Sintered Copper Ore And Frame Flotation Cell

A Review of the Flotation of Copper Minerals

2017年7月4日The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 0.5%TCu (open pit

Optimizing the Rougher Flotation Process of Copper Ore

根据热度为您推荐•反馈

Statistical investigation of flotation parameters for copper

2021年3月1日Flotation experiments were performed in a 2,5 L Denver flotation cell to upgrade Cu and Co (bulk flotation) recoveries from flotation tailings.A specific mass of

The Challenges and Prospects of Recovering Fine Copper Sulfides

2022年5月6日Flotation is a common mineral processing method used to upgrade copper sulfide ores; in this method, copper sulfide mineral particles are concentrated in froth,

1 Froth Flotation Fundamental Principles

Problem: A copper ore initially contains 2.09% Cu. After carrying out a froth flotation separation, the products are as shown in Table 1. Using this data, calculate: Figure 5:

Optimizing the Rougher Flotation Process of Copper Ore

2019年2月22日To model the copper ore flotation process, an analysis was made on the factors that affect the results of the process. We choose the following seven factors as

How to maximize ore and grade recovery through flotation

2020年3月6日The key to avoid recovery losses is to ensure that you install the right flotation solution in your process. Attributes such as innovative tank design, efficient air and level control, proven drive systems with safe

Flotation of copper ore in a pneumatic flotation cell

1992年2月1日The adaptability of pneumatic flotation cells for the flotation of sulfide ore and the conditions for sulfide ore flotation in pneumatic cells were investigated. The

Copper Flotation Mineral ProcessingMetallurgy

2016年5月16日A Copper Flotation Flowsheet Because the copper in this type of ore usually assays only plus or minus 1% copper, the porphyry copper operations must be relatively large in order to be commercial.

Copper Sulfide Flotation Mineral ProcessingMetallurgy

2016年4月13日Copper Ore Grinding Circuit Feed control is essential to efficient grinding and helps reduce surges and fluctuations throughout the entire plant. The Ball Mill in closed circuit with a Spiral Classifier

A Review of the Flotation of Copper Minerals

2017年7月4日The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 0.5%TCu (open pit mines) and 1-2%TCu (underground mines) is of great commercial...

Statistical investigation of flotation parameters for copper

2021年3月1日A maximum recovery of copper was 88,58% while the grade was 2,88 with 32,29 copper oxide on the total massive copper under the flotation conditions: 1,15 pulp density, 10 g/t dosage collector, 10 g/t dosage frother, and 50 g/t dosage dispersant and the maximum grade 12,24 while the recovery was 47,02% under the flotation conditions:

Recovery of pyrite from copper tailings by flotation

2019年9月1日The rougher flotation tests were performed in a Denver D-12 flotation machine with a 2.5 L cell. In each rougher flotation test, 2.260 L of fresh tailing pulp with 37.4 ± 1.3% solid by weight, 4.7 ± 0.3% pyrite grade, and pH 9.6 ± 04 were added in the cell and agitated at an impeller rotation speed of 1400 rpm.

1 Froth Flotation Fundamental Principles

Problem: A copper ore initially contains 2.09% Cu. After carrying out a froth flotation separation, the products are as shown in Table 1. Using this data, calculate: Figure 5: Simplified schematic of a conventional flotation cell. The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down

(PDF) Flotation of an Oxidized Copper Sulfide Ore

2017年1月1日Copper sulfide minerals are mined at copper mines and concentrated by flotation process. In recent years, the mining of refractory copper ores, which is difficult to concentrate by...

pH/ORP measurement Copper flotation process ABB

A high pH is important in copper ore processing to maximize this mineral’s flotation properties. Most copper ore slurries tend to be acidic. Plants typically add lime to the slurry in the mill or floatation circuit, increasing its alkalinity. A typical copper operation contains many flotation cells, often with a pH sensor in each cell.

Sustainable Use of Copper Resources: Beneficiation of Low-Grade Copper Ores

2022年4月27日Extensive research has been carried out on the flotation of copper sulphide ore as compared to copper oxide and mixed type ores. Besides flotation, other beneficiation techniques (selective flocculation and gravity separation) are also discussed in the present review.

How to maximize ore and grade recovery through

2020年3月6日Combining its extensive flotation circuit analysis capabilities with patented DV™ (Deep Vane) mechanism, the RCS™ flotation cells have the potential to significantly cut operating costs and

Froth Flotation Circuit Design And Basic Testwork Requirements

Each ore is different, and requires laboratory testing to evaluate the grind size, slurry pH, slurry density, required reagents and retention time to maximise recovery of the desired minerals into a flotation concentrate. Testwork necessary to define the design parameters for a flotation circuit generally includes: Grindability studies to

Evaluation of sodium isobutyl xanthate as a collector in the froth

2014年10月25日The Palabora copper ore ground 45 % passing 75 µm was successfully froth-floated with SIBX collector at varying dosages. The results obtained showed that the highest recovery of copper into the concentrate was obtained at 80 g/t dosage.

Sintering microstructure and properties of copper powder SpringerLink

2021年9月17日The almost completely dense copper was prepared by ultrafine copper powder prepared with both methods of electrolysis and novel water-gas atomization through cold isostatic pressing (CIP) and sintering under atmospheric hydrogen. Fine copper powder possesses the higher sintering driving force, thereby promoting shrinkage and

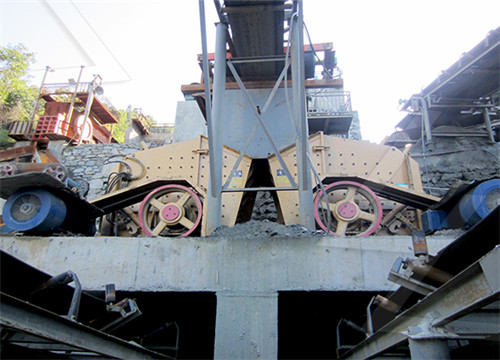

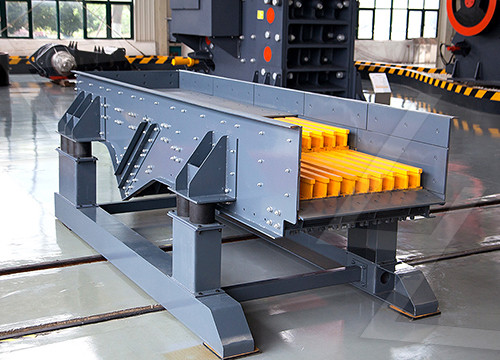

Flotation Cells Mineral ProcessingMetallurgy

2015年12月14日Flotation Cells Flotation Cells More ores are treated using froth flotation cells than by any other single machines or process. Non-metallics as well as metallics now being commercially recovered

Minerals Free Full-Text Design of Cell-Based Flotation Circuits

The design of cell-based flotation circuits is often completed in two distinct phases, namely circuit structure identification and equipment sizing selection. While recent literature studies have begun to address the implications of stochastic analysis, industrial practice in flotation circuit design still strongly favors the use of deterministic metallurgical modeling

Froth Flotation Process Mineral Processing

2021年1月20日Although the flotation of the commoner ores, notably those containing copper and lead-zinc minerals, has become standardized to some extent, there is nevertheless considerable variation in the

Statistical investigation of flotation parameters for copper

2021年3月1日Flotation experiments were performed in a 2,5 L Denver flotation cell to upgrade Cu and Co (bulk flotation) recoveries from flotation tailings.A specific mass of the tailing sample was poured into 500 mL of water to prepare slurry/feed with specific gravities in the range of 1,15 to 1,25.

A Review of the Flotation of Copper Minerals

2017年7月4日The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 0.5%TCu (open pit mines) and 1-2%TCu (underground mines) is of great commercial...

The Challenges and Prospects of Recovering Fine Copper Sulfides

2022年5月6日Flotation tailings mainly contain gangue minerals, while a significant amount of valuable copper sulfide particles is also contained. As shown in Table 1, it has been reported that around 10–20% of copper in the ore is lost in the tailings.

Sintering microstructure and properties of copper powder SpringerLink

2021年9月17日The almost completely dense copper was prepared by ultrafine copper powder prepared with both methods of electrolysis and novel water-gas atomization through cold isostatic pressing (CIP) and sintering under atmospheric hydrogen. Fine copper powder possesses the higher sintering driving force, thereby promoting shrinkage and

Sustainable Use of Copper Resources: Beneficiation of Low-Grade Copper Ores

2022年4月27日Extensive research has been carried out on the flotation of copper sulphide ore as compared to copper oxide and mixed type ores. Besides flotation, other beneficiation techniques (selective flocculation and gravity separation) are also discussed in the present review.

pH/ORP measurement Copper flotation process ABB

A high pH is important in copper ore processing to maximize this mineral’s flotation properties. Most copper ore slurries tend to be acidic. Plants typically add lime to the slurry in the mill or floatation circuit, increasing its alkalinity. A typical copper operation contains many flotation cells, often with a pH sensor in each cell.

Copper Ore an overview ScienceDirect Topics

This method is the most commonly used in beneficiation if oxide copper-bearing ore. The reagent schemes used to treat oxide copper ores, mixed copper sulphide oxide ores and oxide copper cobalt ores varies from one ore type to the next, mainly by type of collector and sulphidizer used.

An Experimental Investigation on the Copper Recovery from Flotation

2018年4月2日In this study, the possibility of copper recovery from flotation tailing of Mazraeh copper mine was investigated. Magnetic separation method was used for concentration of non-magnetic minerals, especially copper bearing minerals, from iron minerals. As a result, copper grade increased up to 0.18% and its recovery reached

(PDF) Flotation Equipment and Processes ResearchGate

2017年7月19日Flotation Equipment and Processes July 2017 Conference: New Directions in Mineral Processing At: Golden, Colorado Affiliation: Colorado School of Mines Special Programs and Continuing Education...

How to Process Copper Ore: Beneficiation Methods and Equipment

2023年2月15日Flotation is the most widely used method in copper mine production. The copper ore pulp is stirred and aerated, and the ore particles adhere to the foams under the action of various flotation agents. The foams rise to form a mineralized foam layer, which is scraped or overflowed by the scraper.

Froth Flotation Circuit Design And Basic Testwork Requirements

In the flotation process, ore is ground to a size sufficient to adequately liberate desired minerals from waste rock (gangue); it is conditioned as a slurry using specific chemicals, generically referred to as ‘collectors’, that adsorb to the surfaces of the desired minerals.

Froth Flotation Process Mineral ProcessingMetallurgy

2021年1月20日Although the flotation of the commoner ores, notably those containing copper and lead-zinc minerals, has become standardized to some extent, there is nevertheless considerable variation in the amount and nature of

copper ore impact ore flotation cells new github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Zinc Recovery From Lead–Zinc–Copper Complex Ores by Using Column Flotation

2012年5月15日Pb–Zn–Cu complex ore from Balıkesir–İvrindi district have been concentrated by GESOM A.Ş. using a selective mechanical flotation technique. Ore feeds containing 3.23% Pb, 0.52% Cu, and 2.71% Zn were concentrated by six stages of cleaning and four stages of scavenging. The final zinc concentrate which contains 2.13% Pb,