Grinding Table Case Sea Sand Hydrocyclone

How to resolve the most common hydrocyclone problems Weir

Manipulating water and pressure. The primary ways the plant metallurgist can change or alter the hydrocyclone’s classification is to vary the cyclone feed dilution water or adjust

Hydrocyclone Separators Evoqua

Consider a separator's use where any source of water contains contaminants with a weight of 2.6 specific gravity or higher, such as well water to remove sand. Separators are

进一步探索

Hydrocyclone DesignSizing Parameters Calculations How Cyclone Separator Works YouTube根据热度为您推荐•反馈

China Hydrocyclone mining sea sand cyclone separator factory

China Hydrocyclone mining sea sand cyclone separator factory Condition:New Origin:China Other name:Hydro cyclone or cyclone Model: FX, XC etc Used for:

Hydrocyclone Hydrocyclone Separator Working

Hydrocyclones first appeared in dutch in the late 1800s, Hidrociclon is an equipment that uses rotary current to classify, separate or sort coarse particles of sewage. It widely used

Hydrocyclone Working Principle Mineral Processing

2015年8月6日Hydrocyclone Working Principle. The centre of this spiral is called the VORTEX. The purpose of the apex is to cause internal pressure for the cyclone and to

Table 9 from Modelling and Performance Analysis of

DOI: 10.4314/tjs.v48i2.24 Corpus ID: ; Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine @article{Wikedzi2022ModellingAP,

Separate Sand and Clay with hydrocyclones Grinding

We are using hydrocyclones to separate sandclay. But these hydrocyclones are not performing well. We are using Stubby hydrocyclones so more amount of sand is

Table 3: Effect of grinding with sterile sea sand on the

Results of physical and chemical treatments are shown in (Tables 3,4,5 and 6). Data obtained in Table 3 clearly indicate that grinding yeast cells with sterile sea sand in

Table 3 from Modelling and Performance Analysis of

DOI: 10.4314/tjs.v48i2.24 Corpus ID: ; Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine @article{Wikedzi2022ModellingAP,

Hydrocyclone technology for breaking consolidation and sand

2021年12月1日Experiment setup and flow diagram: 1-screw pump; 2-water storage tank; 3-bypass valve; 4-flow meter; 5-pressure gauge; 6-bypass valve; 7-main valve; 8-feeder; 9-discharge valve; 10-hydrocyclone; 11-stocker; 12-water circulation purification system. Download : Download high-res image (135KB) Download : Download full-size image

(PDF) Design, Fabrication and Testing Of Hydrocyclone

2019年9月26日Hydrocyclone is a simple mechanical device, with no moving parts, where solid particles are separated from liquid with very little head loss. As its name describes, it uses a cyclone or...

How to resolve the most common hydrocyclone problems Weir

Manipulating water and pressure. The primary ways the plant metallurgist can change or alter the hydrocyclone’s classification is to vary the cyclone feed dilution water or adjust the hydrocyclone’s operating pressure. Producing a finer classification in hydrocyclones requires additional dilution water to lower the feed density of the

FILTRATION HYDROCYCLONE SAND SEPARATORS Netafim

4 • HYDROCYCLONE SAND SEPARATORS OPERATION, INSTALLATIONMAINTENANCE GUIDE INSTALLATION GUIDELINES • Install and connect the Hydrocyclone vertically with the Sedimentation Tank underneath the Hydrocyclone. • Special attention must be given to the correct flow direction: horizontal inlet and top

China Hydrocyclone mining sea sand cyclone separator factory

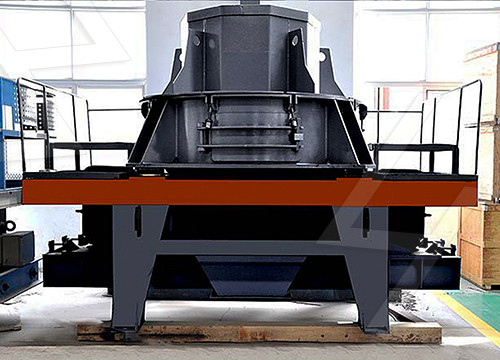

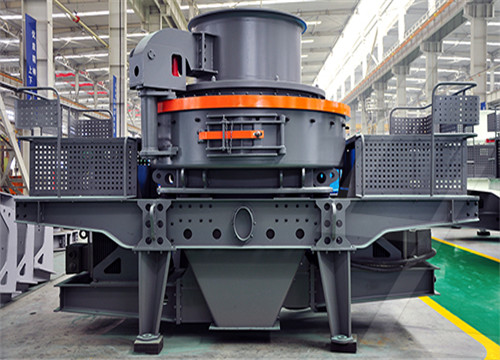

Hydrocyclone is also called cyclone separator, It is a kind of equipment that classifies pulp by centrifugal force. Hydro cyclone has replaced mechanical classifiers in many modern grinding plants,as they are more efficient, especially in the finer size ranges,they also need less floor space and consume less power.

Modelling and Performance Analysis of Hydrocyclones: The

Hydrocyclones are the standard classifiers used in wet closed grinding circuits in mineral processing plants and are chosen due to their simple design, low cost, easy operation, and low maintenance requirements. Due to their significance, many researchers have attempted to

IMPROVEMENTS OF EFFICIENT CLASSIFICATION WITH HIGH

The grinding circuit consisted of 14.5’x 23.5’, Marcy ball mill operating in closed circuit with GMax D-26 hydrocyclone nest with a circulating load of 260 as per figure 3. Table 3 shows % product size distribution with the circuit operated by hydrocylones. Microns Stack Sizer Feed Stack Sizer Oversize Stack Sizer Undersize % Pass % Pass % Pass

Hydrocyclone in Silica Sand Processing JXSC Machine

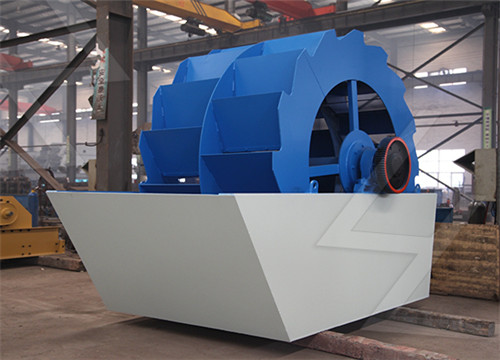

2019年4月4日The hydrocyclone is a device for separating and removing substances such as heavier coarse-grained silt from sewage, and sometimes used for mud dewatering. It is divided into two types: pressure type hydro cyclone separator and gravity type. It is usually made of a circular column structure or metal tube.

Hydrocyclone Sand Separator Netafim

Specially designed: Conical rubber protection to protect the cone from erosion Flushing frequency reduction: large holding capacity of sedimentation tank reduces flushing frequency Maximum anti-corrosion: Protection with durable long-lasting coating materials Maximum operating pressure: 10 bar (145 psi)

Technical specifications of the JHF025 hydrocyclone filter.

Smaller suspended solid removals observed by hydro-cyclone (8.90 % and 20.47 % with freshwater and effluent, respectively) and sand filter (9.77 % and 4.89 % with freshwater and effluent

Table 7 from Modelling and Performance Analysis of Hydrocyclones

DOI: 10.4314/tjs.v48i2.24 Corpus ID: ; Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine @article{Wikedzi2022ModellingAP, title={Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine}, author={Alphonce Wendelin Wikedzi and Thomas M{\"u}tze}, journal={Tanzania

The Weir Group Engineered Solutions For Industrial Markets

The Weir Group Engineered Solutions For Industrial Markets

15-thing every Extractive Metallurgist should know about Hydrocyclone

2020年6月16日In the case of Hydrocyclone, there is only one inlet and two outlets. Hence the grade of the inlet is equal to combine grade of the outlet material. Hydrocyclone is designed to operate on the...

Table 3 from Modelling and Performance Analysis of Hydrocyclones

DOI: 10.4314/tjs.v48i2.24 Corpus ID: ; Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine @article{Wikedzi2022ModellingAP, title={Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine}, author={Alphonce Wendelin Wikedzi and Thomas M{\"u}tze}, journal={Tanzania

How to resolve the most common hydrocyclone problems Weir

Manipulating water and pressure. The primary ways the plant metallurgist can change or alter the hydrocyclone’s classification is to vary the cyclone feed dilution water or adjust the hydrocyclone’s operating pressure. Producing a finer classification in hydrocyclones requires additional dilution water to lower the feed density of the

FILTRATION HYDROCYCLONE SAND SEPARATORS Netafim

4 • HYDROCYCLONE SAND SEPARATORS OPERATION, INSTALLATIONMAINTENANCE GUIDE INSTALLATION GUIDELINES • Install and connect the Hydrocyclone vertically with the Sedimentation Tank underneath the Hydrocyclone. • Special attention must be given to the correct flow direction: horizontal inlet and top

Modelling and Performance Analysis of Hydrocyclones: The

Hydrocyclones are the standard classifiers used in wet closed grinding circuits in mineral processing plants and are chosen due to their simple design, low cost, easy operation, and low maintenance requirements. Due to their significance, many researchers have attempted to

(PDF) Optimization and performance of grinding circuits: the case

2020年1月16日The analysis of survey data revealed inefficient grinding operation characterized by ball mill product (x P 80 > 400 µm) coarser than designed and higher hydrocyclone cut sizes (x T > 200 µm), too.

China Hydrocyclone mining sea sand cyclone separator factory

Hydrocyclone is also called cyclone separator, It is a kind of equipment that classifies pulp by centrifugal force. Hydro cyclone has replaced mechanical classifiers in many modern grinding plants,as they are more efficient, especially in the finer size ranges,they also need less floor space and consume less power.

Technical specifications of the JHF025 hydrocyclone filter.

Two drip irrigation systems with a hydro-cyclone filter, sand filter and screen filter for using freshwater (control treatment) and fish farm effluent were tested in Kurdistan province (northwest...

Hydrocyclone Sand Separator Netafim

Specially designed: Conical rubber protection to protect the cone from erosion Flushing frequency reduction: large holding capacity of sedimentation tank reduces flushing frequency Maximum anti-corrosion: Protection with durable long-lasting coating materials Maximum operating pressure: 10 bar (145 psi)

IMPROVEMENTS OF EFFICIENT CLASSIFICATION WITH HIGH

The grinding circuit consisted of 14.5’x 23.5’, Marcy ball mill operating in closed circuit with GMax D-26 hydrocyclone nest with a circulating load of 260 as per figure 3. Table 3 shows % product size distribution with the circuit operated by hydrocylones. Microns Stack Sizer Feed Stack Sizer Oversize Stack Sizer Undersize % Pass % Pass % Pass

15-thing every Extractive Metallurgist should know about Hydrocyclone

2020年6月16日In the case of Hydrocyclone, there is only one inlet and two outlets. Hence the grade of the inlet is equal to combine grade of the outlet material. Hydrocyclone is designed to operate on the...

Table 7 from Modelling and Performance Analysis of Hydrocyclones

DOI: 10.4314/tjs.v48i2.24 Corpus ID: ; Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine @article{Wikedzi2022ModellingAP, title={Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine}, author={Alphonce Wendelin Wikedzi and Thomas M{\"u}tze}, journal={Tanzania

Chapter M MODELLING, SIMULATION, OPTIMIZATION

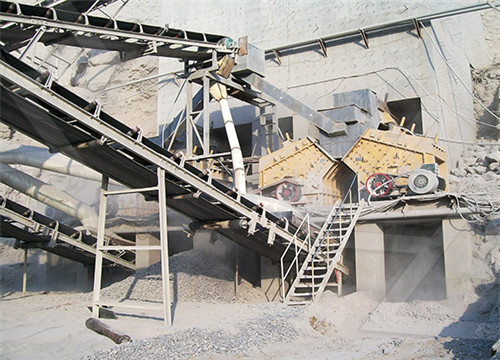

1.1 Grinding circuit sampling A sampling campaign from grinding circuit was planned to assess its performance under the current operating conditions. Presently, particles with a size greater than90 Pm enter to underflow stream and are recirculated to Semi-Autogenous Grinding (SAG) mill. The hydrocyclone overflow first passes through a

The Weir Group Engineered Solutions For Industrial Markets

The Weir Group Engineered Solutions For Industrial Markets

Table 3 from Modelling and Performance Analysis of Hydrocyclones

DOI: 10.4314/tjs.v48i2.24 Corpus ID: ; Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine @article{Wikedzi2022ModellingAP, title={Modelling and Performance Analysis of Hydrocyclones: The Case of Buzwagi Gold Mine}, author={Alphonce Wendelin Wikedzi and Thomas M{\"u}tze}, journal={Tanzania

McLanahan Agricultural Hydrocyclones an Effective Solution for Sand

Agricultural Hydrocyclones increase sand recovery in conventional sand separation systems by 5 to 10%. Depending on the gradation of sand the dairy is using, Hydrocyclones can increase overall sand recovery to as high as 95%. Higher sand recovery rates mean dairies can recycle more sand and spend less money buying new