Standard 1 Fine Cone Crusher

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of

CH440 Cone Crusher With A Robust Crusher Design

CH440 Cone crusher. CH440 cone crusher is an advanced design, with a small footprint and high capacity in relation to size, and a

All crusher types for your reduction needs Metso Outotec

For cone crushers there are few rules to be followed of optimum cubical shape. These ‘Ten Golden Rules’ are: Full crushing chamber. This means that cone head must be covered by rock. Stable and continuous feed.

Cone Crushers For Sale MyLittleSalesman

2023年2月14日Telsmith 48S Standard Cone Crusher Recently Updated $65,000 USD Telsmith 48 S standard cone crusher in good running condition. Comes with complete

Cone Crushers Moore Watson Ltd

Cone crusher Cone crushers CC100 CC200 CC400 CC300 MHP400 MHP500. top of page. MOORE WATSON LTD. CC-S crushers. Three standard crushing chambers

What is the difference between a standard and shorthead

2023年2月7日Cone crushers come in two main types: standard and shorthead. The standard cone crusher has a large head angle, coarser discharge, and higher capacity,

Difference between standard medium and short head

1. The shape of crushing chamber is different The parallel belt of the short head cone crusher is longer, the medium-sized one is the second, and the standard type is the

Short Head Vs Standard Head Cone Crusher Mills

4FT short head cone crusher Shanghai liming Machinery. CS series cone crushers (2ft, 3ft, 4 1/4ft, 5 1/2 feet standard and short head cone crusher) with capacity 50-400, 500

Cone Crusher an overview ScienceDirect Topics

The Standard cone crushers are for normal use. The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required. These

CH440 Cone Crusher With A Robust Crusher

Several standard crushing chambers are available for each model. The crushers can easily be matched to changes in production by selecting the right chamber and eccentric throw. The chambers available are: EF =

Mobile Cone Crushers, Mobile Cone Crusher Series — SRP

Offering large reduction ratios with minimal fines production, mobile cone crushers are the ideal solution for secondary and tertiary crushing. Our market leading "S" type cones can accept a feed size up to 90% larger than current standard cones; they can even be run as primary crushers on gravel applications.

Cone Crushers MEKA CrushingScreening Plants

The cone crusher’s optimised speed and improved crushing chamber design provides high productivity with less wear on parts, meaning a great savings in labour. The adjustable crushing chamber can provide the

Cone Crushers For Sale MyLittleSalesman

2023年2月14日Telsmith 48S Standard Cone Crusher Recently Updated $65,000 USD Telsmith 48 S standard cone crusher in good running condition. Comes with complete lube tank and correct electric motor..can be seen anytime, $60,000. Financing is available. (844) 686-___ SHOW NUMBER Email Seller More Info 1 0 1000 Maxtrak Cone

Cone Crushers Moore Watson Ltd

The MP Cone Crusher is advanced in design, more compact with a higher crushing ability and efficiency to provide better size reduction. Operators can choose the auto control mode, various chambers and other features by adjusting the closed side settings (CSS). All models are easy to operate and maintain, with high production and efficiency.

A Detailed Overview of Cone Crushers and What

2020年6月3日The unsung hero of the entire machine, the motor is what drives the mantle and allows crushing to take place. These motors are incredibly powerful and capable of generating a massive amount of

What is the difference between a standard and shorthead cone crusher?

2023年2月7日Cone crushers come in two main types: standard and shorthead. The standard cone crusher has a large head angle, coarser discharge, and higher capacity, while the shorthead cone...

Difference between standard medium and short head cone crushers

1. The shape of crushing chamber is different. The parallel belt of the short head cone crusher is longer, the medium-sized one is the second, and the standard type is the shortest. 2. The particle size of crushed products is different. The short head cone crusher with long parallel belt can crush fine materials.

Cone Crusher Manufacturer Cloud Computing at ETW

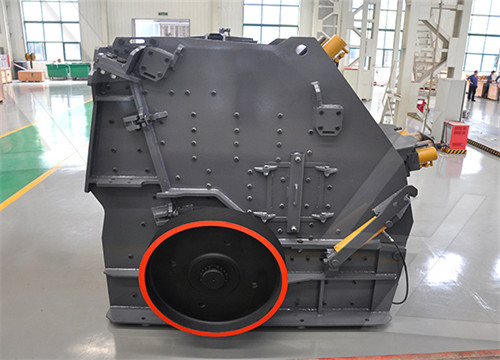

For crushing materials of medium hardness, the PYB type (standard type) machine is used. Fine materials are effectively crushed using the short head type. 1. The cone crusher is made up of a frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs, and hydraulic pressure station for adjusting the

MCC Series Cone Crusher Minyu Machinery Corp.

2022年2月24日The MCC Series Cone Crusher by Minyu is used for standard or coarse crushing and can be stationary or portable. Skip to content. Menu. Crushing. Cone Crushers; Jaw Crushers; Impact

Symons Cone Crusher 911Metallurgist

One of the first cone crushers had a direct drive vertical motor mounted above the spider with the drive shaft passing through the hollow bored main shaft. With relatively high speeds of 480 to 580 rpm and small eccentric

The pros and cons of cone crusher applications Quarry

2021年4月16日A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per

Maximize your cone crusher productivity : PitQuarry

2017年4月28日Every cone crusher has three design limitations. These are the volume limit, the horsepower limit and the crushing force limit. Regarding the volume limit, each crushing cavity has a volumetric limit that determines maximum throughput, and a choke-fed crusher is operating at its volumetric limit.

® HP Series™ cone crushers Metso Outotec

® HP Series™ cone crushers are the most popular modern cone crushers in the world with over 10,000 machines sold globally. Menu and select the product size distribution according to your preference of coarse or fine aggregate production. Technical specifications. ® HP Series™ cone crushers technical specifications

CH440 Cone Crusher With A Robust Crusher

Several standard crushing chambers are available for each model. The crushers can easily be matched to changes in production by selecting the right chamber and eccentric throw. The chambers available are: EF =

Mobile Cone Crushers, Mobile Cone Crusher Series — SRP

Offering large reduction ratios with minimal fines production, mobile cone crushers are the ideal solution for secondary and tertiary crushing. Our market leading "S" type cones can accept a feed size up to 90% larger than current standard cones; they can even be run as primary crushers on gravel applications.

Cone crushers for demanding crushing needs

Cone crushers are suitable for all demanding crushing needs. Cone crushers are very suitable for size reduction and shaping in the downstream of a crushing circuit. They reduce the material in a crushing cavity by

MCC Series Cone Crusher Minyu Machinery Corp.

2022年2月24日MCC Cone Crusher There are generally four types of Standard Cone Crushers: the MCC Standard or Coarse type, the MCF Fine or Medium type, the MCS Short Head typeMCSS Super Fine

A Detailed Overview of Cone Crushers and What

2020年6月3日A cone crusher has two sides: an open side and a closed side. As the material crushes, the particles that are small enough to fit through the open side fall through the space between the mantle and the

The pros and cons of cone crusher applications Quarry

2021年4月16日A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per

Difference between standard medium and short head cone crushers

1. The shape of crushing chamber is different. The parallel belt of the short head cone crusher is longer, the medium-sized one is the second, and the standard type is the shortest. 2. The particle size of crushed products is different. The short head cone crusher with long parallel belt can crush fine materials.

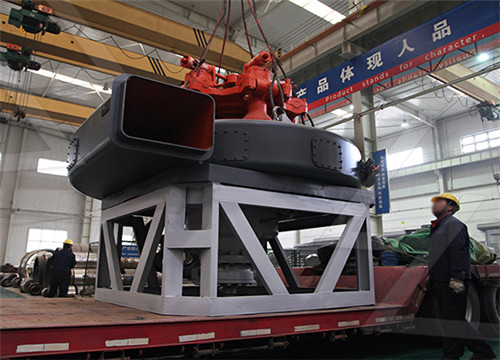

standard cone crusher PYB600

P ictures standard cone crusher PYB600. Introduction for standard cone crusher PYB600. PYB 600, 900, 1200 cone crushers are widely used for medium and fine crushing in mining, chemical industry, building materials, metallurgy and other fields. The cone crusher can crush iron ore, copper ore, limestone, quartz, granite, rock and other

Cone Crusher Manufacturer Cloud Computing at ETW

For crushing materials of medium hardness, the PYB type (standard type) machine is used. Fine materials are effectively crushed using the short head type. 1. The cone crusher is made up of a frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs, and hydraulic pressure station for adjusting the

Crushing Products Size and Shape -What to Expect

2016年2月26日Following the curve down to the 1.5″ line, we find that 43% of the primary crusher output may be expected to pass this screen opening; 57% will be retained, which means that we must provide secondary

® HP Series™ cone crushers Metso Outotec

® HP Series™ cone crushers are the most popular modern cone crushers in the world with over 10,000 machines sold globally. Menu and select the product size distribution according to your preference of coarse or fine aggregate production. Technical specifications. ® HP Series™ cone crushers technical specifications

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Cone crusher and short head cone: feed diameter < 25 cm; reduction ratio 5:1 to 10:1 usually 7:1; capacity 5 to 300 kg/s: Mohs hardness < 8. Usually secondary or tertiary crusher. Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to 10:1; capacity 0.3 to 50 kg/s.

Used Cone Crushers for Sale Surplus Record

51" Symons, Standard Cone Crushe, Hydraulic Adjust, 400 TPH Category: Cone Crushers Seller: D'Angelo International Location: Bellingham, WA Mfr: Symons Crusher disassembled, inspected, parts being repaired and replaced as needed, Hydraulic adjust with console, Lubrication system with tank, pump, and temperature and pressure

Quarry Crawler Type Portable Stone Jaw Crusher Machine

Features of Our Crawler Mobile Crusher. 1. Strong power of diesel engines, Low fuel consumption and noise, powerful horsepower, energy saving and high yield. 2. Convenient and fast, Outlet size can be controlled by hydraulic, with advantages of convenient and fast. 3. Intelligent operation With wireless remote control, self-tracked walking.. 4. All-steel