Copper Mining Process Plant

Copper-processing technologies: Growing global copper

2023年2月17日Primary sulfides are typically processed at plants using flotation-based systems. Flotation is generally economical for ores with levels of copper that are greater than 0.25 percent, 5 from which flotation can recover 85 to 90 percent. Ores lower than

Copper Mining and Processing: Processing Copper Ores Superfund

A. Processing of Oxide OreB. Processing of Sulfide OreC. Recycling Copper

Oxide ores are generally processed using hydrometallurgy. This process uses aqueous (water-based) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning. Heap Leachingis the process of using percolating 在superfund.arizona.edu上查看更多信息预计阅读时间:8 分钟

Copper processing Definition, History,Facts Britannica

根据热度为您推荐•反馈

Copper Mining and Processing: Everything you Need to

The Copper Mining Process Once it’s located within the earth, copper ore goes through eight stages before the consumer sees it in various products that affect every day life in

Copper processing Ores Britannica

copper mine For lower-grade deposits located near the surface, the open-pit method is the most practical for the mining of large tonnages of material. Large track-mounted drills prepare the ore for blasting, and the broken

Copper extraction Wikipedia

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical

Copper MiningExtraction Process Flow Chart

2015年8月26日Copper MiningExtraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process.

SX-EW (solvent extraction and electrowinning) KGHM Corporate

SX-EW technology involves leaching (the process of dissolving useful ingredients with a solution) in atmospheric conditions of copper ore heaps by means of diluted sulphuric

Copper Production: How Is Copper Made? ThoughtCo

2019年9月26日The remaining mixture is a molten copper sulfide referred to as matte. The next step in the refining process is to oxidize liquid matte in order to remove iron to burn

Copper Producers Have Agreed to Clean up Operations

1 The electricity that mining companies like Freeport-McMoRan, BHP, and Rio Tinto use at plants that process ore into copper are the industry's largest source of

Copper processing Definition, History,Facts

copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products. samovar In its pure form or as an alloy, copper (Cu) is one of

Newmont Corporation About Us About Mining The Mining Process

The Mining Process Our mission is to transform mineral resources into shared value for our stakeholders and lead the industry in shareholder returns, safety, social responsibility and environmental stewardship. The Mining Process Finding new mineral reserves is critical to the success of our company.

SX-EW (solvent extraction and electrowinning) KGHM Corporate

SX-EW (solvent extraction-electrowinning) is the cathode copper production technology used in the KGHM International facilities. SX-EW technology involves leaching (the process of dissolving useful ingredients with a solution) in atmospheric conditions of copper ore heaps by means of diluted sulphuric acid.

Copper Producers Have Agreed to Clean up Operations and Cut

1 The electricity that mining companies like Freeport-McMoRan, BHP, and Rio Tinto use at plants that process ore into copper are the industry's largest source of emissions, according to the

KAZ Minerals Focused on copper

The copper mining process. KAZ Minerals operates six producing mines. The three mines in East Region are underground while the Bozshakol, Aktogay and Bozymchak mines are open pit. The mines generally

Copper Processing Equipment, Process Flow, Cases JXSC

2019年8月23日According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore, containing less than 10% copper oxide; oxidized ore, containing more than 30% copper oxide; mixed ore, containing 10% to 30% of copper oxide. Copper sulfide ore flotation

The Basics of How Ore Processing and Recovery

2018年3月15日Savona Equipment. 24 Followers. Savona Equipment Ltd. is a Canadian Mining and Milling Equipment Supply Company backed by over 100 years of experience.

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation

Xinhai Mining Appears at PDAC Global Mining Conference in Canada 2023-03-10; Different Factors on Flotation Efficiency of Chalcopyrite Copper Ore and Pyrite 2023-03-08; Xinhai devotes to providing “Turn-key Solutions for Mineral Processing Plant (EPC+M+O)”, namely “design and research complete equipment manufacturing and

Copper Beneficiation Mineral Processing Plant chinax

China Copper Beneficiation Mineral Processing Plant, Find details about China Mineral Processing Plant from Copper Beneficiation Mineral Processing Plant Zhengzhou Hengyang Industry Co., Ltd.

copper oxide ore processing plant,copper mining process

folkd_mining_equipment saved and folkd this page on 05/24/2012 12:56am. copper oxide ore processing plant mining manufacturer and mistributor

Copper Processing Plant Prominer (Shanghai)

I. Physical processing technology: II. Chemical processing technology: 1. Flotation process are widely used for copper extraction. The ore pulp slurry is pumped to flotation cells for extracting. The flotation cells are divided

Copper Ore Processing Methods Metallurgist

2017年4月11日Flotation, when first introduced between 1913 and 1916, was used primarily to reduce losses of copper in the fine tailings of gravity plants. From an accessory to gravity methods, flotation very rapidly

The use of solar energy in the copper mining processes

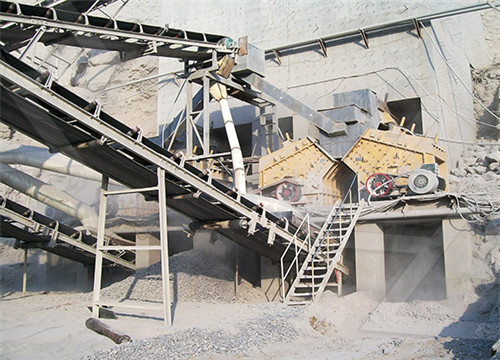

2021年10月1日Copper mineral processing plants Copper ore is extracted from the mine and a first size reduction stage is used to transport the ore for further processing. Pyro-metallurgical and hydrometallurgical processes are used to treat copper ores. As Fig. 2 shows, in the pyro-metallurgy process, copper-sulfide ores are ground to liberate Cu

Copper Production: How Is Copper Made? ThoughtCo

2019年9月26日The remaining mixture is a molten copper sulfide referred to as matte. The next step in the refining process is to oxidize liquid matte in order to remove iron to burn off sulfide content as sulfur dioxide. The result is 97-99%, blister copper. The term blister copper comes from the bubbles produced by sulfur dioxide on the surface of the copper.

Kennecott Rio Tinto

Our Kennecott mine is a world-class, integrated copper mining operation located just outside Salt Lake City, Utah, in the United States. Kennecott has been mining and processing minerals from the rich ore body of the

First Quantum Minerals Ltd. Our Operations

The process plant is designed to treat 55 million tonnes per annum of copper ore from Sentinel mine, with a separate 4 million tonnes per annum circuit designed to process nickel ore feed from the Enterprise project or additional copper ore feed from Sentinel. Mining and Processing. The Taca Taca copper-gold-molybdenum porphyry deposit is

Copper Production: How Is Copper Made? ThoughtCo

2019年9月26日The remaining mixture is a molten copper sulfide referred to as matte. The next step in the refining process is to oxidize liquid matte in order to remove iron to burn off sulfide content as sulfur dioxide. The result is 97-99%, blister copper. The term blister copper comes from the bubbles produced by sulfur dioxide on the surface of the copper.

Copper Producers Have Agreed to Clean up Operations and Cut

1 The electricity that mining companies like Freeport-McMoRan, BHP, and Rio Tinto use at plants that process ore into copper are the industry's largest source of emissions, according to the

KAZ Minerals Focused on copper

The copper mining process KAZ Minerals operates six producing mines. The three mines in East Region are underground while the Bozshakol, Aktogay and Bozymchak mines are open pit. The mines generally

Copper Ore Processing Methods Metallurgist

2017年4月11日Flotation, when first introduced between 1913 and 1916, was used primarily to reduce losses of copper in the fine tailings of gravity plants. From an accessory to gravity methods, flotation very rapidly

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation

Xinhai Mining Appears at PDAC Global Mining Conference in Canada 2023-03-10; Different Factors on Flotation Efficiency of Chalcopyrite Copper Ore and Pyrite 2023-03-08; Xinhai devotes to providing “Turn-key Solutions for Mineral Processing Plant (EPC+M+O)”, namely “design and research complete equipment manufacturing and

The Basics of How Ore Processing and Recovery

2018年3月15日Savona Equipment. 24 Followers. Savona Equipment Ltd. is a Canadian Mining and Milling Equipment Supply Company backed by over 100 years of experience.

Copper Beneficiation Mineral Processing Plant chinax

China Copper Beneficiation Mineral Processing Plant, Find details about China Mineral Processing Plant from Copper Beneficiation Mineral Processing Plant Zhengzhou Hengyang Industry Co., Ltd.

copper oxide ore processing plant,copper mining process

folkd_mining_equipment saved and folkd this page on 05/24/2012 12:56am. copper oxide ore processing plant mining manufacturer and mistributor

Copper mines becoming more capital-intensive and costly to run

2022年7月20日The world’s largest porphyry copper mine in China started production in December, 2021. Owner Zijin Mining expects to produce 120-130,000 tonnes of copper this year after a first phase is completed. Total capex of around $1.7 billion leaves a capex cost per tonne of production at $13,769 ($1.79B/130,000t) Oyu Tolgoi.

Copper Processing Plant Prominer (Shanghai) Mining Technology Co.,Ltd.

Copper Processing Plant description: There are mainly three types of copper ore: sulfide type copper ore, oxide type copper ore and mixed ore. Based on abundant experiences on copper mining project, Prominer supplies customized solution for different types of copper ore. General processing technologies for copper ore are summarized as below:

The use of solar energy in the copper mining processes

2021年10月1日Copper mineral processing plants Copper ore is extracted from the mine and a first size reduction stage is used to transport the ore for further processing. Pyro-metallurgical and hydrometallurgical processes are used to treat copper ores. As Fig. 2 shows, in the pyro-metallurgy process, copper-sulfide ores are ground to liberate Cu

Mine construction cost: how much does it cost to build a mine or

In the case of the construction of mines, quarries, processing plants and other mining enterprises, this usually means hundreds of millions of euros of loans and investments that must be attracted many years before the project will generate stable cash flows. But over this long period, engineers had to move from mining copper near the