contact metallization layers, respectively. The polySiC

Polycrystalline Silicon Carbide Tystar

Polycrystalline Silicon Carbide. Silicon carbide's strength, thermal conductivity, and stability in extreme environments make it a useful material for electronics and MEMS. Deposition Gases: Methylsilane, Dichlorosilane, Hydrogen, Acetylene, Ammonia. NH 3 is commonly used for n-type doping while (CH 3) 3 Al is used for p-type.

Polycrystalline silicon crusher series handbreaking hammer

Polycrystalline silicon crusher series, hammer, handbreaking, artificial broken Feature: high pure Polycrystalline silicon jaw raw material, high strength, high hardness, no any metal in the surface, except tungsten carbide, stable design.