Calcium Carbonate Crusher Coconut Crushing Jaw Crusher

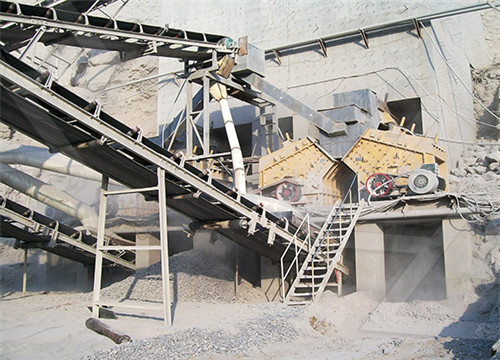

11.19.2 Crushed Stone Processing and Pulverized

crusher. Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable

进一步探索

Jaw Crushers Mt Baker Mining and Metals® C Series™ jaw crushers Metso Outotec根据热度为您推荐•反馈

Six factors that determine the capacity of calcium carbonate jaw

2020年12月18日Calcium carbonate jaw crusher is a commonly used crusher equipment, and it is a primary crushing equipment that is more commonly used in

PE-300 Small Stone Jaw Crusher Crusher for Calcium Carbonate

1.Product Description PE300x500 details PE300x500 H engtong Model PE300x500 jaw crusher feeding size is 255 mm, output size is 3 0-60 mm, capacity is 25-30 t/h. It's

Big capacity jaw crusher for sale Calcium Carbonate Grinding

Product Jaw Crusher Capacity:1-100 t/h Feeding size:125-480 mm Output Size:10-160 mm Jaw crusher is mainly used in the industries of metallurgy, mining, chemical, cement,

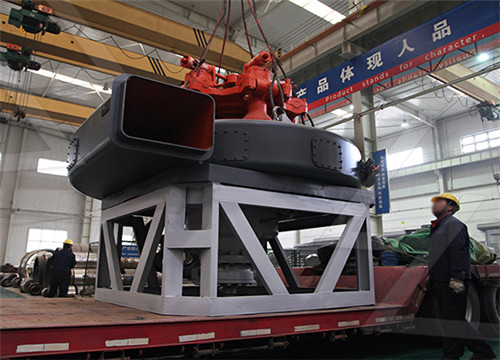

Crusher For Sale Various TypesModels: Jaw Crusher, Cone

And screen crusher is the machine to produce aggregates. As time goes by, it has developed many crusher machine types to suit different demands, such as jaw crusher,

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Jaw Crushers

jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries. These crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applications. Jaw crushers are typically used as primary crushers because they can

DBM Crushers, Grinding Mill, Mobile Crusher Machine For

2022年7月14日We provide four product series: crushing, sand making, grinding mill and beneficiation, mainly including jaw crusher, impact crusher, cone crusher, crushing production line, mobile crusher, sand making machine, and Raymond mill, ultra-fine grinding mill machine, ore power production line.

Jaw Crushers Parker Plant

Rocksledger Jaw Crushers. For primary stage medium to high capacity hard rock crushing or demolition applications. RockSledger jaw crushers feature massive, stress relieved, single plate walls with deep and substantial external side stiffeners and a high quality forged steel eccentric shaft. The shaft is fully machined and has a ground finish

jaw crusher for making granules of nurnt coconut shells

Jaw Crusher,small Jaw Crusher,used Jaw Crusher,Jaw Crusher, Jaw crusher includes large heavy Jaw crusher and small Jaw crusher. costs of calcium carbonate making machinery in japan Jaw crusher; costs of Jaw crusher; Go to Product Center. uses of pulveriser, impact crusher, coconut shell pulverizer

PE-300 Small Stone Jaw Crusher Crusher for Calcium Carbonate

1.Product Description PE300x500 details PE300x500 H engtong Model PE300x500 jaw crusher feeding size is 255 mm, output size is 3 0-60 mm, capacity is 25-30 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction

Jaw Crusher Calcium Carbonate Mining Equipment YouTube

2013年10月23日Jaw Crusher Calcium Carbonate Mining EquipmentMore Info:mineral-crusher/quarry-stone-crushing-machinehydraulic-gyratory-crusher/Contact Us:...

Crusher For Sale Various TypesModels: Jaw Crusher, Cone crusher..

And screen crusher is the machine to produce aggregates. As time goes by, it has developed many crusher machine types to suit different demands, such as jaw crusher, cone crusher, hammer crusher, impact crusher, hydraulic crusher, mobile crusher, VSI crusher and so on. For example, VSI crusher can produce sands.

Big capacity jaw crusher for sale Calcium Carbonate Grinding

Jaw Crusher. Capacity:1-100 t/h. Feeding size:125-480 mm. Output Size:10-160 mm. Jaw crusher is mainly used in the industries of metallurgy, mining, chemical, cement, construction, refractory materials and ceramics, suitable to crush hard and soft ores with compressive strength less than 320 MPa. This machine can break material s into. Inquiry

Hammermill Crushers McLanahan

The Standard and Non-Clog Hammermills are considered primary crushers, with some models capable of accepting a maximum feed size of 72" (1,830mm). The Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm).

All crusher types for your reduction needs Metso Outotec

Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce the material to a small enough size that it can be transported by conveyors to the next crushing stages. As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw.

What Are Jaw Crushers and How Do They Work? Oreflow

2019年3月28日The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

Crushing in Mineral Processing

2015年12月26日The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS CSS. OSS and CSS will define a crusher’s performance. The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS. The capacity is a function of

Estimate Jaw Crusher Capacity Mineral ProcessingMetallurgy

2016年2月17日Example, Metso C80 jaw crusher, 2″ CSS: Q = 0.8*(0.05+0.025)*0.025*cot(10°)*1.75*350*60 = 111 m³/h Where only a very small percentage of the feed approaches the size of the feed opening of the crusher, nonchoking crushing surfaces in a high capacity crusher may be advisable for the sake of

Jaw Crushers

Jaw Crushers jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries. These crushers are amongst the most advanced and reliable in the market and are highly productive in a

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

DBM Crushers, Grinding Mill, Mobile Crusher Machine For

2022年7月14日We provide four product series: crushing, sand making, grinding mill and beneficiation, mainly including jaw crusher, impact crusher, cone crusher, crushing production line, mobile crusher, sand making machine, and Raymond mill, ultra-fine grinding mill machine, ore power production line.

Jaw Crushers Parker Plant

Rocksledger Jaw Crushers. For primary stage medium to high capacity hard rock crushing or demolition applications. RockSledger jaw crushers feature massive, stress relieved, single plate walls with deep and substantial external side stiffeners and a high quality forged steel eccentric shaft. The shaft is fully machined and has a ground finish

Estimate Jaw Crusher Capacity Mineral ProcessingMetallurgy

2016年2月17日Example, Metso C80 jaw crusher, 2″ CSS: Q = 0.8*(0.05+0.025)*0.025*cot(10°)*1.75*350*60 = 111 m³/h Where only a very small percentage of the feed approaches the size of the feed opening of the crusher, nonchoking crushing surfaces in a high capacity crusher may be advisable for the sake of

jaw crusher for making granules of nurnt coconut shells

Jaw Crusher,small Jaw Crusher,used Jaw Crusher,Jaw Crusher, Jaw crusher includes large heavy Jaw crusher and small Jaw crusher. costs of calcium carbonate making machinery in japan Jaw crusher; costs of Jaw crusher; Go to Product Center. uses of pulveriser, impact crusher, coconut shell pulverizer

PE-300 Small Stone Jaw Crusher Crusher for Calcium Carbonate

1.Product Description PE300x500 details PE300x500 H engtong Model PE300x500 jaw crusher feeding size is 255 mm, output size is 3 0-60 mm, capacity is 25-30 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction

Crushing in Mineral Processing

2015年12月26日Primary crushers are designed so that the maximum size that can be presented to the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4 :1 and 9 : 1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3 :1 to 10 :1.

Big capacity jaw crusher for sale Calcium Carbonate Grinding

Jaw Crusher. Capacity:1-100 t/h. Feeding size:125-480 mm. Output Size:10-160 mm. Jaw crusher is mainly used in the industries of metallurgy, mining, chemical, cement, construction, refractory materials and ceramics, suitable to crush hard and soft ores with compressive strength less than 320 MPa. This machine can break material s into. Inquiry

Crusher For Sale Various TypesModels: Jaw Crusher, Cone crusher..

And screen crusher is the machine to produce aggregates. As time goes by, it has developed many crusher machine types to suit different demands, such as jaw crusher, cone crusher, hammer crusher, impact crusher, hydraulic crusher, mobile crusher, VSI crusher and so on. For example, VSI crusher can produce sands.

What Are Jaw Crushers and How Do They Work? Oreflow

2019年3月28日The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

Calcium Carbonate Grinding Process Mining, Crushing,

2013年5月9日2.Calcium carbonate milling equipment is easy to operate and maintain. 3.Production can meet the needs of the calcium carbonate processing equipment unit time. 4.Calcium carbonate milling equipment must also meet the needs of environmental protection. ? Limestone Crushing Production Line. Iron ore processing and mineral

Crusher an overview ScienceDirect Topics

The common primary crushers are of jaw and gyratory types. The jaw crusher reduces the size of large rocks by dropping them into a “V”-shaped mouth at the top of the crusher chamber. This is created between one fixed rigid jaw and a pivoting swing jaw set at acute angles to each other.

Jaw Crusher in Crushing Calcium Carbide -- YIFAN Machinery

2013年4月3日Calcium carbide crusher is mainly applied to the industries like mining ores, construction aggregates, railway and chemistry for crushing granite, limestone, cobblestone, basalt and iron ore, etc. The current typical crushing technique is PE600*900 jaw crusher + PE250*1200 + fine crusher. In order to achieve the goal of calcium