Grinding Of Raw Bauxite

Physical Bauxite Processing: Crushing and Grinding of

2022年1月23日The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly

进一步探索

Bauxite mining's unhealthy effects on people, environment Extraction Process of Aluminium from Bauxite OreThe Process of Mining Bauxite DajcorBauxite Mining's Negative Effects on Human and EnvironThe Transformation of Bauxite to Aluminum (and the Pro根据热度为您推荐•反馈

Physical Bauxite Processing: Crushing and Grinding of

2022年1月23日Download Citation Physical Bauxite Processing: Crushing and Grinding of Bauxite The most common process step to feed an alumina refinery with bauxite is

Grinding and Abrasive Machining of Composite Materials

2021年6月22日The grinding or abrasive machining of composite materials is a complex system that relies on the use of hard materials such as alumina and diamond to achieve

11.31 Abrasives Manufacturing US EPA

manufacturing is very diversified and includes the production of grinding stones and wheels, cutoff saws for masonry and metals, and other products. Before processing, bauxite,

Bauxite an overview ScienceDirect Topics

The principal uses of bauxite are multipurpose covering metallurgy, chemical industries, as raw material in building and road aggregates. Bauxite is the best and only material for

CNA Low-quality raw bauxite ore open

2013年10月19日1. a low-grade bauxite raw ore open-circuit grinding ore-dressing technique, is characterized in that it includes raw ore open-circuit grinding cyclone

Bauxite mining in the United States Wikipedia

Bauxite forms by the weathering of aluminum-rich and silica-poor rocks in hot, humid, climates, at places with good drainage. Under the proper conditions, weathering

Industrial Raw Materials Charah® Solutions

APPLICATIONS: Abrasives are used in many industries, from metal work to cleaning to -working. Common uses for abrasives include grinding, grinding down freshly cut

Extraction Process of Aluminium from Bauxite Ore

2016年4月11日grinding and digestion of bauxite in the sodium aluminate liquor, separation and washing of the coarse red mud residue from the sodium aluminate liquor.

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日Download Citation Physical Bauxite Processing: Crushing and Grinding of Bauxite The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that

Grinding Behavior and Potential Beneficiation

2020年3月31日This laboratory study investigates selective grinding and beneficiation options for a Greek bauxite ore. First, a series of batch grinding tests were carried out in order to investigate the grinding

CNA Low-quality raw bauxite ore open-grinding

2013年10月19日1. a low-grade bauxite raw ore open-circuit grinding ore-dressing technique, is characterized in that it includes raw ore open-circuit grinding cyclone classification machine technique...

Bauxite raw material processing complex (2019) Loginova Irina

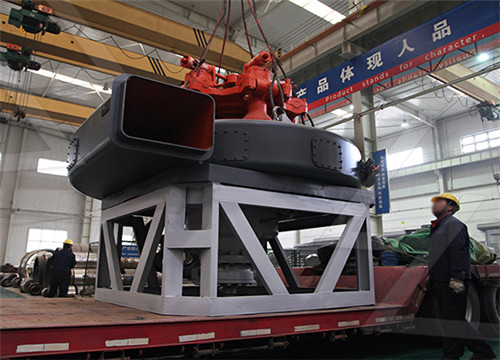

FIELD: metallurgy.SUBSTANCE: technical solution relates to non-ferrous metallurgy, particularly, to production of alumina from bauxites. Complex for bauxite raw material processing comprises two lines, in the first of which there is a crusher for crushing high-quality bauxite, mill for bauxite grinding in recycled solution, autoclave for high

Metals Free Full-Text Effective Extraction of Vanadium from Bauxite

A new bauxite-type vanadium ore with a grade of 0.96% V2O5 was found in Hanzhong, China, having quartz, illite, and calcite as the main mineral constituents and vanadium that mainly occurs in the aluminosilicate lattice of illite by replacing Al3+ with V3+ in isomorphism form. In this study, a novel process of low-temperature sulfating roasting–water leaching

Bauxite Calcination Plant by Rotary Kiln with Fine Grinding

Compared to an alumina content of about 57 % to 58 % in raw Bauxite, Calcined Bauxite has an alumina content of 82 % to 86 %. The heating is carried out in rotary kilns. Calcination is done at different temperatures ranging from 850 oC to 1600 oC depending upon the customer’s application. Calcined bauxite is used in a number of applications:

Raw material grinding plants Manfredini and Schianchi

ManfrediniSchianchi, a leading company in the treatment of raw materials, has been proposing targeted and flexible solutions for the grinding of countless types of materials. In ManfrediniSchianchi every problem of Grinding proposed to us by our customers is always previously analyzed by our technical team and by ours research laboratory

SEM photos of reduction-grinding products obtained at different

Download scientific diagram SEM photos of reduction-grinding products obtained at different reduction temperature. from publication: Study on Metallized Reduction and Magnetic Separation of Iron

Grinding Of Raw Bauxite

The grinding behavior of the bauxite ore was evaluated by identifying the relationship between the remaining mass (%) fraction of each particle size vs. grinding time. Figure 5a shows, as an example, the experimental data obtained for four selected sizes, namely 0.600, 0.300, 0.150 and 0.075 mm when the material filling volume (f c) was 5%.

1250 mesh bauxite grinding mill Popular 1250 mesh bauxite grinding

Vertical Bauxite Grinding Mill Raw Mill Cement Plant 325 1250 Mesh...1250 Mesh High Efficiency Vertical Bauxite Grinding Mill Machine Description The vertical grinding mill is widely used in such small and medium industries as mining, chemicals, building materials, metallurgy, refractories, pharmaceuticals, cement, etc.

Manufacturers of wet grinding mills for bauxite

2022年12月8日Bauxite ore grinding is the important beneficiation operations at bauxite mines used for particle size reduction for separation of mineral and waste.At the bauxite beneficiation plant, the raw bauxite ore will be fed into primary crusher for primary crushing. After the crushing process, the bauxite is screened and washed to...

Desulfurization by Adding Sodium Nitrate in the Production of

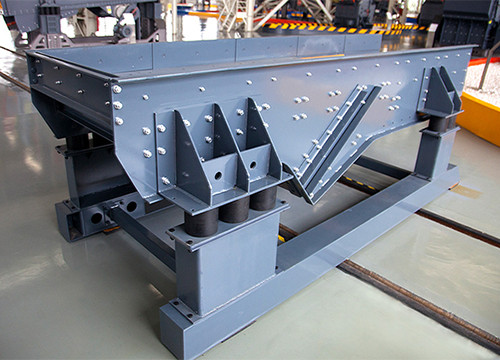

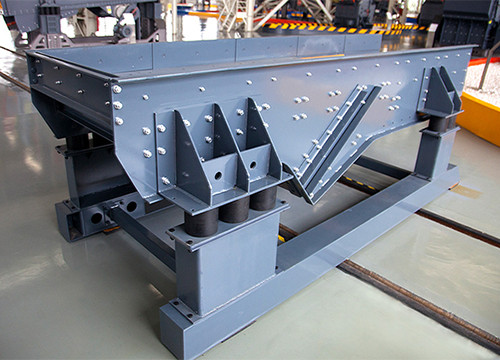

2023年3月10日After crushing and grinding, a vibration screen with a size of fewer than 80 meshes was used to collect the bauxite. Chemical analysis of the major elements (Al, Si, Fe, Ti, and Ca) was performed using x-ray fluorescence spectroscopy (XRF). and the aluminum oxide in the raw material of the bauxite mine was the actual digestion

Studies on Batch Grinding of Bauxite Ore in Ball Mill

In the present study bauxite ore of hardness 1-3, specific gravity 2-2.5 has been taken for grinding tests in a ball mill. The experiments were conducted for three feed (ore) sizes (i.e. -1/2 + 3/8", -3/8 + ¼,-1/4 + 3/16 ) and three ball sizes (i.e. 1,1/2,3/4 ). It is now an established fact that the size of fineness by some grinding

Physical Bauxite Processing: Crushing and Grinding of Bauxite

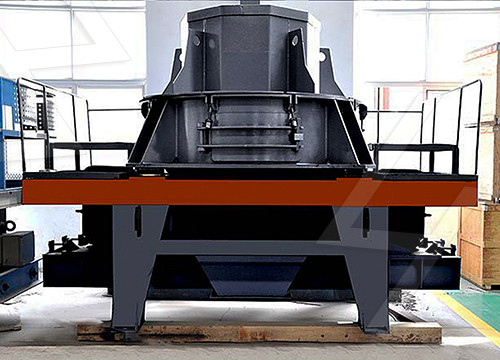

acteristics of the raw bauxite and the capacity rates required. Typical crusher types evaluated for a specific project include Jaw Crushers, Cone Crushers, high-speed Crushing and Grinding of Bauxite 135 and Boehmitic bauxites are typically 1–3, while it ranges from 6½–7 for Diasporic

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日Download Citation Physical Bauxite Processing: Crushing and Grinding of Bauxite The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that

Grinding Behavior and Potential Beneficiation

2020年3月31日This laboratory study investigates selective grinding and beneficiation options for a Greek bauxite ore. First, a series of batch grinding tests were carried out in order to investigate the grinding

Bauxite raw material processing complex (2019) Loginova Irina

FIELD: metallurgy.SUBSTANCE: technical solution relates to non-ferrous metallurgy, particularly, to production of alumina from bauxites. Complex for bauxite raw material processing comprises two lines, in the first of which there is a crusher for crushing high-quality bauxite, mill for bauxite grinding in recycled solution, autoclave for high

CNA Low-quality raw bauxite ore open-grinding

2013年10月19日1. a low-grade bauxite raw ore open-circuit grinding ore-dressing technique, is characterized in that it includes raw ore open-circuit grinding cyclone classification machine technique...

Metals Free Full-Text Effective Extraction of Vanadium from Bauxite

A new bauxite-type vanadium ore with a grade of 0.96% V2O5 was found in Hanzhong, China, having quartz, illite, and calcite as the main mineral constituents and vanadium that mainly occurs in the aluminosilicate lattice of illite by replacing Al3+ with V3+ in isomorphism form. In this study, a novel process of low-temperature sulfating roasting–water leaching

SEM photos of reduction-grinding products obtained at different

Download scientific diagram SEM photos of reduction-grinding products obtained at different reduction temperature. from publication: Study on Metallized Reduction and Magnetic Separation of Iron

Raw material grinding plants Manfredini and Schianchi

ManfrediniSchianchi, a leading company in the treatment of raw materials, has been proposing targeted and flexible solutions for the grinding of countless types of materials. In ManfrediniSchianchi every problem of Grinding proposed to us by our customers is always previously analyzed by our technical team and by ours research laboratory

Grinding Of Raw Bauxite

The grinding behavior of the bauxite ore was evaluated by identifying the relationship between the remaining mass (%) fraction of each particle size vs. grinding time. Figure 5a shows, as an example, the experimental data obtained for four selected sizes, namely 0.600, 0.300, 0.150 and 0.075 mm when the material filling volume (f c) was 5%.

Bauxite Calcination Plant by Rotary Kiln with Fine Grinding

Bauxite Calcination Plant by Rotary Kiln with Fine Grinding Ball Mill. Refractory Grade Calcined Bauxite Calcined bauxite is produced by sintering/calcining of low iron, low alkali containing raw bauxites at temperatures of 1600 1800 degree Celsius. In this calcination process the high refractory mineral phase’s corundum and mullite are formed.

Desulfurization by Adding Sodium Nitrate in the Production of

2023年3月10日After crushing and grinding, a vibration screen with a size of fewer than 80 meshes was used to collect the bauxite. Chemical analysis of the major elements (Al, Si, Fe, Ti, and Ca) was performed using x-ray fluorescence spectroscopy (XRF). and the aluminum oxide in the raw material of the bauxite mine was the actual digestion

1250 mesh bauxite grinding mill Popular 1250 mesh bauxite grinding

Vertical Bauxite Grinding Mill Raw Mill Cement Plant 325 1250 Mesh...1250 Mesh High Efficiency Vertical Bauxite Grinding Mill Machine Description The vertical grinding mill is widely used in such small and medium industries as mining, chemicals, building materials, metallurgy, refractories, pharmaceuticals, cement, etc.

Studies on Batch Grinding of Bauxite Ore in Ball Mill

In the present study bauxite ore of hardness 1-3, specific gravity 2-2.5 has been taken for grinding tests in a ball mill. The experiments were conducted for three feed (ore) sizes (i.e. -1/2 + 3/8", -3/8 + ¼,-1/4 + 3/16 ) and three ball sizes (i.e. 1,1/2,3/4 ). It is now an established fact that the size of fineness by some grinding