Adjustable For Easy Wear Parts! Shaft Impact Mining Mill

Spare and Wear Parts Metso Outotec

Rely on experts because not all parts are created equal. Spare and wear parts built to perform. Hide filters. Industry. Aggregates. Metals refining. Mining. Process mining and

Impact Crusher Parts Amsted Global Solutions

We offer a wide range of impact crusher parts to meet the requirements of your specific application, sourced from OEMs you know and trust. Available for horizontal shaft

Wear parts for mining

Sunwill is supplying in the mining industry with following wear parts and wear solutions: 1, Impact crusher wear parts include blow bars, impact plates, wear liners and other

Crusher Wear Parts For Jaw, Cone, Impact, VSI, and

Qiming Machinery manufactures a huge stock inventory of premium quality compatible spare parts and wear parts to suit a popular range of vertical shaft impactors (VSI). Available

Horizontal Shaft Impactor Parts I Mining Wear Parts

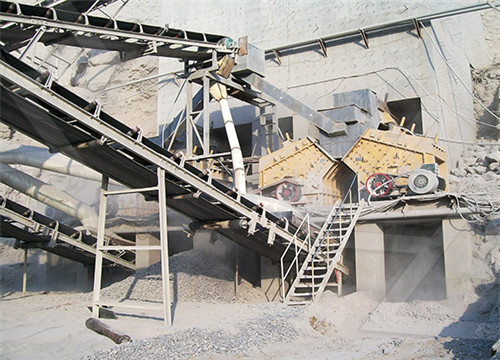

A Horizontal Shaft Impactor (HSI) crusher operates on a different principle to a VSI whereby the rock is fed onto the outside of the rotor which is spinning on a horizontal axis shaft.

Routine Hammer Mill Maintenance

2016年10月27日Hammers. Depending on the application, hammers will be either 2-way or 4-way reversible, indicating the number of rotations possible before replacing.

Hammer Mill Crusher Wear Parts Sandrock Mining

Hammer Mill Crusher Wear Parts Sandrock Mining Hammer Mill Crusher Wear Parts +86-157-9771-7019 Contact NOW! Hammer Mill Crusher Wear Parts Common alias:

Hammer Mill Crusher Wear Parts Wear Spare Parts Gdoo Mining

Ball mill is typically designed for grinding different kinds of ores and many other grindable materials, and it can be widely used in mining fields, building materials, metallurgy,

Crusher Manganese Parts Wear Spare Parts Gdoo Mining

Hammer Mill Crusher Wear Parts. Impact Crusher Parts. Converyor Accessories. Conveyor Belt. Conveyor Rollers. Gearbox. V-Belt. Gdoo Mining is a growing

® NP Series™ impact crushers Metso Outotec

High performance. ® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs. ® NP™ crushers have a unique blow bar attachment system.

KenCast Wear Protection Products Kennametal

KenCast wear parts are proven to withstand extreme abrasive and high-impact applications. KenCast is extremely versatile and can fit nearly any machine for nearly any application. It is easily welded or attached mechanically into position. What is KenCast?

Blow Bars OEM Interchangeable Impactor Wear Parts GTEK

GTEK® offers different designs and manufactures various solutions of blow bar for an extensive range of OEM horizontal impact crusher brands including: Hazemag, Mesto, mpl, Rockster, Rubble Master, , Striker, Keestrack, McClosky, Eagle, Tesab, Finlay and others. GTEK® "Genuine Alternative" blow bars are designed to

Impact Crusher Parts Wear Parts For Industry Qiming Casting

When it comes to Replacement Impact Crusher Parts, Qiming Casting has been crushing the market for decades. If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed, and warranted replacement parts for your cone crusher. Qiming Casting can supply impact crusher wear parts with the best quality and suitable price.

Tungsten Carbide Wear Parts KoneCarbide

KoneCarbide manufactures high-quality wear parts made from tungsten carbide, featuring high heat, corrosion, and wear resistance, thus improving the service life of machinery. Over the past few years, we worked closely with customers on product quality, earning wide recognition. Categories Vertical Shaft Impact Crusher (VSI) Rotor and Wear Parts

Crusher Wear Parts For Jaw, Cone, Impact, VSI, and Gyratory

Qiming Machinery manufactures a huge stock inventory of premium quality compatible spare parts and wear parts to suit a popular range of vertical shaft impactors (VSI). Available for aggregates, cement, and mining industries, parts designed to improve efficiency and reduce costs by extending wear life and minimizing downtime.

Mill liners Metso Outotec

With our integrated approach, we make sure that your different wear parts work together to help you achieve your production and sustainability goals. 1. Head linings 2. Shell linings 3. Discharge systems 4. Trunnion linings 5. Trommel screens Head linings

5 Horizontal Grinder Wear Parts to Inspect Regularly

2021年6月28日Some anvils are adjustable, and as the edge wears, it may need to be repositioned closer to the mill. When to replace: When the anvil appears to be dull, the hard facing is worn off, or it is wearing thin, it’s time to replace or rebuild this grinder wear part.

Routine Hammer Mill Maintenance

2016年10月27日Hammers. Depending on the application, hammers will be either 2-way or 4-way reversible, indicating the number of rotations possible before replacing. Hammers should be rotated when the cutting edge is well rounded and the machine is not at top efficiency. Hammers should always be replaced in factory balanced sets.

Hammer Mill Crusher Wear Parts Sandrock Mining

Hammer Mill Crusher Wear Parts Sandrock Mining Hammer Mill Crusher Wear Parts +86-157-9771-7019 Contact NOW! Hammer Mill Crusher Wear Parts Common alias: high chrome hammer, high chrome hammer, high manganese steel hammer, hard alloy steel hammer, counterattack broken hammer, double liquid bimetal composite hammer

Qiming Casting-China’s wear-resistant casting industry leader

Qiming Casting is able to produce and deliver suitable quality crusher replacements and worn parts at extremely low costs for all major mobile crushing and screening equipment thanks to the hiring of highly experienced people. Our success in the quarry and mining industries has been attributed to our emphasis on excellent craftsmanship, cost

Hammer Mill Crusher Wear Parts Wear Spare Parts Gdoo Mining

Application. Ball mill is typically designed for grinding different kinds of ores and many other grindable materials, and it can be widely used in mining fields, building materials, metallurgy, chemical industry, and many other industries. Ball mill spare parts need has sufficient strength, high wear resistance, and good processability.

Crusher Manganese Parts Wear Spare Parts Gdoo Mining

Hammer Mill Crusher Wear Parts. Impact Crusher Parts. Converyor Accessories. Conveyor Belt. Conveyor Rollers. Gearbox. V-Belt. Gdoo Mining is a growing company with years of experience in produce and supply of wear parts such as the Bowl Liner, Mantle, Jaw Plate, Cheek Plate, Hammer, Frame, Linerand spare parts such as

VSI Rotor and Wear Parts KoneCarbide

KoneCarbide supplies the complete set of rotor and wear parts for the VSI sand-making machine, containing: Upper Wear Plate (3 pieces) Lower Wear Plate (3 pieces) 488.0368 Back-Up Tip (3 pieces) 488.1456 Rotor Tip (9 pieces) 448.1644/1703/1704 Tip/Cavity Wear Plate (9 pieces) 488.0362 Trail Plate (2 pieces) Feed Eye Ring (1 piece)

Qiming Casting-China’s wear-resistant casting industry

Qiming Casting is able to produce and deliver suitable quality crusher replacements and worn parts at extremely low costs for all major mobile crushing and screening equipment thanks to the hiring of highly

Impact Crusher Parts Wear Parts For Industry

When it comes to Replacement Impact Crusher Parts, Qiming Casting has been crushing the market for decades. If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed, and warranted

Blow Bars OEM Interchangeable Impactor Wear Parts GTEK

GTEK® offers different designs and manufactures various solutions of blow bar for an extensive range of OEM horizontal impact crusher brands including: Hazemag, Mesto, mpl, Rockster, Rubble Master, , Striker, Keestrack, McClosky, Eagle, Tesab, Finlay and others. GTEK® "Genuine Alternative" blow bars are designed to

Horizontal Shaft Impactor Parts I Mining Wear Parts

A Horizontal Shaft Impactor (HSI) crusher operates on a different principle to a VSI whereby the rock is fed onto the outside of the rotor which is spinning on a horizontal axis shaft. There are usually 2 or 3 adjustable curtains or Aprons that control the product particle size as they pass from chamber to chamber and ultimately exit the

Vertical Roller Mills

spare parts, including wear segments, and we provide all aftersales services to help you get the most out of your vertical roller mill throughout its lifetime. online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high

5 Horizontal Grinder Wear Parts to Inspect Regularly

2021年6月28日Some anvils are adjustable, and as the edge wears, it may need to be repositioned closer to the mill. When to replace: When the anvil appears to be dull, the hard facing is worn off, or it is wearing thin, it’s time to replace or rebuild this grinder wear part.

Crusher Manganese Parts Wear Spare Parts Gdoo Mining

Hammer Mill Crusher Wear Parts. Impact Crusher Parts. Converyor Accessories. Conveyor Belt. Conveyor Rollers. Gearbox. V-Belt. Gdoo Mining is a growing company with years of experience in produce and supply of wear parts such as the Bowl Liner, Mantle, Jaw Plate, Cheek Plate, Hammer, Frame, Linerand spare parts such as

Routine Hammer Mill Maintenance

2016年10月27日Hammers. Depending on the application, hammers will be either 2-way or 4-way reversible, indicating the number of rotations possible before replacing. Hammers should be rotated when the cutting edge is well rounded and the machine is not at top efficiency. Hammers should always be replaced in factory balanced sets.

Hammer Mill Crusher Wear Parts Wear Spare Parts Gdoo Mining

Ball mill is typically designed for grinding different kinds of ores and many other grindable materials, and it can be widely used in mining fields, building materials, metallurgy, chemical industry, and many other industries. Ball mill spare parts need has sufficient strength, high wear resistance, and good processability.

Hammer Mill Crusher Wear Parts Sandrock Mining

Hammer Mill Crusher Wear Parts Sandrock Mining Hammer Mill Crusher Wear Parts +86-157-9771-7019 Contact NOW! Hammer Mill Crusher Wear Parts Common alias: high chrome hammer, high chrome hammer, high manganese steel hammer, hard alloy steel hammer, counterattack broken hammer, double liquid bimetal composite hammer

Gold Ore Rock Crusher Impact Flail Processing Quartz Crushing Mill

Gold Stryker® GS-7000-LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker® GS-7000-LDuses a large 25 HP Honda Industrial engine for many years of trouble free use. It can process and crush up to 7 tons in a day, all the way down to #300 mesh through the mill

Crusher Wear Parts Amsted Global Solutions

Delivering a crushing performance. Wear parts from Amsted Global Solutions help keep your crusher working at peak performance. We produce crusher wear parts and castings for all your aggregate and mining needs. We design, manufacture and source products to your exact specifications and applications.

VSI Rotor and Wear Parts KoneCarbide

KoneCarbide supplies the complete set of rotor and wear parts for the VSI sand-making machine, containing: Upper Wear Plate (3 pieces) Lower Wear Plate (3 pieces) 488.0368 Back-Up Tip (3 pieces) 488.1456 Rotor Tip (9 pieces) 448.1644/1703/1704 Tip/Cavity Wear Plate (9 pieces) 488.0362 Trail Plate (2 pieces) Feed Eye Ring (1 piece)

Crusher and Grinding Mill Wear Parts Information GlobalSpec

Crusher liners may be used with cone, jaw, roll, gyratory or horizontal shaft impact crushers. They are also used with hammermills. Function and thickness are important specifications to consider when selecting crusher and grinding mill wear parts. Some products are designed to provide protection against abrasive, low-impact, or sliding wear.