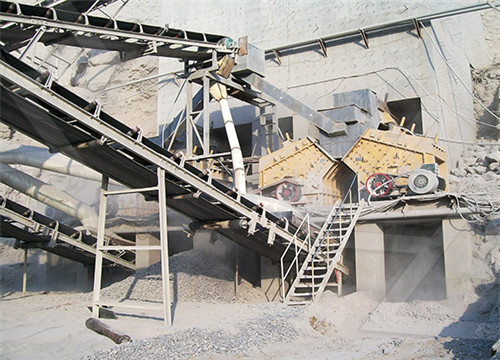

Crusher Cone Crusher Or Jaw Crusher Or Impact Crusher

How to Choose a Rock Crusher Sepro Aggregates

Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushersinclude vertical shaft

Jaw Crusher vs. Impact Crusher What's the difference?

2020年8月21日Aggregate equipment expert Dave Phelan goes in depth about two popular crushing options so you can decide which on is right for you. For more

Jaw Crusher VS Impact Crusher JXSC Machine

Application Jaw crushers are mainly used as primary crushers, it can crush

Jaw Crusher VS Cone Crusher Advantages and

Crushing PrincipleApplication FieldAdvantages and DisadvantagesCone rock crusher and Jaw stone crusher are a laminated crushing principle. Which is commonly known as the impact crushing principle The nature of crushing doesn’t change too much, although the actuator of crushing use of different structure. The cone crusher adopts the extrusion process between the grinding w在jxscmine上查看更多信息预计阅读时间:4 分钟

Impact vs cone crushers: Which is more effective? Quarry

2015年4月1日Impact crushing is also more eco-friendly and can help save energy. A cone crusher will require the installation of a downstream VSI to achieve a similar cubic shape as that of an impact crusher, ie

How Does a Jaw Crusher Work Jaw Crusher Kemper

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical

Jaw Crusher vs Cone Crusher: A Comparison Sepro

While cone crushers and jaw crushers both perform a similar job of breaking rocks, their approach and applications are quite different. Introducing The Jaw Crusher These burly

What is the difference between impact cone jaw crushers

2023年2月9日impact crusher Cone crushers, jaw crushers, and impact crushers are three different types of crushers that are used to handle different sized particles. Cone

Crushers (NewUsed Jaw Crushers, Impact Crushers,Cone

Crushers Print NewUsed Jaw Crushers, Impact Crushers,Cone Crushers for sale from manufacturers like Extec, , Sandvik, , and more. Rock Crushers,

Cone Crusher an overview ScienceDirect Topics

The concrete C&D waste recycling process of “impact crusher + cone crusher + hoop-roller grinder” is also capable of handling brick waste. In general, the secondary crushing using the cone crusher in this process with an enclosed crusher is a process of multicrushing, and the water content of waste will become an important affecting factor.

Jaw Crusher vs. Impact Crusher What's the difference?

2020年8月21日Aggregate equipment expert Dave Phelan goes in depth about two popular crushing options so you can decide which on is right for you. For more information on

How to Choose a Rock Crusher Sepro Aggregates

Jaw Crusher Applications. Jaw crushers generally have a 10:1 reduction ratio, so a standard 30×48 jaw crusher with a 30” opening will have a minimum closed side setting of three inches. While jaw crushers can be

Jaw Crusher vs Cone Crusher: A Comparison Sepro Aggregates

While cone crushers and jaw crushers both perform a similar job of breaking rocks, their approach and applications are quite different. Introducing The Jaw Crusher These burly machines act as a primary crusher for mining and processing ore. Two powerful jaws (one fixed, one moveable) are mounted in a “V” alignment.

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年2月15日The overall structure of the machine. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3 times higher than the jaw crusher with the same feeding opening size. A Larger machine means higher site costs . 4. Material handling.

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日Cone crusher looks like gyratory crusher but without a steep crushing chamber. Just like jaw crusher, it is also a compression type crusher whose reduction ratio is 4:1 to 6:1. When cone crusher works, it uses the force between moveable mantle and stationary bowl liner to crush material.

Type of crushers and their difference JXSC Mining

2019年12月10日Generally, jaw crushers are installed at this crushing stage. Some operations will need further crushing in secondary and tertiary crushing stages. These stages are used to better control and size the

Jaw, Cone, and Impact Crusher Plants ELRUS Aggregate

Our product line includes: ELRUS jaw crushers, cone and impact crushers in a range of sizes and configurations including: portable, modular and stationary to suit individual requirements. Primary Jaw Crusher Plants. ELRUS manufactures heavy-duty jaw crushers that have been stress relieved and machined for a close fit with other

Cone Crushers MEKA CrushingScreening Plants

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use

Which Crusher is needed to process Concrete? Luoyang Dahua

There are three commonly used and cost-effective types of equipment: jaw crusher, cone crusher and impact sand making machine. Jaw crusher: Jaw crusher is used in the coarse crushing stage in the production line. This crusher has stable operation, large crushing force, and wide applicability, it can break hundreds of materials for medium

Crushers (NewUsed Jaw Crushers, Impact Crushers,Cone Crushers

NewUsed Jaw Crushers, Impact Crushers,Cone Crushers for sale from manufacturers like Extec, , Sandvik, , and more. Rock Crushers, Concrete Crushers, Stone Crushers, and more. Exclusive US home of Evortle Crushers. Small concrete crushers available new! Financing available upon request.

What is the best type of crusher for hard rock?

2023年3月7日Jaw Crushers: These are designed to crush rock between two jaws, one of which is stationary and the other moves back and forth. Jaw crushers are often used for primary crushing of hard...

jaw crusher, cone crusher, impact crusher Mining Crushing

Mining Crushing Machinery, Milling Machinery and Sand Making Machines For Sale 【】 :https://api.whatsapp/send/?phone=

Crusher Aggregate Equipment For Sale MachineryTrader

2 之These machines come in three main types, jaw crusher, cone and gyratory crusher, and impact crusher. Jaw crushers, occasionally referred to as “toggle crushers,” are the most common type of crusher. Material is compressed between a moving piece of steel and a stationary piece. Cone crushers are compression crushers that use a

Cone Crusher an overview ScienceDirect Topics

The concrete C&D waste recycling process of “impact crusher + cone crusher + hoop-roller grinder” is also capable of handling brick waste. In general, the secondary crushing using the cone crusher in this process with an enclosed crusher is a process of multicrushing, and the water content of waste will become an important affecting factor.

When to Choose a Jaw Crusher vs. Cone crusher vs.

Applications Suitable for Jaw Crushers. Jaw crushers are typically used in a scenario that requires a reduction ratio of 10:1. A jaw crusher 30” opening has a 3-inch minimum closed side setting. Jaw crushers have diverse

Jaw Crusher vs Cone Crusher: A Comparison Sepro Aggregates

While cone crushers and jaw crushers both perform a similar job of breaking rocks, their approach and applications are quite different. Introducing The Jaw Crusher These burly machines act as a primary crusher for mining and processing ore. Two powerful jaws (one fixed, one moveable) are mounted in a “V” alignment.

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年2月15日Discharging size: The Jaw crusher is normally used for primary crushing which will give you a big crushing capacity and the output size is bigger but suitable for secondary crushing. While cone crusher is for secondary and tertiary crushing stages, thus having a smaller discharging size.

Type of crushers and their difference JXSC Mining

2019年12月10日Generally, jaw crushers are installed at this crushing stage. Some operations will need further crushing in secondary and tertiary crushing stages. These stages are used to better control and size the

What is the difference between Impact Crusher and Cone Crusher?

2021年12月8日Cone crushers are also used in the steel furnace slag industry, which is a much more abrasive slag than blast furnace. Impact crushers, initially, are less expensive than cone crushers. Although cone crushers are more expensive up front, they will require far less maintenance than impact crushers.

Crushers For Sale Near Me Equipment Trader

Packages starting as low as $29.95! Find a dealer. Crushers are an important part of many industrial and materials processing projects. They allow for the crushing of rocks into gravel, smaller rocks, or even miniscule dust. Equipment Trader’s website allows users to quickly search for the best models near to their zip code from the brands

Jaw, Cone, and Impact Crusher Plants ELRUS Aggregate

ELRUS Jaw, Cone and Impact Crushers ELRUS manufactures crushing equipment and provides Primary, Secondary, Tertiary and Quaternary aggregate processing solutions for Crushing applications in the aggregate, mineral, mining and recycling industries.

Cone Crushers MEKA CrushingScreening Plants

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use

Which Crusher is needed to process Concrete? Luoyang Dahua

There are three commonly used and cost-effective types of equipment: jaw crusher, cone crusher and impact sand making machine. Jaw crusher: Jaw crusher is used in the coarse crushing stage in the production line. This crusher has stable operation, large crushing force, and wide applicability, it can break hundreds of materials for medium

6 Granite Crushers for Efficient Granite Crushing Fote

2023年2月28日The impact crusher has the dual performance of crushing and shaping. Its product shape is better than that of cone crusher. In view of the serious wear of granite to the impact crusher, we do not use the

jaw crusher, cone crusher, impact crusher Mining Crushing

Mining Crushing Machinery, Milling Machinery and Sand Making Machines For Sale 【】 :https://api.whatsapp/send/?phone=

What is the best type of crusher for hard rock?

2023年3月7日Jaw Crushers: These are designed to crush rock between two jaws, one of which is stationary and the other moves back and forth. Jaw crushers are often used for primary crushing of hard...

Crusher Aggregate Equipment For Sale MachineryTrader

2 之These machines come in three main types, jaw crusher, cone and gyratory crusher, and impact crusher. Jaw crushers, occasionally referred to as “toggle crushers,” are the most common type of crusher. Material is compressed between a moving piece of steel and a stationary piece. Cone crushers are compression crushers that use a