Gyratory Roll Mining Mill Operations

Mineral Processing Design and Operations ScienceDirect

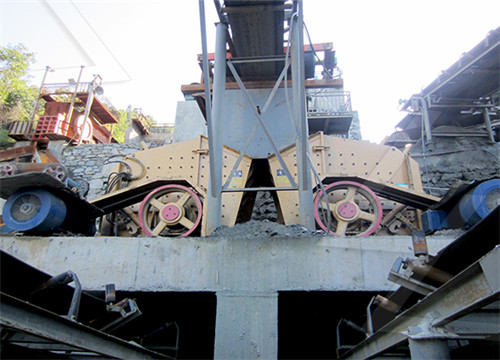

This chapter deals with the designs and operation of different types of roll crushers. Two main types are indicated. The first type where the rolls are rotated in opposite direction

AMIT 135: Lesson 5 Crushing Mining Mill Operator

Gyratory Crushers Jaw Crushers Impact Crushers Typical rules for primary crusher selection: Rule 1: Always use a jaw crusher if you can due to

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in

Fuller®

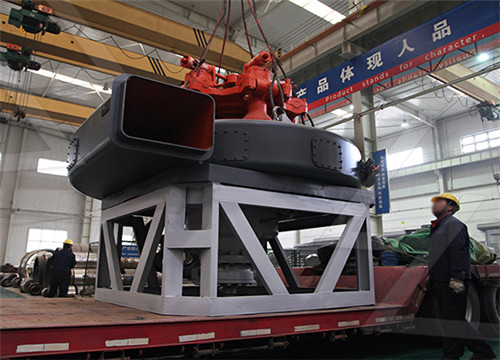

The first Gyratory Crushers were designed and built to meet the need for large capacity, great strength and easy adjustment to maintain the size of product. The Gyratory Crusher gave Fuller-Traylor a reputation

HPGR High Pressure Grinding Rolls Mineral Processing

2016年7月13日The largest HPGR Polycom in operation (Figure 5) using a maximum roll diameter of 2.2 meters is processing diamond-bearing rocks in Australia at a maximum feed rate of 600 to 800 mt/h with a top feed

Rock Crushing Process in Mining Mineral Processing

2015年7月18日Gyratory crushers have the largest unrestricted opening when compared to other crushers. Standard crusher feed sizes range from 1067 mm (42”) to 1829 mm (72”). The 1067 mm gyratory crusher has

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for

Grinding technology and mill operations

Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding. Improving

blake type roll mining mill and the gyratory mining mill

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

UNITED STATES Climax Molybdenum A Freeport-McMoRan

The available underground mining equipment fleet consists of fourteen 9metric ton load-haul-dump (LHD) units and seven 73-metric ton haul trucks, which deliver ore to a gyratory crusher feeding a series of three overland conveyors to the mill stockpiles. The Henderson mine and mill operations encompass approximately 11,900 acres,

Industrial Solutions Gyratory crushers ThyssenKrupp

these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products. thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design features of grinding equipment (SAG, BALL and ROD MILLS)

en/roll mining mill operation principles.md at main lbsid/en

Contribute to lbsid/en development by creating an account on GitHub.

Rock Crusher History Mineral ProcessingMetallurgy

2015年4月16日Many small process plants consisted of one crusher, either jaw or gyratory rock crushers, one elevator and one screen. Recrushing, if done, was taken care of by the same machine handling the primary break. The single crusher, when of the gyratory type, might be any size from the No. 2 (6″ opening) to the No. 6 with 12-in. opening.

USA Vibro-gyratory mills Google Patents

USA 1974-02-26 Motion control for a material separator. USA 1971-10-05 Tumbling mill. USA 1973-11-13 Vibratory finishing apparatus with a helical and tubular container. USA 1970-06-02 Vertical dam. USA 1974-06-04 Vibro-gyratory mills. USA 1976-09-21 Finishing apparatus.

Grinding technology and mill operations

The operators and process engineers must be able to evaluate all the process variables in order to optimise the mill system production. The grinding technology and mill operations course provides the necessary knowledge to maximise the production rate and promote operational stability while ensuring the grinding systems operate efficiently.

blake type roll mining mill and the gyratory mining mill

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

What is the major step in the process of open-pit and underground mining?

2023年3月10日Published Mar 10, 2023. + Follow. Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of

Uses of Different Types of Crusher linkedin

2023年3月10日Gyratory Crushers: Gyratory crushers are used to crush hard and abrasive materials, such as iron ore, copper ore, and limestone. They are often used in the mining industry.

Crusher an overview ScienceDirect Topics

When the run of mine product is conveyed directly from the mine to the crusher, the feed to the primary crusher passes under a magnet to remove tramp steel collected during the mining operation. A grizzly screen is placed between the magnet and the receiving hopper of the crusher to scalp (remove) boulders larger than the size of the gape.

Working Principle of Crushers Mineral ProcessingMetallurgy

2016年2月17日Gyratory crushers are the most common for new operations. Secondary crushers are lighter-duty and include cone crushers, roll crushers, and impact crushers. Generally, the feed to these machines will be less than 15 cm, and secondary crushing is usually done on dry feed.

Different types of crushing equipments Constro Facilitator

2020年5月6日Gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. The new primary gyratory crushers have new advancements that bring increased speeds, higher installed power and mechanical improvements. All of these combine to bring additional throughput for your primary

UNITED STATES Climax Molybdenum A Freeport-McMoRan

The available underground mining equipment fleet consists of fourteen 9metric ton load-haul-dump (LHD) units and seven 73-metric ton haul trucks, which deliver ore to a gyratory crusher feeding a series of three overland conveyors to the mill stockpiles. The Henderson mine and mill operations encompass approximately 11,900 acres,

Industrial Solutions Gyratory crushers ThyssenKrupp

these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products. thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design features of grinding equipment (SAG, BALL and ROD MILLS)

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner. Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface.

en/roll mining mill operation principles.md at main lbsid/en

Contribute to lbsid/en development by creating an account on GitHub.

USA Vibro-gyratory mills Google Patents

USA 1974-02-26 Motion control for a material separator. USA 1971-10-05 Tumbling mill. USA 1973-11-13 Vibratory finishing apparatus with a helical and tubular container. USA 1970-06-02 Vertical dam. USA 1974-06-04 Vibro-gyratory mills. USA 1976-09-21 Finishing apparatus.

Grinding technology and mill operations

The operators and process engineers must be able to evaluate all the process variables in order to optimise the mill system production. The grinding technology and mill operations course provides the necessary knowledge to maximise the production rate and promote operational stability while ensuring the grinding systems operate efficiently.

sbm/sbm tgyratory ball mill operations.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

What is the major step in the process of open-pit and underground mining?

2023年3月10日Published Mar 10, 2023. + Follow. Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of

Uses of Different Types of Crusher linkedin

2023年3月10日Gyratory Crushers: Gyratory crushers are used to crush hard and abrasive materials, such as iron ore, copper ore, and limestone. They are often used in the mining industry.

Different types of crushing equipments Constro Facilitator

2020年5月6日Gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. The new primary gyratory crushers have new advancements that bring increased speeds, higher installed power and mechanical improvements. All of these combine to bring additional throughput for your primary

gyratory crusher operation MiningQuarry Plant

2013年3月15日Find the Right and the Top gyratory crusher operation for your coal handling plant! kefid, a mining machines manufacturer in china focus on your local solutions service gyratory crusher principle of operation beltconveyers.net

Cone Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher In Mineral Processing Design and Operations (Second Edition), 2016 5.2.2 Secondary and tertiary cone crushers Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers.