German Technical How To Operate Mobile Crushing Plant

Mobile crushers Metso Outotec

Mobile crushers are track-mounted rock crushing machines that are easily movable on and between production sites. They are widely used in aggregates production, recycling

Mobile jaw crushers for pre-crushing mpl Wirtgen Group

mpl products. Mobile jaw crushers. The crushing plants of the MOBICAT series are used for the precrushing of almost all natural rock and in recycling. However, the output

进一步探索

mpl MC 110 Z SpecificationsTechnical Data (200mpl Crusher Mc110 Evo Instruction Manual根据热度为您推荐•反馈

Small Crushing Plant Operating Guide Mineral

2016年1月26日A nuclear level switch is mounted at the coarse ore bin discharge chute to alarm at the crusher control panel and shutdown the apron feeder should the

Lokotrack® LT106™ mobile jaw crusher Metso Outotec

Robust and reliable mobile crusher. Lokotrack® LT106™ is equipped with ® C106™ jaw crushing unit,especially designed for crushing hard rock types such as

HSE Quarries Safe operation and use of mobile jaw

Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste. This guidance is for all those with responsibilities for

Fabo Company Mobile Crusher Plants Mobile Crusher

This operation is being done by heavy work machines that called crushing and screening plants. By those plants you can get any sizes are required of material. Those machines

Mobile Crushing Plant And Screening Plant Large

A mobile crusher plant (Mobile crushing and screening plant) is equipment that could crush large block material by multi-stage crushing and screening on the basis of specific

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing.. The Experts:

Track Mobile Crusher Plant, Mobile Crushing Plant GEP ECOTECH

GEP Ecotech's mobile crushing plants are available on both tire and crawler chassis, with the tire chassis crushing plants using tractor-trailers for easy and cost-effective for long

MR 130i EVO2 Mobile impact crushers mpl Wirtgen

The mobile impact crusher MOBIREX MR 130i EVO2 can be deployed universally as an all-rounder and produces first-class final grain quality. With a crusher inlet width of 1300 mm, it achieves a production rate that until now was only associated with considerably larger crushing plants. This is made possible by outstanding cost effectiveness and

Mobile crushers Metso Outotec

Mobile crushers are track-mounted rock crushing machines that are easily movable on and between production sites. They are widely used in aggregates production, recycling applications, and in mining operations. Mobile crushers can replace stationary crushing systems, which reduces the need for hauling and thus cuts operational costs.

Lokotrack® LT Series mobile crushers Metso Outotec

Lokotrack® LT Series mobile crushers are often referred to as ‘mobile crushing plants’. They are track-mounted crushing machines which, thanks to their mobility, can maximise productivity and reduce operating costs while increasing safety and reducing environmental impact. The basic components of mobile crushers are almost the same as

Mobile jaw crushers for pre-crushing mpl Wirtgen Group

mpl products. Mobile jaw crushers. The crushing plants of the MOBICAT series are used for the precrushing of almost all natural rock and in recycling. However, the output of the MOBICAT crushing plants is determined not only by the jaw crusher alone in fact, the optimal interaction of all components plays a decisive role.

HSE Quarries Safe operation and use of mobile jaw crushers

Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste. This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile

Small Crushing Plant Operating Guide Mineral Processing

2016年1月26日Next. This EXAMPLE Small Crushing Plant is designed to crush 500 tonnes per day, operating 12 hours per day with an availability of 70%. The Plant will crush run-of-mine material (-16″) to 100%, passing 5/8″ at a rate of 60 tonnes per hour. Start-stop stations are provided for all equipment in this Plant at the crusher control panel, to

Crusher Works: Your Truly Mobile Screening and Crushing Solutions

Crusher Works: Your Truly Mobile Screening and Crushing Solutions

Mobile Crushing Plant And Screening Plant Large Capacity

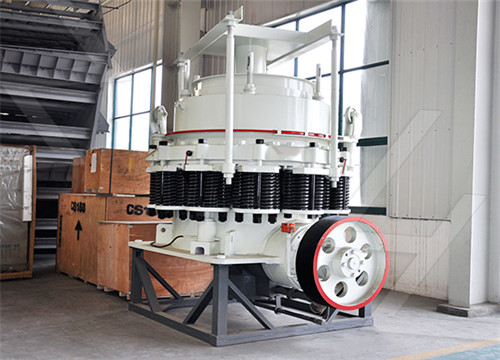

Mobile Cone Crusher Plants. Maxium Feed particle size: 160-215mm Production capacity: 50-420 t/h Application field: Mining, coal, waste, and the recycling of construction waste, urban infrastructure, roads or construction sites, and other site operations. For the material: Pebble, rock (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, sand, and

Crushing Plant FlowsheetDesign-Layout Mineral Processing

2016年3月10日Crushing Plant FlowsheetDesign-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone

Track Mobile Crusher Plant, Mobile Crushing Plant GEP

GEP Ecotech's mobile crushing plants are available on both tire and crawler chassis, with the tire chassis crushing plants using tractor-trailers for easy and cost-effective for long-distance transfers. Crawler chassis crushing plants are diesel or electrically powered with high passability. Allowing freedom of movement around the job site.

CrushingScreening Parker Plant

Parker offers simple solutions to mobile crushingscreening challenges. The CrushRangerHunter outfits are easily transportedcan be operational within hours of being on-site. The Hunter is a simple self-contained jaw-crushing unit that incorporates a rotary screenfeed platform. The CrushRanger models available are two stage, closed

Mobile crusher, Mobile crushing and screening plant All

mobile crawler compact. Contact. Capacity: 0 t/h 200 t/h. Motor power: 129 kW. Weight: 28,200, 28,000 kg. The is a highly compact, high performing tracked mobile jaw crushing plant featuring the “M” series single toggle jaw crusher. The new builds on the previously

Rationale for mobile crushing plants design methodology

2020年11月11日Methodology. The work of designers and constructors in choosing the type of PDPU layout scheme and elements of its design, as well as in improving the installation as a whole, is difficult due to

Risk Assessment Checklist

Crushing Plants: Site Date Time Instructions for personnel completing this Inspection; It is recommended this inspection be completed monthly. It is recommended a minimum of 2 persons conduct the inspection, one should be a health and safety representative of the work group (if present at the worksite) or a person qualified or experienced in

Lokotrack® LT Series mobile crushers Metso Outotec

Lokotrack® LT Series mobile crushers are often referred to as ‘mobile crushing plants’. They are track-mounted crushing machines which, thanks to their mobility, can maximise productivity and reduce operating

Mobile jaw crushers for pre-crushing mpl Wirtgen Group

The crushing plants of the MOBICAT series are used for the precrushing of almost all natural rock and in recycling. However, the output of the MOBICAT crushing plants is determined not only by the jaw crusher alone in fact, the optimal interaction of all components plays a decisive role.

Lokotrack® LT106™ mobile jaw crusher Metso

Metso Outotec IC™ process control system optimizes crushing results. It enables single-button start and stop and features in-built troubleshooting as well as various parameter selections. All Lokotrack® mobile crushers in

HSE Quarries Safe operation and use of mobile jaw crushers

Mobile crushers will normally be fed from loading shovels, backhoe excavators or from other processing machinery (eg sizer/separator, elevating conveyor, etc). In its simplest form it will be a...

Small Crushing Plant Operating Guide Mineral

2016年1月26日A nuclear level switch is mounted at the coarse ore bin discharge chute to alarm at the crusher control panel and shutdown the apron feeder should the level drop below a predetermined point. The

Track Mobile Crusher Plant, Mobile Crushing Plant GEP

GEP Ecotech's mobile crushing plants are available on both tire and crawler chassis, with the tire chassis crushing plants using tractor-trailers for easy and cost-effective for long-distance transfers. Crawler chassis crushing plants are diesel or electrically powered with high passability. Allowing freedom of movement around the job site.

CrushingScreening Parker Plant

Parker offers simple solutions to mobile crushingscreening challenges. The CrushRangerHunter outfits are easily transportedcan be operational within hours of being on-site. The Hunter is a simple self-contained jaw-crushing unit that incorporates a rotary screenfeed platform. The CrushRanger models available are two stage, closed

Crusher Works: Your Truly Mobile Screening and Crushing Solutions

Crusher Works: Your Truly Mobile Screening and Crushing Solutions

Crushing Plant Startup SequenceProcedure

2016年1月26日All the Crushing Plant equipment is interlocked, except for the sump pump, and therefore, the plant must be started from the fine ore bin back. The dust collector and scrubber bottoms pump are

Mobile crusher, Mobile crushing and screening plant

mobile crawler compact. Contact. Capacity: 0 t/h 200 t/h. Motor power: 129 kW. Weight: 28,200, 28,000 kg. The is a highly compact, high performing tracked mobile jaw crushing plant featuring

Risk Assessment Checklist

Engineering install guards on machines, put in barriers around hazards Administrative controls use policies, training and signs to warn workers Personal protective equipment (PPE)– use gloves, glasses, hearing protection etc. Personal protective equipmentis always thelast option used in the hierarchy of control as a means of protection!

Rationale for mobile crushing plants design methodology

2020年11月11日Methodology. The work of designers and constructors in choosing the type of PDPU layout scheme and elements of its design, as well as in improving the installation as a whole, is difficult due to

Mobile crushers and screens — SRP

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a crusher or screening aggregates after a crusher. Every product is backed by unrivaled aftermarket support to help keep your equipment running at optimum levels

mpl Launches a New Mobile Jaw Crushing Plant

2021年3月24日During the development of the mobile jaw crusher plant Mobicat MC 110(i) EVO2, mpl concentrated on the requirements of demolition and building companies, contractor crushers and quarry operators.With an hourly output of up to 400 t/h, the new mobile jaw crusher meets the requirements in the medium output range. It