Wet Mining Separation Equipment

Derrick Corporation Solids Control and Fine Wet / Dry

With 8 decks operating in parallel and innovative Front-to-Back (FTB) tensioning system, the SuperStack has a demonstrated capacity up to 3 times that of the best fine screens currently available. Highest Capacity,

Classifiers for dry and wet separation Metso Outotec

World class wet classification technology for a wide variety of ores such as copper, gold, iron, lead, zinc and industrial minerals. Air classifiers Effectively classify materials such

Mining separation and sorting equipment for

MINING Mining separation magnetic separation and sensor sorting solutions for improved throughput and recovery rates in ore sorting and mineral processing From traditional and trusted magnetic separation

Derrick Multifeed, wet sizing, separation equipment,

Derrick’s Multifeed Wet Sizing Screen consists of three independent screening units which provide three times the effective width of a

Sand WashingWaste Recycling Wet Processing Solutions CDE

We have been co-creating with customers for 30 years to deliver imaginative wet processing systems with over 2,000 successful projects installed around the world. Wet processing

Choosing a Gravity Separation Process: Dry vs. Wet

2021年7月23日Wet Gravity Separation Processing for Efficient Particle Separation Easier separation and lower equipment wear are the fundamental reasons that wet separation is used rather than dry or air

Separation Equipment Mining Technology

Engineered Solutions and Equipment for Wet Mechanical Processing and Process Water Management. Bulk Material Handling and Separation Equipment for Mines. E.

Wet Separation Tables Cable Management

Based in Croatia, Metal Marketing is Europe’s largest manufacturer and exporter of wet separation technologies. They have established a reputation for extremely well built equipment and have technical support

Dry and Wet Screening in Mining: What are the Differences?

2018年2月14日First of all, wet separation technology requires additional equipment, including the spray nozzles that funnel the water. Extra plant capital is on the agenda

Derrick Corporation Solids Control and Fine Wet /

With 8 decks operating in parallel and innovative Front-to-Back (FTB) tensioning system, the SuperStack has a demonstrated capacity up to 3 times that of the best fine screens currently available. Highest Capacity,

Mining separation and sorting equipment for processes in the mining

Mining separation and sorting equipment for processes in the mining industry • STEINERT Sorting equipment specifically developed for the mining industry pre-concentration low grade stockpile treatment industrial minerals precious stones coal Toggle navigation News Company About us Philosophy History Subsidiaries Business unit

Magnetic separation Metso Outotec

Metso Outotec magnetic separators enable superior separation selectivity and improved recovery of fine and ultra-fine particles. Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process. (VPHGMS). The unit is a wet, high-intensity magnetic separator that uses a

Derrick Mining Technology

Our separation technology equipment offers a high solids removal performance. Customers use this equipment and innovative screen technology to consistently recycle and reuse drilling fluid while monitoring drilled solids and the environmental impact. Further removal of ultra-fine drilled solids is performed by Derrick®’s decanting centrifuges.

Derrick Multifeed, wet sizing, separation

Derrick’s Multifeed Wet Sizing Screen consists of three independent screening units which provide three times the effective width of a conventional screen, mounted in a single frame and driven by one

Sand WashingWaste Recycling Wet Processing Solutions CDE

We have been co-creating with customers for 30 years to deliver imaginative wet processing systems with over 2,000 successful projects installed around the world. Wet processing equipment is our sole focus. No other business can

Wet High Intensity Magnetic Separators Multotec

Separate ferromagnetic and paramagnetic particles and tramp metals with the world’s most efficient solutions. Wet High Intensity Magnetic Separators (WHIMS) from Multotec combine magnetism, matrix rotation and gravity to para-magnetic materials. Applications include heavy minerals, ilmenite, manganese and iron ore (haematite) beneficiation

Separation Equipment Mining Technology

Engineered Solutions and Equipment for Wet Mechanical Processing and Process Water Management. Bulk Material Handling and Separation Equipment for Mines. E. Mining news and in-depth feature articles on the latest mining company deals and projects covering trends in mineral exploration with up to date data on the most mined metal and

Wet Separation Tables Cable Management

Based in Croatia, Metal Marketing is Europe’s largest manufacturer and exporter of wet separation technologies. They have established a reputation for extremely well built equipment and have technical support

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Generally, wet magnetic separation is required. 2. Three-disc Magnetic Separator. It is an essential beneficiation equipment for separating weak magnetic minerals and rare metal ores. There are two types of three-disk belt magnetic separators. Mining Equipment Manufacturers, Our Main Products: Gold Trommel, Gold Wash Plant, Dense

Products McLanahan

McLanahan Corporation offers wet and dry processing products for mining industries, as well as bedding and manure management products for the dairy industry. Manure Separation and Dewatering; Mixing/Blending; Mobile Equipment; Sampling; Screening/Sizing; Scrubbing; TailingsWater Management; WashingClassifying;

Small Gasoline Gold Washing Machine JXSC Mineral

Magnetic Separation. Wet Drum Magnetic Separator; Three Disc Dry Magnetic Separator; Dry High Intensity Magnetic Separator; Flotation Equipment. JJF Flotation Cell; We provide ore process design, mining equipment production, and solutions. China Mining Equipment Manufacturer. Contact Tel: +86- E-Mail: [email protected] Main

Wet Sampling Sampling Equipment Multotec

Wet Sampling. Multotec is a leading provider of reputable wet sampling solutions and range of sampling equipment, including those for sample preparation, to the global mining and minerals market. Their accredited sampling design focuses on all precious and base metals, uranium, phosphate, titanium oxide, tungsten, industrial and various other

Choosing a Gravity Separation Process: Dry vs. Wet Processing

2021年7月23日Wet Gravity Separation Processing for Efficient Particle Separation Easier separation and lower equipment wear are the fundamental reasons that wet separation is used rather than dry or air separation processes—especially for very fine particle separation.

Derrick Corporation Solids Control and Fine Wet /

With 8 decks operating in parallel and innovative Front-to-Back (FTB) tensioning system, the SuperStack has a demonstrated capacity up to 3 times that of the best fine screens currently available. Highest Capacity,

Magnetic separation Metso Outotec

Metso Outotec magnetic separators enable superior separation selectivity and improved recovery of fine and ultra-fine particles. Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process. (VPHGMS). The unit is a wet, high-intensity magnetic separator that uses a

Derrick Multifeed, wet sizing, separation

Derrick’s Multifeed Wet Sizing Screen consists of three independent screening units which provide three times the effective width of a conventional screen, mounted in a single frame and driven by one

Wet High Intensity Magnetic Separators Multotec

Wet High Intensity Magnetic Separators (WHIMS) Separate ferromagnetic and paramagnetic particles and tramp metals with the world’s most efficient solutions. Wet High Intensity Magnetic Separators (WHIMS) from Multotec combine magnetism, matrix rotation and gravity to para-magnetic materials.

Products McLanahan

McLanahan Corporation offers wet and dry processing products for mining industries, as well as bedding and manure management products for the dairy industry. Manure Separation and Dewatering; Mixing/Blending; Mobile Equipment; Sampling; Screening/Sizing; Scrubbing; TailingsWater Management; WashingClassifying;

Separation Equipment Mining Technology

Engineered Solutions and Equipment for Wet Mechanical Processing and Process Water Management. Bulk Material Handling and Separation Equipment for Mines. E. Mining news and in-depth feature articles on the latest mining company deals and projects covering trends in mineral exploration with up to date data on the most mined metal and

Choosing a Gravity Separation Process: Dry vs. Wet

2021年7月23日Wet Gravity Separation Processing for Efficient Particle Separation Easier separation and lower equipment wear are the fundamental reasons that wet separation is used rather than dry or air

Wet Separation Tables Cable Management

Based in Croatia, Metal Marketing is Europe’s largest manufacturer and exporter of wet separation technologies. They have established a reputation for extremely well built equipment and have technical support

Wet Sampling Sampling Equipment Multotec

Wet Sampling. Multotec is a leading provider of reputable wet sampling solutions and range of sampling equipment, including those for sample preparation, to the global mining and minerals market. Their accredited

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Generally, wet magnetic separation is required. 2. Three-disc Magnetic Separator. It is an essential beneficiation equipment for separating weak magnetic minerals and rare metal ores. There are two types of three-disk belt magnetic separators. Mining Equipment Manufacturers, Our Main Products: Gold Trommel, Gold Wash Plant, Dense

Small Gasoline Gold Washing Machine JXSC Mineral

Magnetic Separation. Wet Drum Magnetic Separator; Three Disc Dry Magnetic Separator; Dry High Intensity Magnetic Separator; Flotation Equipment. JJF Flotation Cell; We provide ore process design, mining equipment production, and solutions. China Mining Equipment Manufacturer. Contact Tel: +86- E-Mail: [email protected] Main

Low Intensity Magnetic Separators (LIMS) Metso Outotec

The wet versions are designed for material of a few micrometer size to less than around 6 8 millimeters suspended in water. For both separator types two magnetic systems are available for highest possible efficiency of each application. Benefits High capacity LIMS have proven to have outstandingly high capacity thus fewer machines are required.

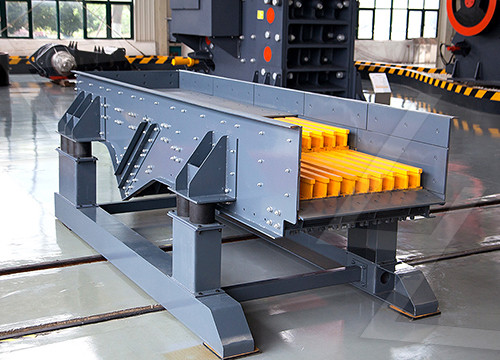

Screening/Sizing McLanahan

Screening equipment is commonly used to size and separate material throughout the production process. Screens used ahead of a primary crusher can remove fine material, like abrasive stone or sand, which can cause wear and tear on the crusher’s liners.

Geosciences Free Full-Text Membrane Separation of

2018年2月24日The separation of ammonium bisulfate (ABS) from ammonium sulfate (AS) in aqueous solutions by monovalent ion selective membranes was studied. Optimised usage of these chemicals is both an important and challenging step towards a more efficient CO2 mineralisation process route developed at Åbo Akademi University (ÅA). The