Air-Swept Coal Mill In Thermal Power Plant

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1. Comminution (size reduction); 2. Drying; 3. Transport of material; 4. Classification.

Coal mill pulverizer in thermal power plants SlideShare

2012年11月17日COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY 2. 1.Introduction Coal continues to

Air-Swept Coal Mill Of High Quality Fote Machinery

Air swept coal mill is widely used in cement industry, thermal power generation industry, metallurgical industry, chemical industry, gold industry and other industries. 6.1 Air-swept coal mill in cement plants At

Air swept coal mill Geckointech

ApplicationStructureWorking PrincipleAdvantagesAir swept coal mill, or air swept pulverizer, is major grinding equipment for pulverized coal production in power plant, cement plant. Hot air stream (heated by air preheater) from primary air fan could take away pulverized coal when passing through coal mill, and dry the fine particles at the same time. Air swept coal mill is low speed ball mill w...

Coal Drying Improves Performance and Reduces

excess air. Station service power will decrease with drier coal due to a decrease in fan power and mill power. The combination of all these effects caused by firing drier coal

MRHS Mill Reject Handling System in Thermal Power Plant

2021年5月20日System Description of MRHS. Mill reject handling system (MRHS) consist of Following sub system or equipment: 1. Conveying Air System. Conveying air compressor will located in plant compressor

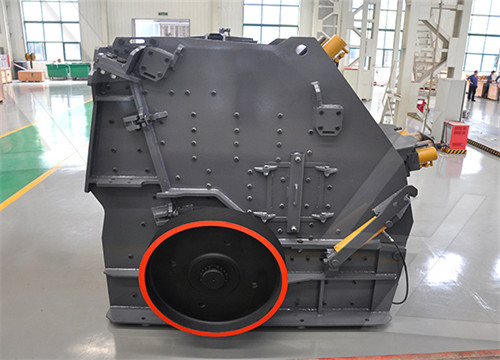

Coal Mill In Cement Plant, Air-swept Coal Mill Coal Mill

Air-swept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

2021年8月5日Introduction The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder

Coal Mill in Cement Plant Vertical Roller MillAir

Air-Swept Ball Mill The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement

A new model-based approach for power plant Tube-ball mill

2014年4月1日These have impacted the coal mill and power plant operation safety and reliability. The Vertical Spindle mill model was developed through the authors’ work before 2007. Thermal process analysis. Hot air is swept through the mill by two variable speed fans, and the air acts as both the drying and transporting agent for the coal.

Raymond® Roller Mill air-swept vertical ring-roll Schenck Process

The Raymond® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately. ½ -2in / 10-50mm, the roller mill can produce

NUMERICAL AND EXPERIMENTAL INVESTIGATION OF A

Abstract: In a pulverized coal-fired (PCF) thermal power plant (TPP), mixture of coal, air and gas is supplied into the furnace volume via the mill duct system and coal/air distribution should ideally be maintained as homogeneous as possible to ensure an efficient combustion. The phenomenon of coal/air flow in the mill duct system has been so far

Coal mill pulverizer in thermal power plants

2012年11月17日COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY 2. 1.Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large

Air swept coal mill Geckointech

Air swept coal mill, or air swept pulverizer, is major grinding equipment for pulverized coal production in power plant, cement plant. Hot air stream (heated by air preheater) from primary air fan could take away pulverized coal when passing through coal mill, and dry the fine particles at the same time. Air swept coal mill is low speed ball

Coal Drying Improves Performance and Reduces Emissions

excess air. Station service power will decrease with drier coal due to a decrease in fan power and mill power. The combination of all these effects caused by firing drier coal will result in an improvement in boiler efficiency and unit heat rate, primarily due to the lower stack loss and lower station service power.

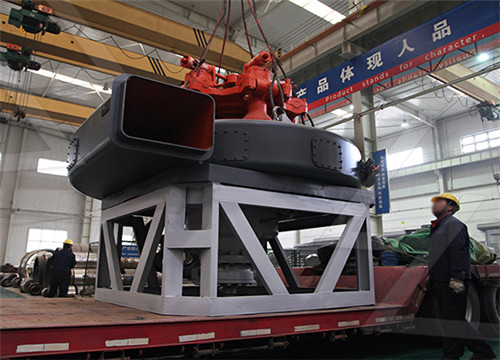

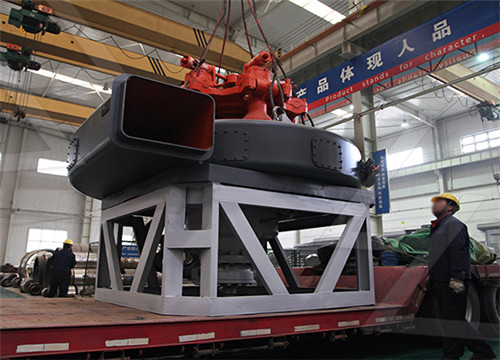

Air-Swept Coal Mill-FTM Machinery chinaftm

Coal Mill is the main equipment of the rotary kiln cement clinker production system and at the same time, it is also suitable for powder grinding equipment system in such industries as thermal power plant,

MRHS Mill Reject Handling System in Thermal

2021年5月20日System Description of MRHS. Mill reject handling system (MRHS) consist of Following sub system or equipment: 1. Conveying Air System. Conveying air compressor will located in plant compressor

Coal Mills in Thermal Power Plant PDF Mill (Grinding) Scribd

COAL ON DRY BASIS: 1.ANTHRACITE 2.BITUMINOUS 3.SUB-BITUMINOUS 4.LIGNITE fPULVERISED FORM OF COAL IT HAS MADE MODERN STEAM GENERATING UNITS HIGHLY THERMAL EFFICIENT, RELIABLE AND SAFE. IT HAS MADE EFFICIENT USE OF LOW GRADE COALS. IT PROVIDES GOOD CONTROL OVER COAL AIR

sbmchina/sbm coal powder grinding media equipment.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Air Swept Ball Mill Great Wall

The Air swept ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and

Pulverizers 101: Part I POWER Magazine

2011年8月1日Our experience with both RP and MPS pulverizers has been that mills designed for a throughput of about 120,000 pounds of coal per hour, an HGI of about 45 to 50, and coal fineness exceeding 75%

NOx Control Technologies for Thermal Power Stations

After the primary combustion zone, the air required to complete combustion of coal is added (see Figure 2: Layout of LNB, OFA and SNCR system in a pulverized coal power plant). This staging reduces peak flame temperatures resulting in lower NO x formation. NOx Control Technologies for Thermal Power Stations Factsheetdd 3 27/07/18 5:03 PM

Optimized fluegas denitrification control strategy to enhance SCR

In China, the Emission Standards of Air Pollutants for Thermal Power Plants issued in 2011 clearly requires controlling the daily average of NO x emissions from coal-fired units to less than 100 mg m −3 [3], and ultralow emission regulations require the daily average of NO x emission to be less than 50 mg m −3 [4].

A new model-based approach for power plant Tube-ball mill

2014年4月1日These have impacted the coal mill and power plant operation safety and reliability. The Vertical Spindle mill model was developed through the authors’ work before 2007. Thermal process analysis. Hot air is swept through the mill by two variable speed fans, and the air acts as both the drying and transporting agent for the coal.

Raymond® Roller Mill air-swept vertical ring-roll Schenck Process

The Raymond® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately. ½ -2in / 10-50mm, the roller mill can produce

NUMERICAL AND EXPERIMENTAL INVESTIGATION OF A

Abstract: In a pulverized coal-fired (PCF) thermal power plant (TPP), mixture of coal, air and gas is supplied into the furnace volume via the mill duct system and coal/air distribution should ideally be maintained as homogeneous as possible to ensure an efficient combustion. The phenomenon of coal/air flow in the mill duct system has been so far

Air swept coal mill Geckointech

Air swept coal mill, or air swept pulverizer, is major grinding equipment for pulverized coal production in power plant, cement plant. Hot air stream (heated by air preheater) from primary air fan could take away pulverized coal when passing through coal mill, and dry the fine particles at the same time. Air swept coal mill is low speed ball

Air-Swept Coal Mill-FTM Machinery chinaftm

Coal Mill is the main equipment of the rotary kiln cement clinker production system and at the same time, it is also suitable for powder grinding equipment system in such industries as thermal power plant,

Coal Drying Improves Performance and Reduces Emissions

excess air. Station service power will decrease with drier coal due to a decrease in fan power and mill power. The combination of all these effects caused by firing drier coal will result in an improvement in boiler efficiency and unit heat rate, primarily due to the lower stack loss and lower station service power.

MRHS Mill Reject Handling System in Thermal

2021年5月20日System Description of MRHS. Mill reject handling system (MRHS) consist of Following sub system or equipment: 1. Conveying Air System. Conveying air compressor will located in plant compressor

Coal Mills in Thermal Power Plant PDF Mill (Grinding) Scribd

COAL ON DRY BASIS: 1.ANTHRACITE 2.BITUMINOUS 3.SUB-BITUMINOUS 4.LIGNITE fPULVERISED FORM OF COAL IT HAS MADE MODERN STEAM GENERATING UNITS HIGHLY THERMAL EFFICIENT, RELIABLE AND SAFE. IT HAS MADE EFFICIENT USE OF LOW GRADE COALS. IT PROVIDES GOOD CONTROL OVER COAL AIR

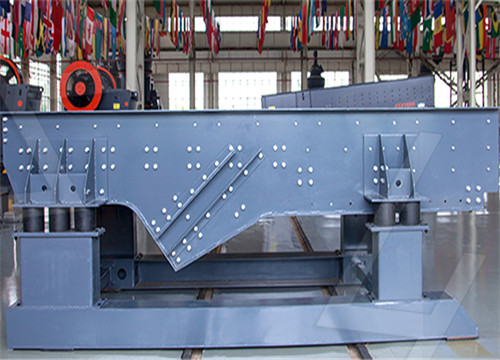

Air-swept Coal Mill Cement Plant Equipment ETW International

Air-swept coal mill is a kind of cement equipment used to dry and grind coal. This coal grinding mill can be used in cement plants, power plants, etc. Our air-swept coal mill is mainly made up of feeding device, main bearing, rotation device, discharging device, lubricating system, and electric control system. The hot air and raw coal enter the

Air Swept Mill Mineral ProcessingMetallurgy

2017年5月25日The “air-swept” method of operation of a mill eliminates the conveyor system which was often used in earlier types of plant to transport the product to the classifier and the oversize material from the

Pulverizers 101: Part I POWER Magazine

2011年8月1日Our experience with both RP and MPS pulverizers has been that mills designed for a throughput of about 120,000 pounds of coal per hour, an HGI of about 45 to 50, and coal fineness exceeding 75%

sbmchina/sbm coal powder grinding media equipment.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Coal Handling Plant In Thermal Power Plant

2016年11月13日The initial process in coal based thermal power plant is coal handling.The Function of coal Handling Plant in thermal power plant is to receive,process, store, feed the coal bunkers consistently over entire life of the power plant. Coal is transported in thermal power station either by railways,roadways or rope ways.

Thermal Power: Guidelines for New Plants IFC

based thermal power plants with a capacity of 50 or more megawatts of electricity (MWe) that use coal, fuel oil, or natural gas. 1 Conventional steam-producing thermal power plants generate electricity through a series of en-ergy conversion stages: fuel is burned in boilers to convert water to high-pressure steam, which is