How To Manufactured Crusher Machine

Jaw Rock Crusher BUILD Ep.5 YouTube

2021年8月20日12K 1.2M views 1 year ago #donndiy #rockcrusher #homemade Fabricating a jaw rock crusher from scratch. Making the toggle plate mount and fabricating a dedicated trailer using scrap

Jaw Crushers McLanahan

The narrower bottom opening of the crushing chamber is used to size the discharge material. A toggle plate and tension rods hold the pitman tight near the bottom of the

进一步探索

Jaw Crushers Best Models for 2023 911MetallurgistView Jaw Crushers for Sale in Australia Machines4u根据热度为您推荐•反馈

Design and Construction of Rock Crushing Machine from

need to adapt the jaw crusher technology to make it suitable and readily maintainable within the Nigerian mining industry. This must be achieved without any compromise as regard

4 Types of Stone Crushers' Maintenance and Efficient

Automatic Electric Can Crusher DIY YouTube

2021年10月14日This video includes the more complete details related to the building of an electric can crusher. The device was completed as a high school physics project in 2018 with my oldest

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

manufactured and transformed into a machine that would help in waste management. The crushing of used cans will also ensure that the cans are not used beyond the self-life of

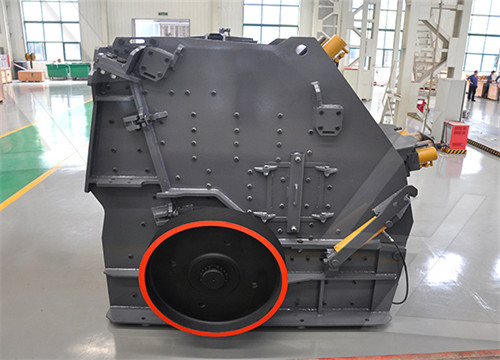

Stone Crusher ConeJaw Crushers Machine

Stone Crusher JXSC company stonerock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing planthammer crushing which can crush

A Fully Automatic Electric Can Crusher Hackaday

2019年1月13日At its heart is a 120V AC powered linear actuator, which crushes a can held in a welded steel guide. As the can is crushed it drops into a waiting bin, and when the actuator retracts a fresh can

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one

Rock Crusher MachinesPulverizers Williams Crusher

Most rock crushers use a container known as a hopper to hold the rock. Then, gravity feeds the rock into the crusher where it is reduced. A belt feeder can also be used to constantly feed the rock into the crusher. Once in the crusher, rock is pressed into smaller pieces that fit through a hole.

Design and Construction of Rock Crushing Machine from

need to adapt the jaw crusher technology to make it suitable and readily maintainable within the Nigerian mining industry. This must be achieved without any compromise as regard the machine performance and suitability of its operation. The shaft of a typical jaw crusher machine is made of hardened steel (high carbon steel).

Jaw Crusher for Primary Crushing Fote Machinery

1 Working principle of single toggle jaw crushers is that swing jaw plate that’s moving up/ down as the flywheel rotated by the motor. 2 The eccentric is located at the top of the swinging jaw, which makes the jaw can

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

manufactured and transformed into a machine that would help in waste management. The crushing of used cans will also ensure that the cans are not used beyond the self-life of the metals. Therefore this stone will prove to be a useful asset in many ways. We have designed the crushing machine using Modelling software’s.

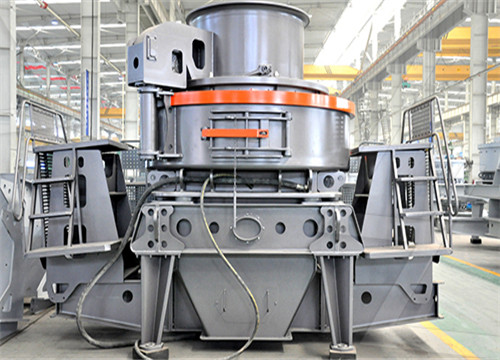

Stone Crusher ConeJaw Crushers Machine

The gyratory crusher is a large scale crushing machine which uses the gyratory movement of the crushing cone in the crushing cavity to extrude, squeeze and bend the materials. When the shaft sleeve rotates, the

Crusher Machine manufacturerssuppliers Made-in-China

New Technology and Best Installation Service Plastic Crusher Machine Prices in China, China Manufacturer Plastic Crusher Machine. US$ 1000-100000 / Piece. (FOB Price)

A Fully Automatic Electric Can Crusher Hackaday

2019年1月13日At its heart is a 120V AC powered linear actuator, which crushes a can held in a welded steel guide. As the can is crushed it drops into a waiting bin, and when the actuator retracts a fresh can

Glass to Sand Crushers WasteCare

GLASS SAND CRUSHER FEATURES. Simple, easy to Operate and quiet. Handles wine and spirit bottles. Crushing time of 3 5 seconds per bottle. Low operating height and s mall Footprint. Works with 20 Liter / 5 Gallon

Bone Grinder Bone Crusher Machine Crushing

2020年12月30日The commercial bone grinder machine is the high-efficiency crushing equipment for crushing various animal bones into fine bone fragments, bone mud, and bone powder. The bone grinder

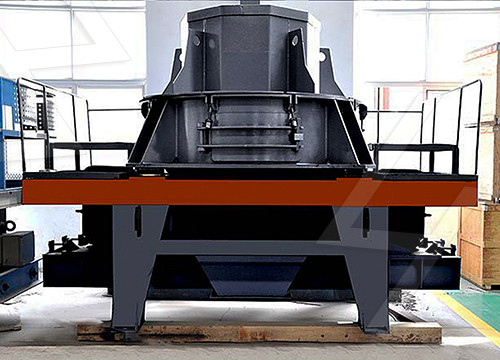

6 Types of Sand Making Machine and How to Choose the Best

2023年2月28日The HVI sand making machine can process 70-585 THP with a maximum feeding size of 55 mm. Adopting the best material impact angle design of crushing chamber, it can realize sand making and shaping, so

DIY Homemade Rock Crusher 911Metallurgist

2020年7月28日The 911JAC12K MINI Rock Crusher is our ‘most small’ rock crusher for the smallest budget. It contains all the high quality precision pre-cut and ready to weld machined parts of a small jaw

Your Best Metal Crusher Machine Manufacturer in China

The crushing material from our metal shredder machine goes through a vibration feeder, belt conveyor, magnetic sorting system. 2. Separate the iron metal, non-ferrous metal, and non-metallic objects, and send them out by their respective conveyors for stacking. 3.

All crusher types for your reduction needs Metso Outotec

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso Outotec offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers optimized for any size reduction need.

Crushers an overview ScienceDirect Topics

Roller crusher: This crusher is composed of two cylinders rotating in opposite directions around two parallel axes. • Rotary bottom crusher. The main manufacturing steps are as follows: • Site selection and separation • Weighting and control • Fragmentation • Primary crushing • Steel separation by magnetic means •

A Fully Automatic Electric Can Crusher Hackaday

2019年1月13日At its heart is a 120V AC powered linear actuator, which crushes a can held in a welded steel guide. As the can is crushed it drops into a waiting bin, and when the actuator retracts a fresh can

Jaw Crusher for Primary Crushing Fote Machinery

1 Working principle of single toggle jaw crushers is that swing jaw plate that’s moving up/ down as the flywheel rotated by the motor. 2 The eccentric is located at the top of the swinging jaw, which makes the jaw can

Crusher Machine manufacturerssuppliers Made-in-China

New Technology and Best Installation Service Plastic Crusher Machine Prices in China, China Manufacturer Plastic Crusher Machine. US$ 1000-100000 / Piece. (FOB Price)

Your Best Metal Crusher Machine Manufacturer in

The crushing material from our metal shredder machine goes through a vibration feeder, belt conveyor, magnetic sorting system. 2. Separate the iron metal, non-ferrous metal, and non-metallic objects, and send them

The Rebel Crusher Crush, Screen and Track RR Equipment

The REBEL CRUSHER can tackle nearly ANY application; small, medium and large! It has the ability to pre-screen, crush, and separate crushed material into three (3) separate stock piles while removing rebar, wire, and steel at the SAME TIME! Capable of tracking and crushing without stopping.

DIY Homemade Rock Crusher 911Metallurgist

2020年7月28日This 1″ x 2″ homemade rock crusher is mini in size but large in crushing performance. This small jaw crusher kit comes with full how-to-build instructions. HANDYMAN ALERT: The final assembly of

Glass to Sand Crushers WasteCare

GLASS SAND CRUSHER FEATURES. Simple, easy to Operate and quiet. Handles wine and spirit bottles. Crushing time of 3 5 seconds per bottle. Low operating height and s mall Footprint. Works with 20 Liter / 5 Gallon

Machine-made Sand Prospect, Using, Equipment

2021年8月24日The machine-made sand production line mainly includes a series of production links such as crushing, sand making, screening and sand washing.The equipment used include vibrating feeder, jaw

Bone Grinder Bone Crusher Machine Crushing

2020年12月30日The commercial bone grinder machine is the high-efficiency crushing equipment for crushing various animal bones into fine bone fragments, bone mud, and bone powder. The bone grinder

Rock Crusher Eastman Rock Crusher

In mining industry, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations. Metallurgy area, use crushers and grinding mills for

5 Best Can Crushers Mar. 2023 BestReviews

All can crushers need to be stable to do their job. This can either be achieved by mounting it to the wall or by the weight of the machine itself. Heavy floor models don’t require you to drill into your wall, but they do have a larger footprint and take up more room.

8 DIY Can Crusher Ideas DIYs Craftsy

2022年1月2日A fulcrum attached to the back clamp holds the machine open for loading cans. It's powered by your foot--just press the pedal to push down on the handles, which press down on the levers to pinch and crimp the cans before tossing them into a scrap bin. This can crusher should last for years. farmshow Simple Can Crusher:

What a Can Crusher Is and How it works DoRecycling

2014年10月27日The way how a can crusher works is pretty simple. Aluminum can crusher consists from a frame, handle with soft grip at the end, hinges, compressing plate and metal bolts that hold all mechanism together. These parts can be made from different materials, depending on the type of can crusher. Cheaper can crushers are made from