Part Of The Jaw Crushing Equipment Pdf

® C Series™ jaw crushers Proven reliability

aspect when considering the performance of a jaw crusher. Our industry-leading stroke is amplified from top to bottom, being at its longest in the lower parts of the cavity. This

Jaw Crusher Series Technical Specification Mining

Jaw Crusher Series Technical Specification Mining Equipment, Parts

Metso ® C Series™ jaw parts

maximize on the life of the wear parts, the crusher cavity should be full. • The feed must be distributed evenly across the crushing chamber. 3. Apply proper scalping • Fines

Industrial Solutions Jaw crushers ThyssenKrupp

on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system

Jaw Crusher ComponentsParts Mineral Processing

2015年7月24日The first component of the crusher is the drive motor. This will drive a reducer sheave that is attached to an eccentric shaft. On the other end of the shaft is the flywheel. The purpose of the flywheel is to

Design and Construction of Rock Crushing Machine from

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the

Jaw Crushers JW Series

MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155-480 (140-435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder The only warranty applicable to our equipment is the standard written warranty applicable to the particular product and sale, and makes no other warranty

® C Series™ jaw crushers Proven reliability and

aspect when considering the performance of a jaw crusher. Our industry-leading stroke is amplified from top to bottom, being at its longest in the lower parts of the cavity. This increases the open area between the jaw dies allowing the material to have more space to get out, while also enabling inter-particle crushing. This design principle

Industrial Solutions Jaw crushers ThyssenKrupp

on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw crusher with the same feed opening. The diversity of feed mate -

Metso ® C Series™ jaw parts

maximize on the life of the wear parts, the crusher cavity should be full. • The feed must be distributed evenly across the crushing chamber. 3. Apply proper scalping • Fines (material smaller then CSS) should be removed from the feed material. This is done by the grizzly bar section of the feeder. Fines in the jaw crusher increase

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017年6月30日A pitman of a jaw crusher has an upper part, which includes an upper supporting point for supporting the pitman in the body of the jaw crusher, and a lower part having a lower supporting point for

Design and Construction of Rock Crushing Machine from

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

Jaw Crusher ComponentsParts Mineral

2015年7月24日The first component of the crusher is the drive motor. This will drive a reducer sheave that is attached to an eccentric shaft. On the other end of the shaft is the flywheel. The purpose of the flywheel is to

(PDF) Material Selection for Crusher Jaw in a Jaw

2015年11月9日18 Adelana Rasaki Adetunji et al.: Material Selection for Crusher Jaw in a Jaw Crusher Equipment adopted for various designs (Chan and Zhou, 199 4 and Dieter, 1991) .

Cost Analysis for Crushing and Screening Part II CORE

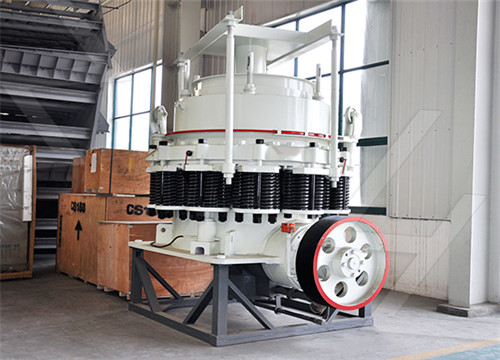

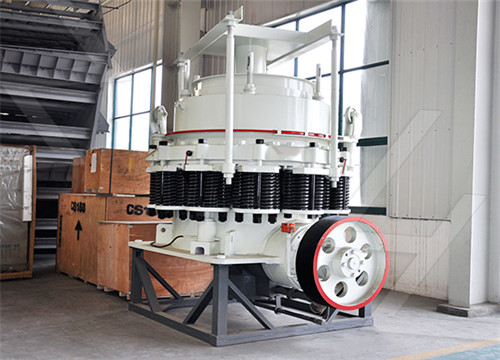

production is concentrated to jaw crushers and cone crushers. 1.1.3.2 Process Flow The process flow described in figure.. is a typical process flow built up by a primary crushing stage, secondary crushing stage. The primary stage usually has a jaw or a gyratory crusher and screening equipment.

EQUIPMENT AND MAINTENANCE

result of joint efforts on the part of operators and manufac turers. During normal crushing, two factors can lead to the destruction of expensive crusher parts; the introduction of an uncrushable item, e.g. tramp iron or mine timbers, and a phenomenon called packing. This is caused when a large amount of fines enters the crushing chamber and

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

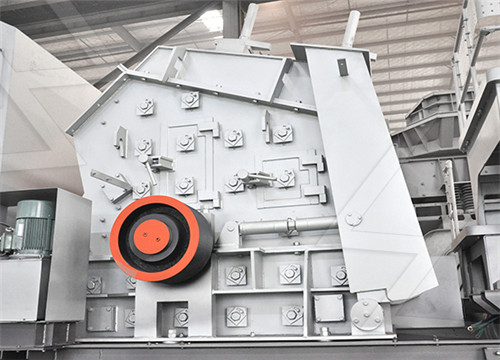

– Jaw crushers Gyratory crushers . Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 20-30° with the fixed jaw

Review Paper on Swing Jaw Plate in Jaw Crusher Machine

on the mechanism used crushers are of three types namely Cone crusher, Jaw crusher and Impact crusher. The first stage of size reduction of hard and large lumps of run-of-mine (ROM) ore is to crush and reduce their size. Large scale crushing operations are generally performed by mechanically operated equipment like jaw crushers, gyratory

HSE Quarries Safe operation and use of mobile jaw crushers

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not comprehensive.

Jaw Crushers JW Series

MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155-480 (140-435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder The only warranty applicable to our equipment is the standard written warranty applicable to the particular product and sale, and makes no other warranty

® C Series™ jaw crushers Proven reliability and

aspect when considering the performance of a jaw crusher. Our industry-leading stroke is amplified from top to bottom, being at its longest in the lower parts of the cavity. This increases the open area between the jaw dies allowing the material to have more space to get out, while also enabling inter-particle crushing. This design principle

Metso ® C Series™ jaw parts

maximize on the life of the wear parts, the crusher cavity should be full. • The feed must be distributed evenly across the crushing chamber. 3. Apply proper scalping • Fines (material smaller then CSS) should be removed from the feed material. This is done by the grizzly bar section of the feeder. Fines in the jaw crusher increase

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017年6月30日A pitman of a jaw crusher has an upper part, which includes an upper supporting point for supporting the pitman in the body of the jaw crusher, and a lower part having a lower supporting point for

Design and Construction of Rock Crushing Machine from

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic

(PDF) Material Selection for Crusher Jaw in a Jaw

2015年11月9日18 Adelana Rasaki Adetunji et al.: Material Selection for Crusher Jaw in a Jaw Crusher Equipment adopted for various designs (Chan and Zhou, 199 4 and Dieter, 1991) .

EQUIPMENT AND MAINTENANCE

result of joint efforts on the part of operators and manufac turers. During normal crushing, two factors can lead to the destruction of expensive crusher parts; the introduction of an uncrushable item, e.g. tramp iron or mine timbers, and a phenomenon called packing. This is caused when a large amount of fines enters the crushing chamber and

Review Paper on Swing Jaw Plate in Jaw Crusher Machine

on the mechanism used crushers are of three types namely Cone crusher, Jaw crusher and Impact crusher. The first stage of size reduction of hard and large lumps of run-of-mine (ROM) ore is to crush and reduce their size. Large scale crushing operations are generally performed by mechanically operated equipment like jaw crushers, gyratory

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

– Jaw crushers Gyratory crushers . Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 20-30° with the fixed jaw

HSE Quarries Safe operation and use of mobile jaw crushers

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not comprehensive.

Jaw crushers, Stationary Jaw crusher series — SRP

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are delivered with everything you need for plug-and-play installation and safety features to keep operators out of danger. Backed up with a complete Reliability and Protection package, they get

MPS CrushingScreening Equipment

At MPS we produce a range of crushing and screening equipment to suit all your crushing and classifying needs. Whether you're on the move, need a temporary solution, or have a large static operation, our Cedarapids, Simplicity and Canica brands will have the equipment for your needs. Cedarapids CrushingScreening Equipment.

Crusher an overview ScienceDirect Topics

The common primary crushers are of jaw and gyratory types. The jaw crusher reduces the size of large rocks by dropping them into a “V”-shaped mouth at the top of the crusher chamber. This is created between one fixed rigid jaw and a pivoting swing jaw set at acute angles to each other.