Cement Roller Mill Crushing Efficiency

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日Grinding and separation efficiency of vertical roller mill were evaluated. In addition to these, performance figures of vertical

Premium solutions for the cement industry

根据热度为您推荐•反馈

Cement mill Wikipedia

OverviewBall MillsHistoryMaterials groundTemperature controlRoller millsHigh-pressure roll pressesCapacity of cement mills

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of high-chromium steel. The smaller grades are occasionally cylindrical ("pebs") rath

Modern Processing Techniques to minimize cost in

intensive unit operations involved in cement production are: • Crushing • Grinding systems • Pyroprocessing • Material handlingtransport 4.1 Crushing Most commonly used

Cement Roller Press, Roller Press In Cement Plant HPGR Crusher

As new-type and energy-efficient cement grinding machine, cement roller press has advantages of energy-saving, high efficiency, less steel consumption and less noise.

Grinding KHD Humboldt Wedag

Milling and crushing operations pose a number of headaches to cement plant operations. They consume large amounts of electrical energy. They are subject to severe abrasion.

Cement Plant Equipment Cement Crusher, Cement Mill, Cement

2019年11月21日Cement ball mill is core equipment for cement grinding. It has own advantages in operation, application, and structure, at present, cement ball mill has

Hydraulic Roller Press(HRP) SBCCO-CEMENT

The Hydraulic roller press (HRP) is used for cement grinding. Compared to the pre-grinding systems, including ball mills with high energy consumption and low efficiency, these cement mill roller presses consume less

roll crusher, roller crusher mill, dewomachinery

According to the particle size required by the user, roll crusher can be divided into smooth roller crusher and tooth roller crusher. Smooth roller crusher is suitable for fine crushing operations where the feed particle

Effects of circulating load and grinding feed on the grinding

2014年2月1日The crushing efficiency of the mill was also studied based on the sample analysis and material mass balance. The mathematics model about the mill crushing process was also established. Furthermore, the modeling work of the cement clinker broken by the mill was primarily obtained according to the laboratory simulation and mass

(PDF) Performance Evaluation of Vertical Roller Mill

2017年9月11日Grinding and separation efficiency of vertical roller mill were evaluated. In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared.

Technological Energy Efficiency Improvements in Cement Industries

The cement industry is highly energy-intensive, consuming approximately 7% of global industrial energy consumption each year. Improving production technology is a good strategy to reduce the energy needs of a cement plant. The market offers a wide variety of alternative solutions; besides, the literature already provides reviews of opportunities to

Long-lasting roller crusher and sizer solutions I

Robust roller crusher and sizer offering to maximise your crushing capabilities. Our roller crushers and sizers are built to last, with strong frames and self-lubrication systems to reduce your maintenance burdens. They offer reliable crushing of materials in the cement and mining industry, including highly-abrasive and sticky ones, and

Design, Fabrication and Testing of a Double Roll Crusher

theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%. cement production, metallurgy applications, chemical industries, electric Examples of grinders include attrition mills, roll- compression mill, fluid energy mill and ball mills [5]. The crushing of any particle takes place

Cement Plant Equipment Cement Crusher, Cement Mill, Cement

2019年11月21日Cement ball mill is core equipment for cement grinding. It has own advantages in operation, application, and structure, at present, cement ball mill has widest applications. High working efficiency, the cement ball mill produce uniform particles, increases the production capacity by 25%.

Cement plant modernization: energy efficiency and

Modernization of cement plants is one of the main ways to increase business competitiveness: project finance and EPC contracts

Grinding Mill Grinding Equipment Cement Mill

Cement vertical mill is a grinding equipment which emerges grinding, drying, powder separating and conveying into a single. It is widely used in the cement plant and electric power industry because of its high

Roller mill Tube mills had been used for grinding, but the

(4) This type of mill can crush materials which are too large to be fed into the tube (ball) mill. (5) Ground materials are dried by the flue gas from the kiln. Fig Schematic process flow of vertical roller mill for grinding of raw materials. Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results

What is Gypsum and How is it Used? mplcrusher

2023年3月10日The disadvantage is that the water content of gypsum is high, the crushing efficiency is low, and it is not easy to stir evenly when frying the gypsum. 3.The grinding and calcining of gypsum are carried out simultaneously. In this method, the block gypsum after coarse crushing is sent to the wind sweep type fast rotary grinding mill for

roll crusher, roller crusher mill, dewomachinery

According to the particle size required by the user, roll crusher can be divided into smooth roller crusher and tooth roller crusher. Smooth roller crusher is suitable for fine crushing operations where the feed particle

Four-roll Crusher Roll Crusher AGICO Roller Crusher Machine

The materials can be broken from 75mm to 0-10mm by this machine. Low noise, low vibration, low dust and low power consumption. This machine has the characteristic of high efficiency, safe operation, energy saving and environmental protection.

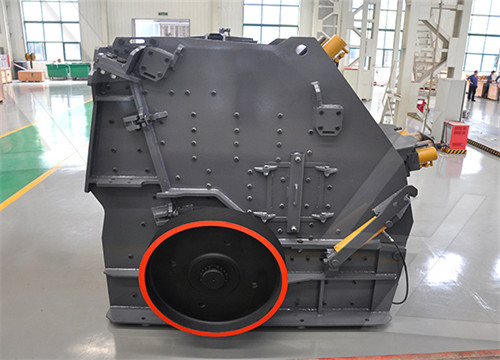

Cement hammer crusher rotor manufacturer of Wear Resistant

The rotor is the most important wear-resistant part for cement crusher and plays an important part in cement crushing process. Our company can customize various types of rotors in line with actual crusher types and clients' requirements to be applied for various hammer crushers and impact crushers. Cement Hammer Crusher Rotor

How to crush aggregates?

2023年3月7日Operate the crushing equipment according to the manufacturer's instructions. This typically involves setting the appropriate crushing parameters, such as the speed and pressure of the equipment

Effects of circulating load and grinding feed on the grinding

2014年2月1日The crushing efficiency of the mill was also studied based on the sample analysis and material mass balance. The mathematics model about the mill crushing process was also established. Furthermore, the modeling work of the cement clinker broken by the mill was primarily obtained according to the laboratory simulation and mass

Record-setting vertical roller mill exceeds performance

2020年12月1日A record-breaking mill does not disappoint . The world’s largest vertical roller mill at a cement plant as certified by Guinness World Records has completed performance guarantee testing, after operating successfully at Shah Cement Industries Ltd in Bangladesh.. Since starting operation, the OK™ 81-6 mill has exceeded its

(PDF) Performance Evaluation of Vertical Roller Mill

2017年9月11日Grinding and separation efficiency of vertical roller mill were evaluated. In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared.

Technological Energy Efficiency Improvements in Cement Industries

The cement industry is highly energy-intensive, consuming approximately 7% of global industrial energy consumption each year. Improving production technology is a good strategy to reduce the energy needs of a cement plant. The market offers a wide variety of alternative solutions; besides, the literature already provides reviews of opportunities to

Long-lasting roller crusher and sizer solutions I

Robust roller crusher and sizer offering to maximise your crushing capabilities. Our roller crushers and sizers are built to last, with strong frames and self-lubrication systems to reduce your maintenance burdens. They offer reliable crushing of materials in the cement and mining industry, including highly-abrasive and sticky ones, and

Design, Fabrication and Testing of a Double Roll Crusher

theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%. cement production, metallurgy applications, chemical industries, electric Examples of grinders include attrition mills, roll- compression mill, fluid energy mill and ball mills [5]. The crushing of any particle takes place

Cement plant modernization: energy efficiency and

Modernization of cement plants is one of the main ways to increase business competitiveness: project finance and EPC contracts

Grinding Mill Grinding Equipment Cement Mill

Cement vertical mill is a grinding equipment which emerges grinding, drying, powder separating and conveying into a single. It is widely used in the cement plant and electric power industry because of its high

roll crusher, roller crusher mill, dewomachinery

Features of Roller Crusher 1. High Crushing Rate, high crushing efficiency, low over-crushing rate; 2. Wear Resistant Parts: the double roll crusher roller is equipped with a replacement wear resistant lining

Roller mill Tube mills had been used for grinding, but the

(4) This type of mill can crush materials which are too large to be fed into the tube (ball) mill. (5) Ground materials are dried by the flue gas from the kiln. Fig Schematic process flow of vertical roller mill for grinding of raw materials. Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results

What is Gypsum and How is it Used? mplcrusher

2023年3月10日The disadvantage is that the water content of gypsum is high, the crushing efficiency is low, and it is not easy to stir evenly when frying the gypsum. 3.The grinding and calcining of gypsum are carried out simultaneously. In this method, the block gypsum after coarse crushing is sent to the wind sweep type fast rotary grinding mill for

Separators KHD Humboldt Wedag

From lowering costs to reducing environmental footprint, separators need to achieve high efficiency while lowering energy consumption. At KHD, we have a long history of innovation in separator technology. That tradition is part of our DNA and the basis for our continued technical development. Serving a range of applications from raw materials to cement, as

Cement hammer crusher rotor manufacturer of Wear Resistant

The rotor is the most important wear-resistant part for cement crusher and plays an important part in cement crushing process. Our company can customize various types of rotors in line with actual crusher types and clients' requirements to be applied for various hammer crushers and impact crushers. Cement Hammer Crusher Rotor